A kind of silicate-based multicolor long afterglow luminescent material and preparation method thereof

A long afterglow luminescence, silicate technology, applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problems of inconsistent afterglow brightness and decay rate, different physical and chemical properties of multi-substrates, influence of afterglow color, etc., and achieve long afterglow time , high afterglow brightness, simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Accurately weigh the raw material CaCO according to the molar ratio 3 (analytical pure), SiO 2 (analytical pure) and CeO 2 (analytical pure), the corresponding molar ratio is 3:2:0.01, and then weigh the H with a mass fraction of 10%. 3 BO 3 (analytical pure), grind and mix the weighed raw materials evenly, put them in a corundum crucible, then put them into a high-temperature tube furnace, keep them warm in the air at 1300°C for 6 hours, cool naturally to room temperature, and re- Grind evenly, then put it into a high-temperature tube furnace, keep it warm for 6 hours in a reducing atmosphere (the reducing atmosphere is a mixture of hydrogen and nitrogen, wherein the volume ratio of hydrogen and nitrogen is 10:90) at 1300 ° C, and finally cool naturally to At room temperature, grind again to obtain a solid powder product. After testing its luminescence spectrum, under the excitation of 325nm light, it produces a blue broadband emission. The sample showed a long bl...

Embodiment 2

[0037] Accurately weigh the raw material CaCO according to the molar ratio 3 (analytical pure), SiO 2 (analytical pure) and CeO 2(analytical pure), the corresponding molar ratio is 3:2:0.02, and then weigh the H with a mass fraction of 10%. 3 BO 3 (analytical pure), grind and mix the weighed raw materials evenly, put them in a corundum crucible, put them into a high-temperature tube furnace, keep them warm in the air at 1300°C for 6 hours, cool them naturally to room temperature, and re- Grind it evenly, then put it into a high-temperature tube furnace, keep it in a reducing atmosphere (the volume ratio of hydrogen to nitrogen is 5:95) at 1300°C for 8 hours, and finally cool it naturally to room temperature, and grind it again to obtain a solid powder product. After testing its luminescence spectrum, under the excitation of 325nm light, it produces a blue broadband emission. The sample showed a long blue afterglow after the 254nm UV excitation stopped.

Embodiment 3

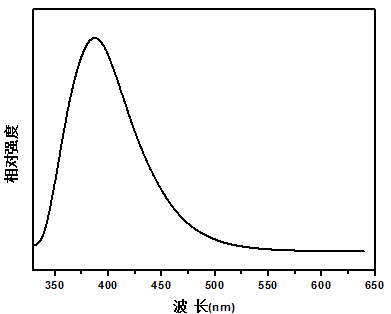

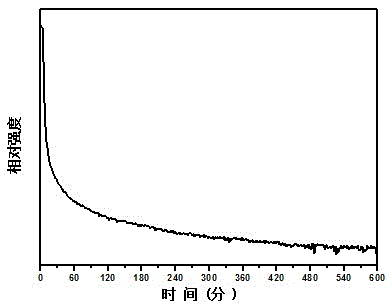

[0039] Accurately weigh the raw material CaCO according to the molar ratio 3 (analytical pure), SiO 2 (analytical pure) and CeO 2 (analytical pure), the corresponding molar ratio is 3:2:0.03, and then weigh the H with a mass fraction of 10%. 3 BO 3 (analytical pure), grind and mix the weighed raw materials evenly, put them in a corundum crucible, put them into a high-temperature tube furnace, keep them warm in the air at 1300°C for 6 hours, cool them naturally to room temperature, and re- Grind it evenly, then put it into a high-temperature tube furnace, keep it in a reducing atmosphere (the volume ratio of hydrogen to nitrogen is 8:92) at 1300°C for 6 hours, and finally cool it naturally to room temperature, and grind it again to obtain a solid powder product. After testing its luminescence spectrum, under the excitation of 325nm light, it produces a blue broadband emission, such as figure 1 shown. The sample showed a long blue afterglow after the 254nm UV excitation sto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com