A hot blast stove system and its corresponding combustion control method

A control method and technology for a hot blast stove, which are applied in the combustion method, controlled combustion, furnace and other directions, can solve the problems of low calorific value of pyrolysis gas, low temperature of the furnace chamber of the hot blast stove, and cannot meet the needs of large-flow gas combustion support.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

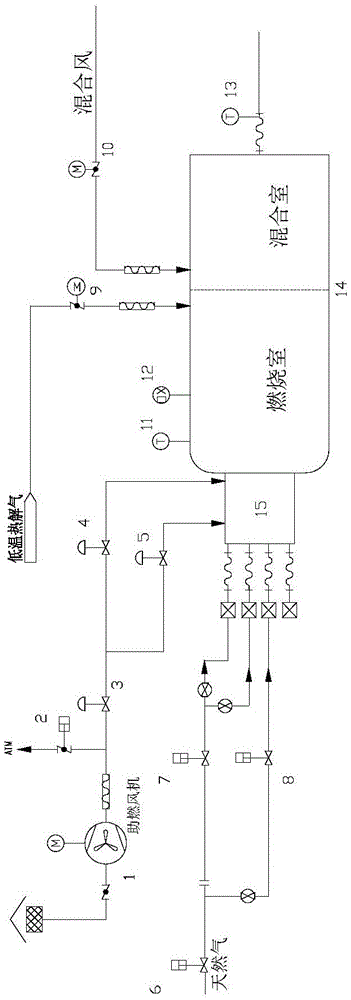

[0022] In order to better understand the purpose of the present invention, the hot blast stove system and its corresponding combustion control method and process described in the present invention will be described in detail below in combination with the background, drawings and actual working conditions.

[0023] The hot blast stove system of the present invention includes: a hot blast stove 14, a combustion-supporting fan 1, a burner 15, a plurality of dampers, a plurality of valves, and a plurality of measuring elements, and the hot blast stove 14 includes a combustion chamber separated by a partition and a mixing chamber, the burner 15 is arranged on the side of the combustion chamber, the combustion-supporting fan 1 operates with frequency conversion to precisely control the combustion-supporting air volume, and the pipeline between the combustion-supporting fan 1 and the burner 15 is provided with an exhaust valve 2. A quick-closing damper 3 is arranged between the exhaus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com