A deep hole drilling machine

A deep hole drilling machine and drilling tool technology, which is applied in the direction of boring/drilling, drilling/drilling equipment, and drilling templates for workpieces, etc., which can solve the problem of low radial precision of hole processing and large feed inertia of workpieces , Unable to correct problems such as deflection, to achieve the effect of improving machining accuracy, prolonging life, and improving temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings.

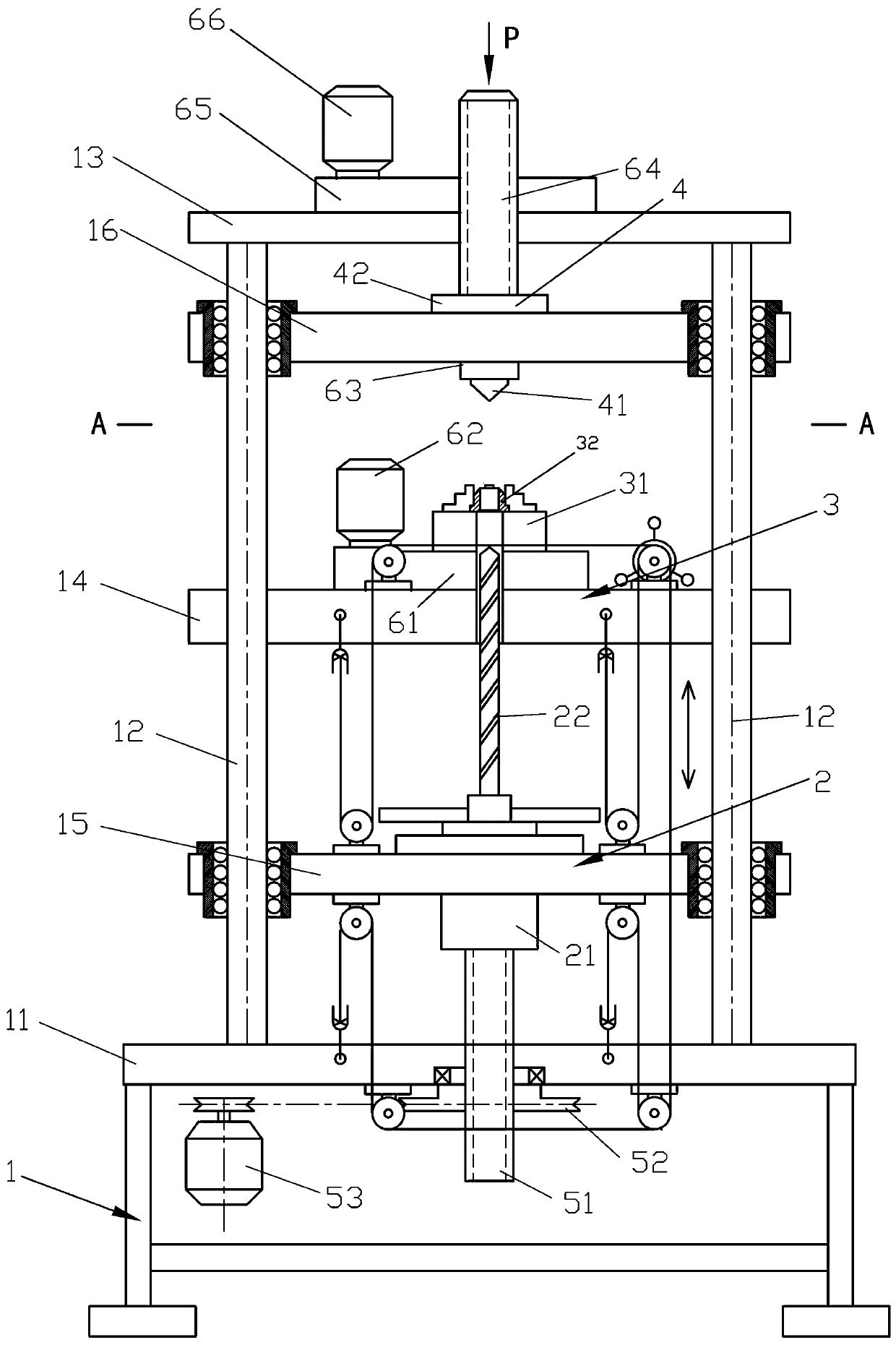

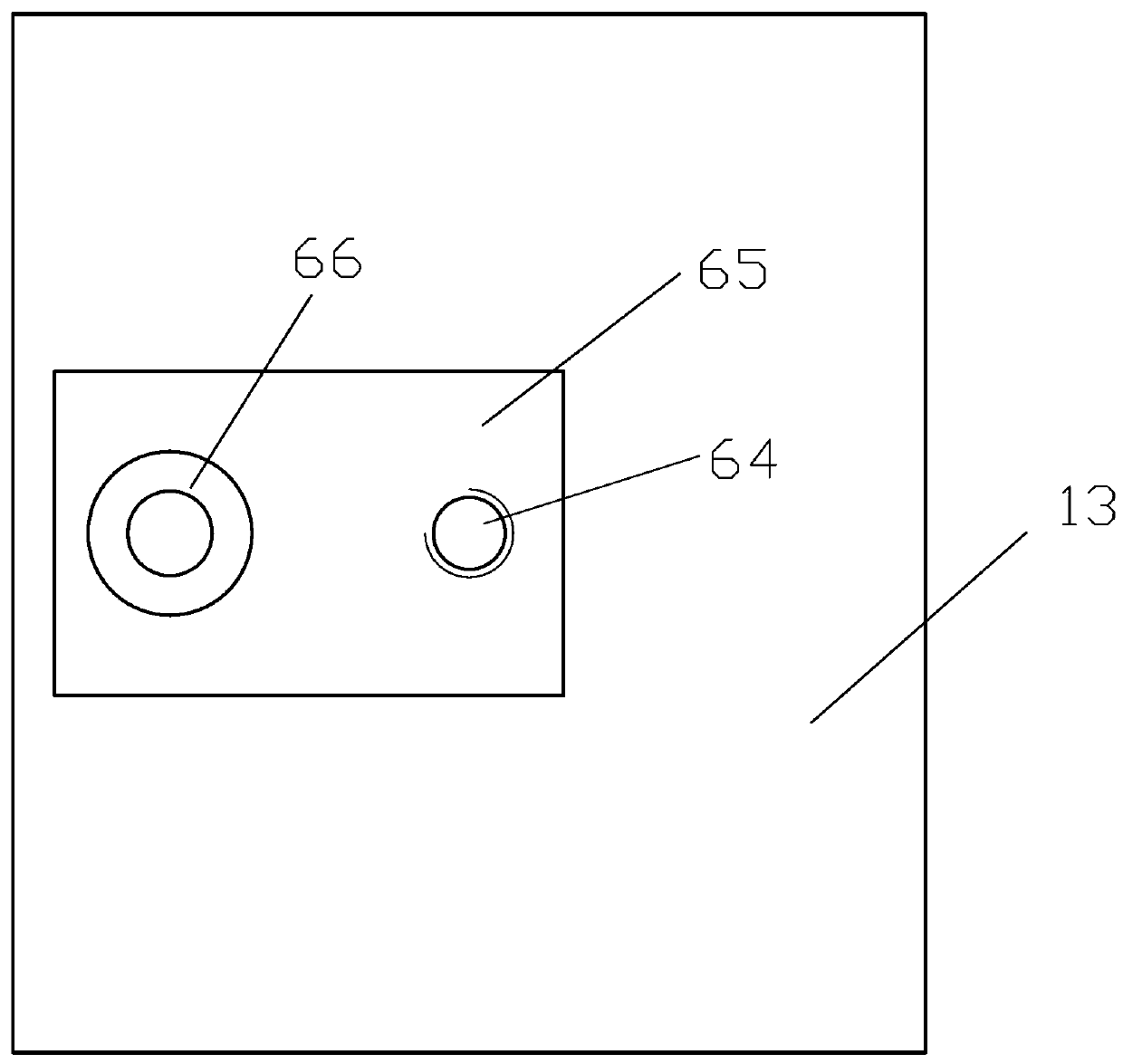

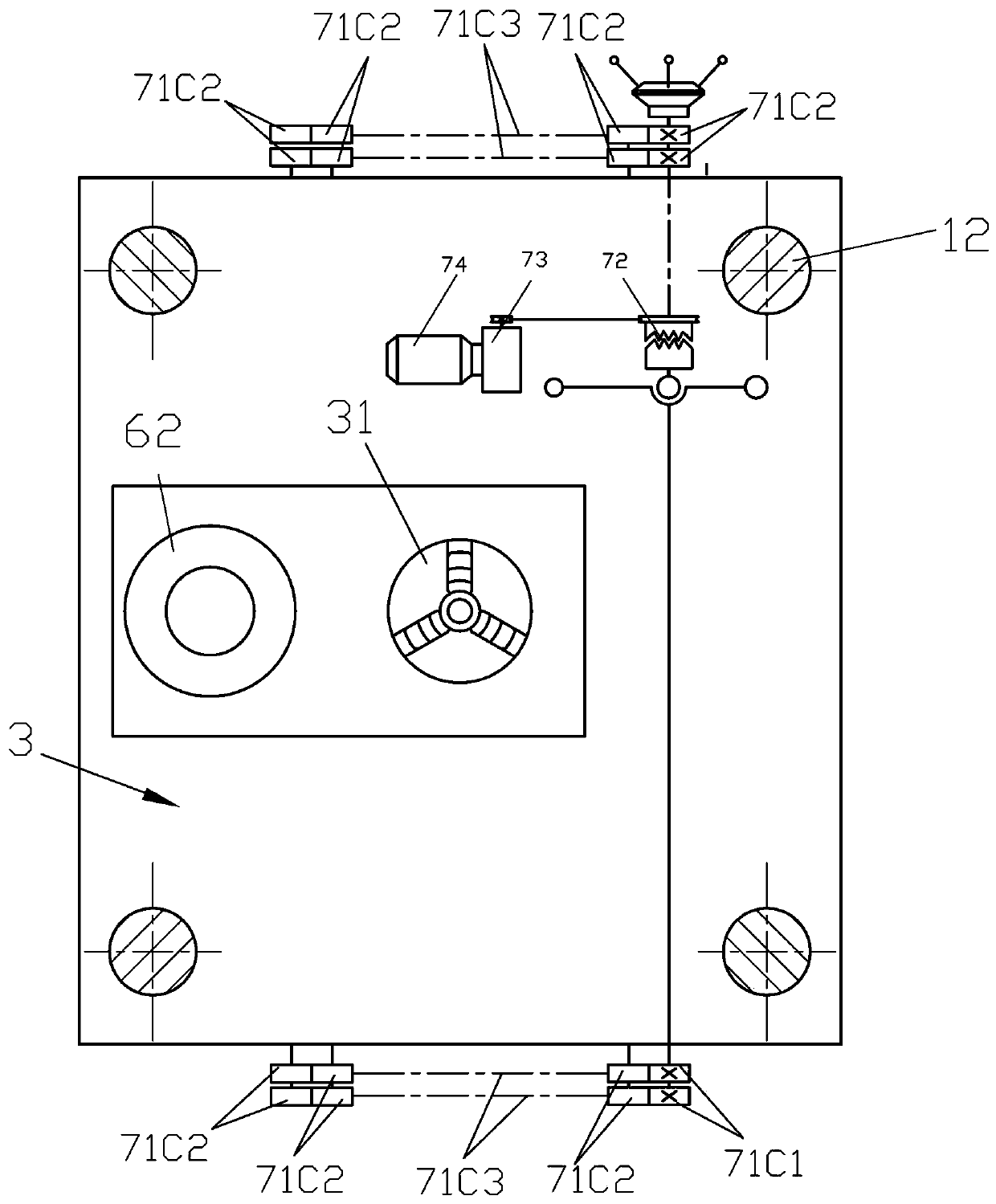

[0018] Such as Figure 1-3 As shown, a deep hole drilling rig comprises a derrick type fuselage 1, an inverted drilling tool assembly 2, a clamp assembly 3, a mandrel assembly 4, a transmission mechanism, and the fuselage 1 includes a guide rail 12, a fixed lower platform 11, a fixed The upper platform 13, the fixed workpiece platform 14, the drilling tool connection platform 15, the ejector rod connection platform 16, the inverted drilling tool assembly 2 is composed of the spindle seat 21 and the cutting tool 22, and the guide rail 12 of the fuselage 1 is also the supporting column. The tool connection platform 15 and the ejector rod connection platform 16 are planar bearing sliding platforms that move up and down along the guide rail 12. The fixture assembly 3 is composed of a workpiece fixture 31 and a drilling mold 32. The ejector rod assembly 4 is composed of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com