Al-based plated steel material and method for producing same

A manufacturing method and steel technology, applied in the direction of manufacturing tools, hot-dip plating process, metal material coating process, etc., to achieve the effect of excellent corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0091] Next, the effects of the present invention will be described using examples and comparative examples, but this example is merely an example for explaining the present invention and does not limit the present invention.

[0092] (Samples 1 to 7)

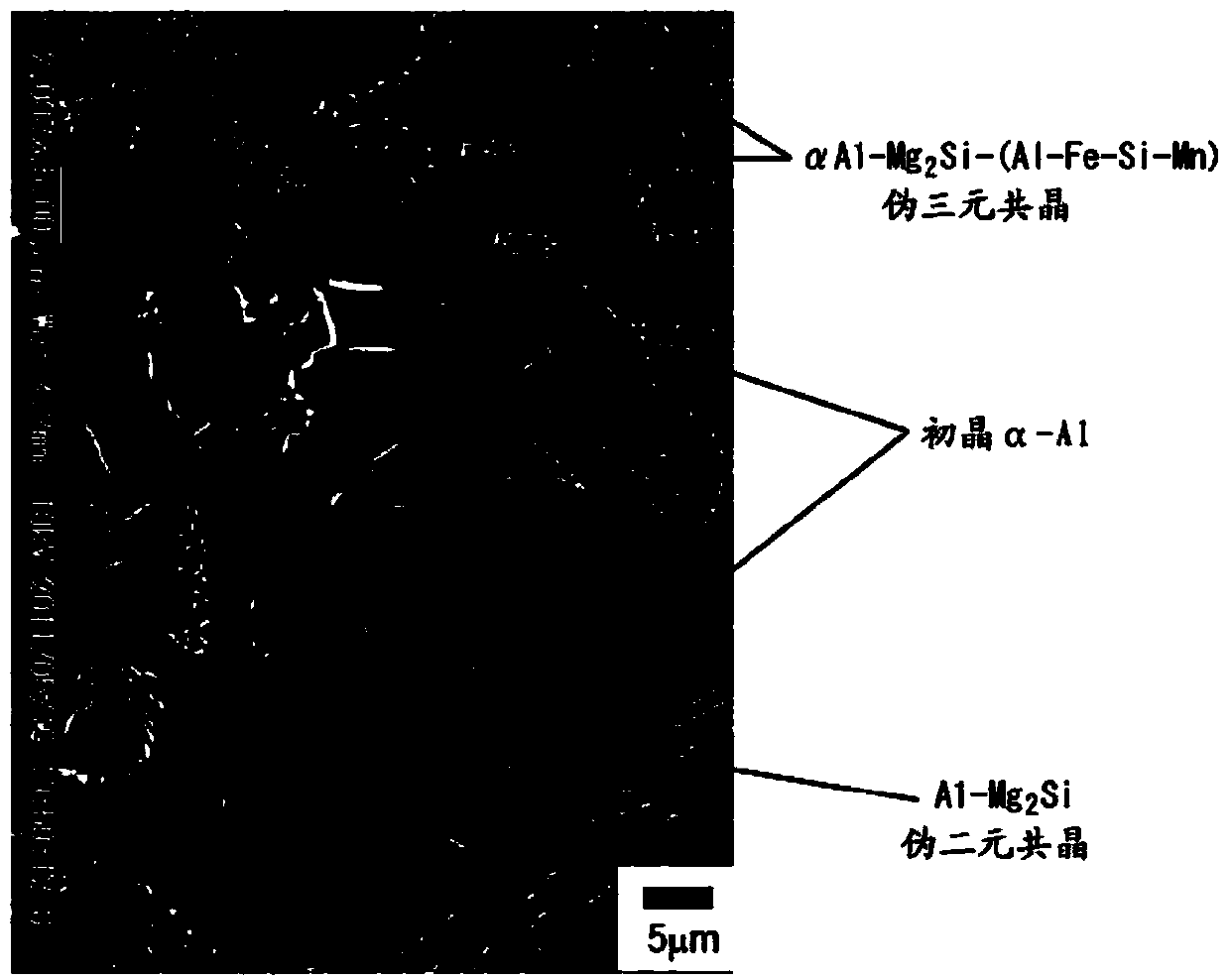

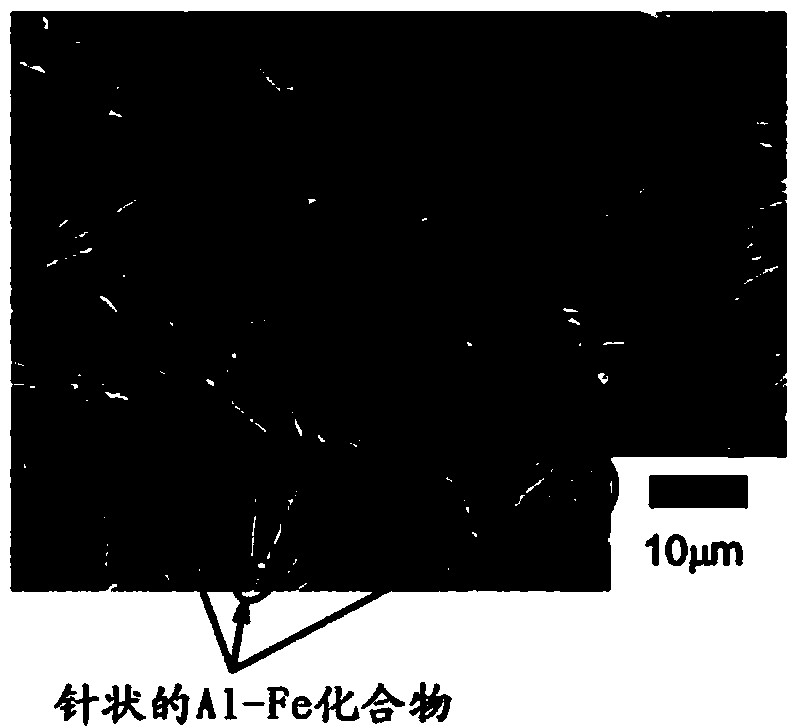

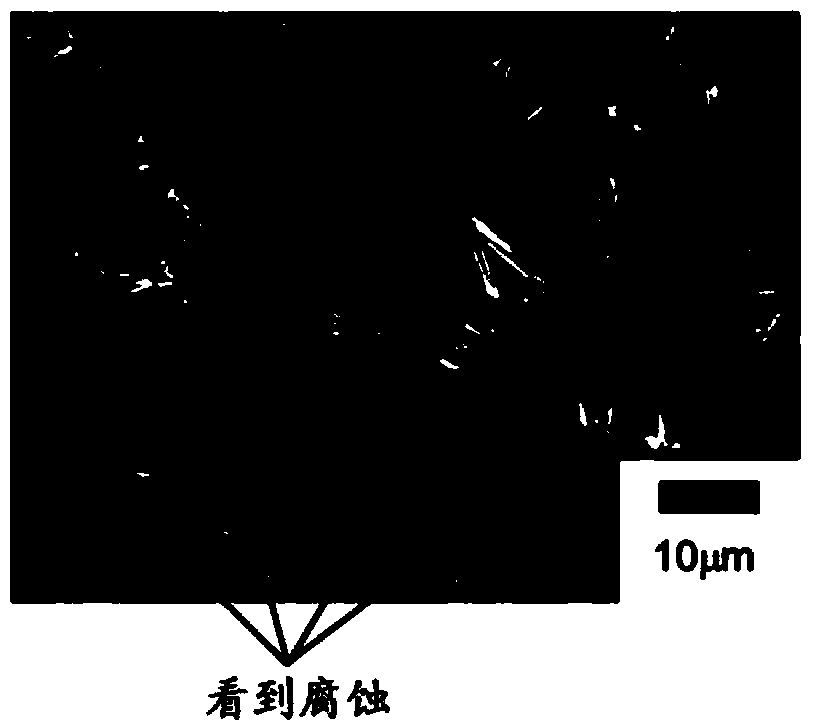

[0093] The cold-rolled steel sheet was annealed at 800° C. for 30 seconds in a reducing gas, and then immersed in a plating bath maintained at 680° C. for 5 seconds at a sheet temperature of 700° C. to perform hot-coating. After the hot-dip coating, the coating structure was controlled by adjusting the cooling rate (Table 1), and an Al-based plated steel sheet was produced. Table 1 shows the amount of plating deposited on each side of the obtained Al-based plated steel sheet, the composition of the plating, and the structure of the plating.

[0094] It should be noted that for the obtained plated steel sheet, the amount of plating material deposited was measured by gravimetric method, and the composition was analyzed by chemic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com