Temperature controlled window of a plasma processing chamber component

A technology for plasma and processing chambers, which is applied in the field of temperature-controlled windows for plasma processing chamber components, and can solve the problems of increased heat flux of ceramic windows, aggravated thermal stress, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Time-varying thermal loads are at the heart of semiconductor wafer processing, where heat generation necessarily occurs on a discrete basis (wafer-to-wafer). Spatially varying thermal loads are also common in etch process modules where the density and proximity of the plasma to the part is non-uniform. Also, it is desirable that the components of the plasma processing chamber be at a certain temperature during plasma processing and that these components not be heated by the plasma until wafer processing begins. Circulating the hot liquid allows the first wafer to be processed without the first wafer effect, but as plasma processing continues, the components are heated by the plasma such that the components need to be cooled to the target high temperature, as in the Commonly Accepted Documents, which are hereby incorporated by reference in their entirety. as described in U.S. Published Patent Application No. 2008 / 0308228.

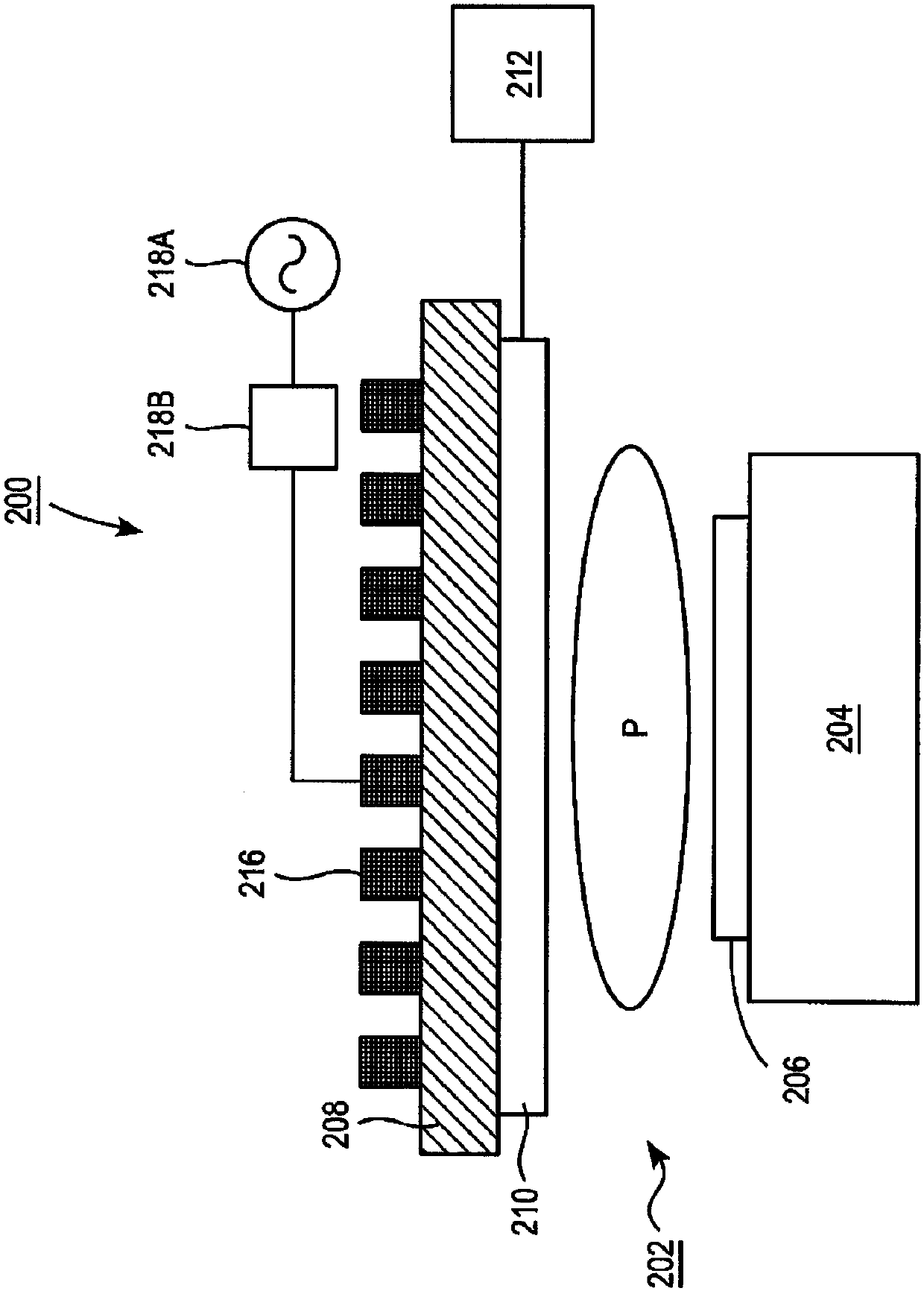

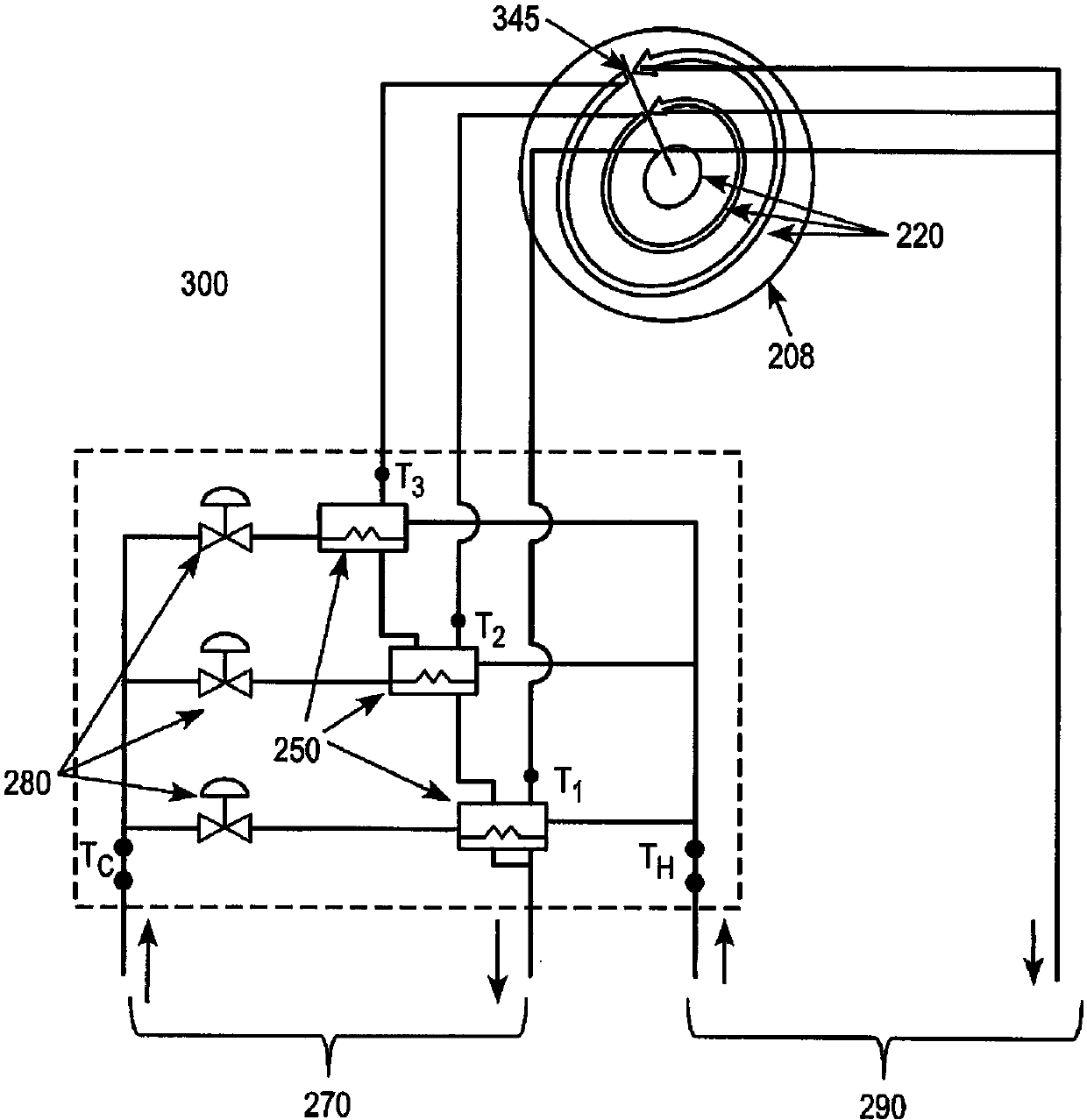

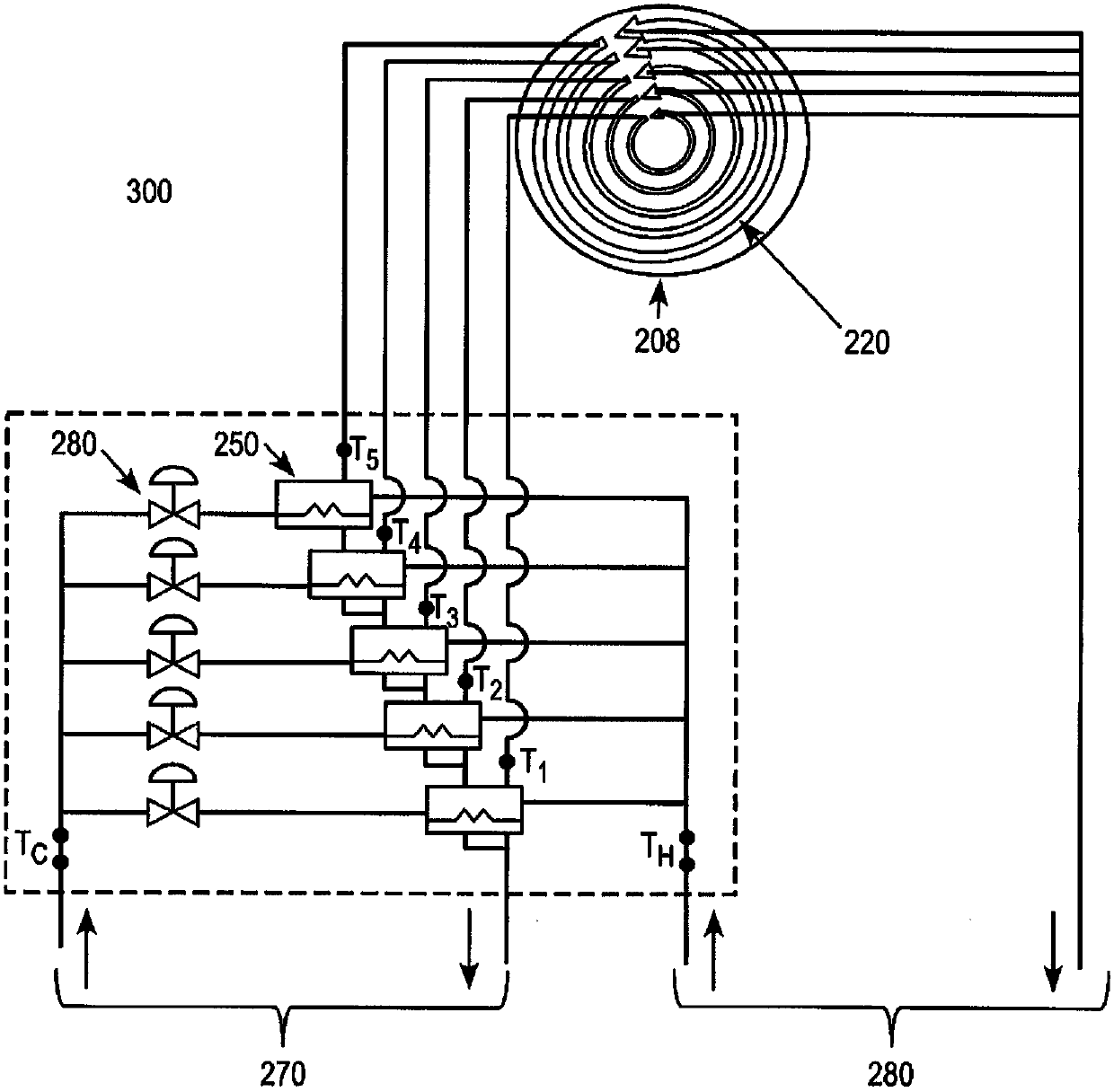

[0021] In one embodiment, as figure 1 As show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com