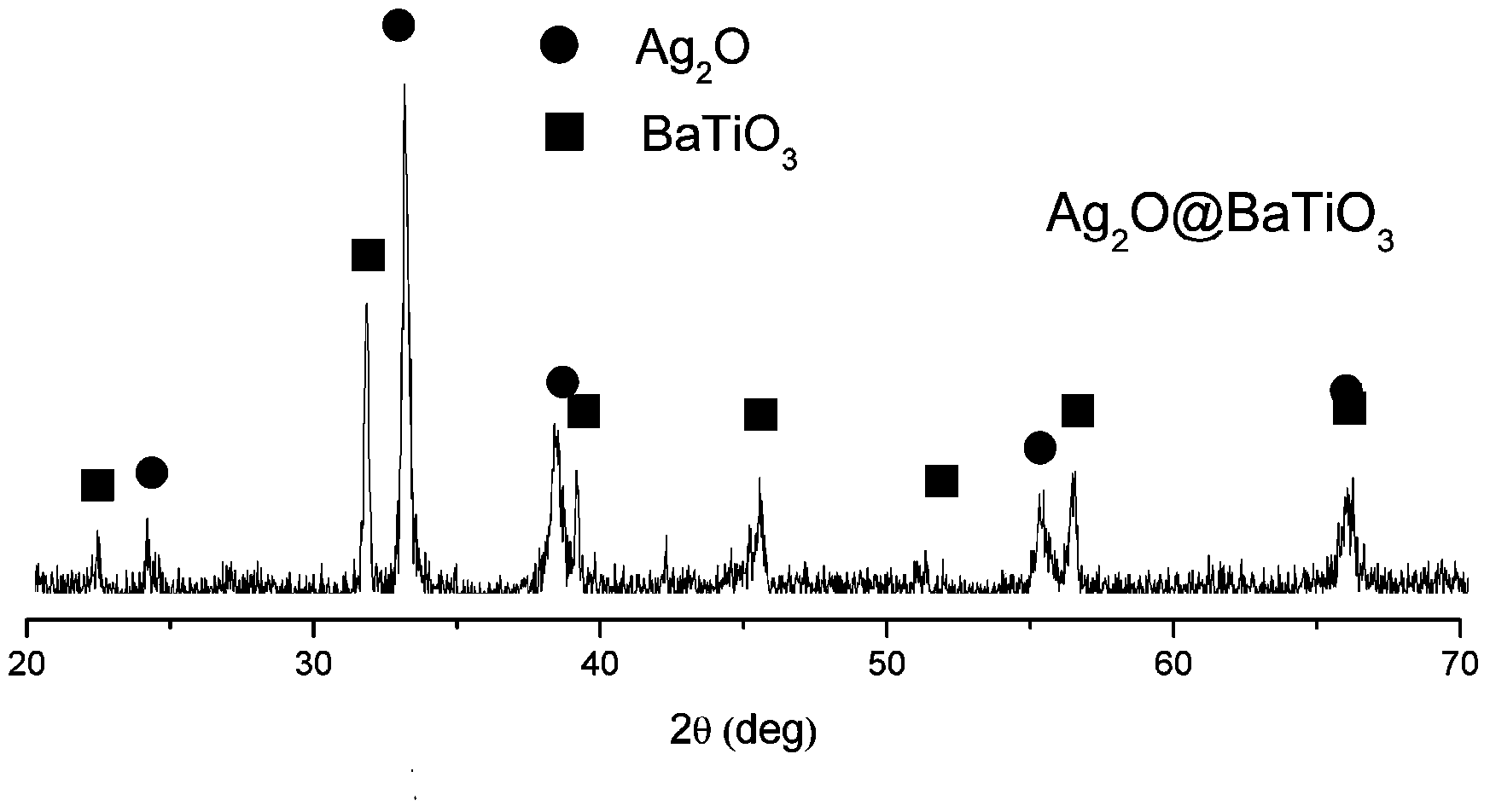

Silver oxide/barium titanate ultrasonic photo-catalyst and preparation method thereof

A photocatalyst, barium titanate technology, applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, chemical instrument and method, etc., to promote photocatalytic reaction activity, improve photocatalytic activity, effect of promoting separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

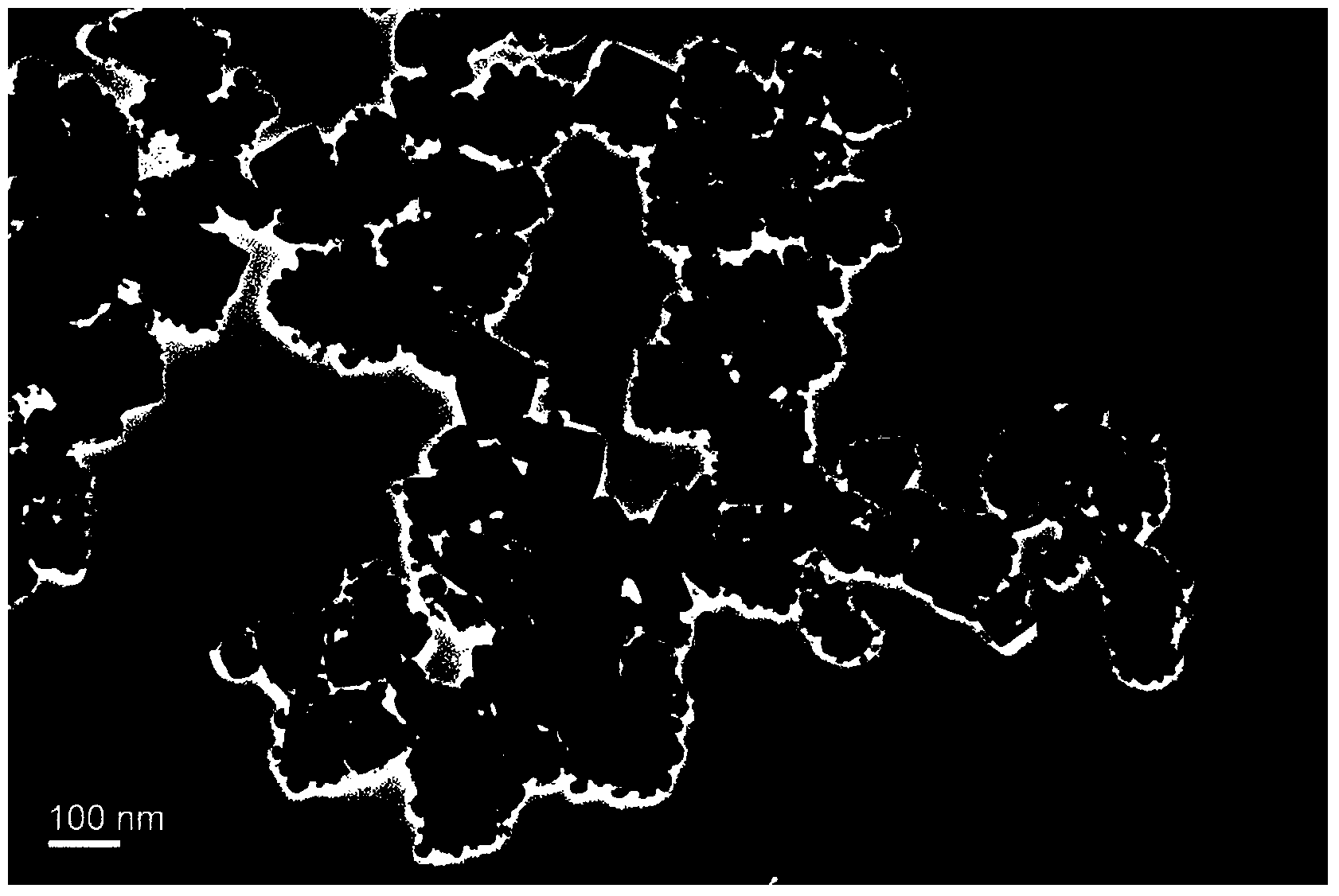

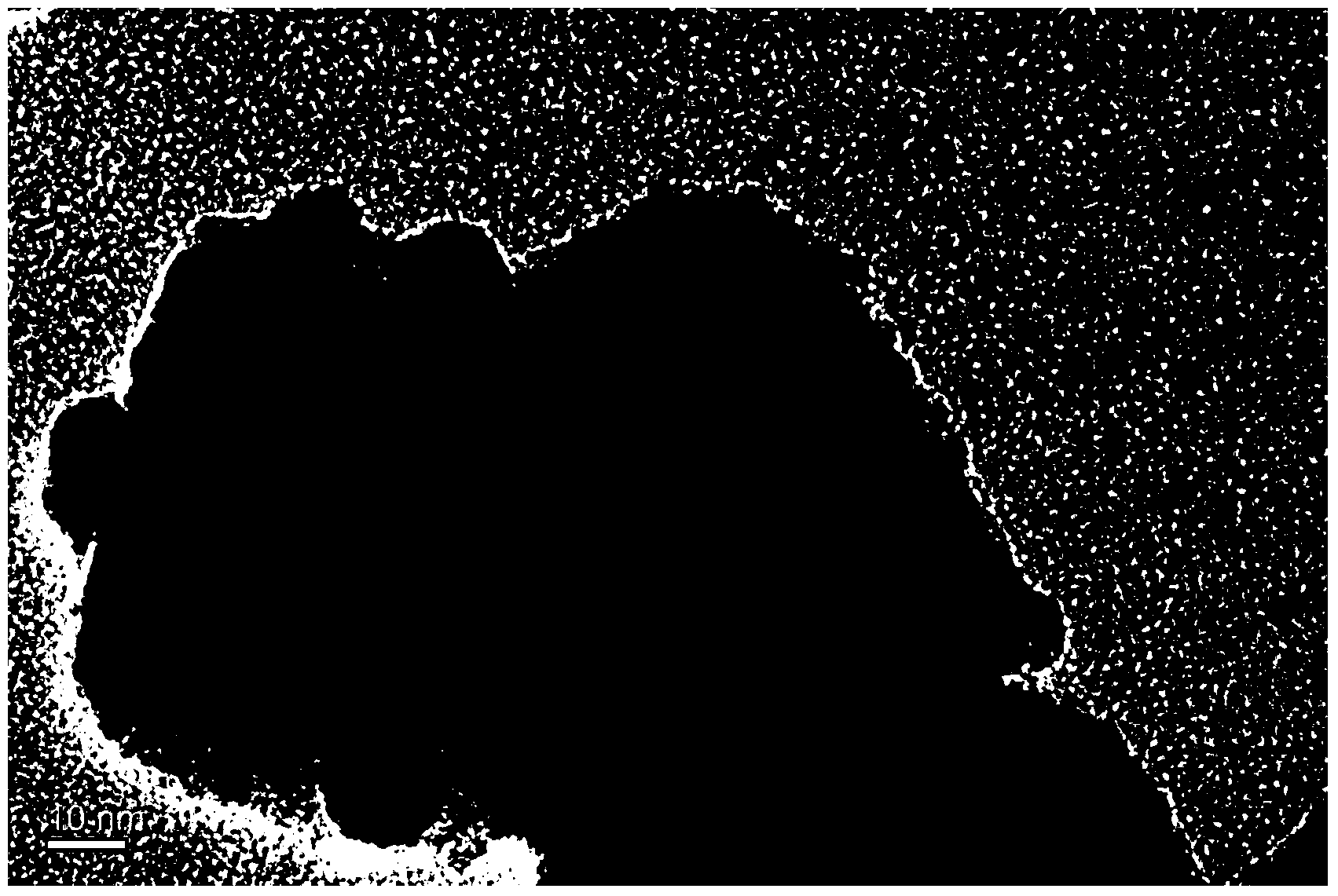

Method used

Image

Examples

Embodiment 1

[0021] ① Mix 20g of anhydrous hydroxide (NaOH / KOH=51.5:48.5), 0.6mmol BaCl 2 , 0.5 mmol nano-TiO 2 Add to the hydrothermal reaction kettle in turn, the filling degree is controlled at 20-30% of the reaction kettle volume, and stir evenly; then seal the hydrothermal reaction kettle, put it into the drying box, and control the hydrothermal temperature at 200°C, The reaction time was controlled at 48h. After the reaction was completed, it was naturally cooled to room temperature, and the obtained product was repeatedly washed with deionized water to neutrality, then suction filtered, and dried to obtain BaTiO 3 powder;

[0022] ② Weigh the BaTiO obtained in step ① 3 Powder 100mg, and dispersed in 100mL of water, ultrasonic stirring for 30min, the concentration of 1g / L of BaTiO 3 Suspension, the resulting solution is marked as A;

[0023] ③BaTiO by mass ratio 3 :Ag 2 The ratio of O=1:5, add the corresponding reaction amount of AgNO to the A solution under the condition of ul...

Embodiment 2

[0029] ① Mix 20g of anhydrous hydroxide (NaOH / KOH=51.5:48.5), 0.6mmol BaCl 2 , 0.5 mmol nano-TiO 2 Add to the hydrothermal reaction kettle one by one, stir evenly, and the filling degree is controlled at 20-30% of the reaction kettle volume; then seal the hydrothermal reaction kettle, put it into the drying box, control the hydrothermal temperature at 200°C, and react The time is controlled at 72h. After the reaction is completed, it is naturally cooled to room temperature, and the obtained product is repeatedly washed with deionized water until it is neutral, then suction filtered, and dried to obtain BaTiO 3 powder, ready to use;

[0030] ② Disperse 100mg of barium titanate powder obtained in step ① in 100mL of water, and ultrasonicate for 30min to obtain BaTiO 3 For suspensions with a concentration of 1g / L, the resulting solution is denoted as A;

[0031] ③ Add BaTiO to A solution by mass ratio 3 :Ag 2 The ratio of O=1:1 was added to the corresponding reaction amount o...

Embodiment 3

[0034] ① Mix 20g of anhydrous hydroxide (NaOH / KOH=51.5:48.5), 0.6mmol BaCl 2 , 0.5 mmol nano-TiO 2 Add to the hydrothermal reaction kettle one by one, stir evenly, and the filling degree is controlled at 20-30% of the reaction kettle volume; then seal the hydrothermal reaction kettle, put it into the drying box, control the hydrothermal temperature at 200°C, and react The time was controlled at 48h, and after the reaction was completed, it was naturally cooled to room temperature, and the obtained product was repeatedly washed with deionized water to neutrality, then suction filtered, and dried to obtain BaTiO 3 powder, ready to use;

[0035] ② Disperse 100mg of barium titanate powder obtained in step ① in 100mL of water, and ultrasonicate for 30min to obtain BaTiO 3 For suspensions with a concentration of 1g / L, the resulting solution is denoted as A;

[0036] ③ Add BaTiO to A solution by mass ratio 3 :Ag 2 The ratio of O=3:2 was added to the corresponding reaction amount...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com