Cyclone combustion type energy-saving cooker

A technology of cyclone combustion and cooker, which is applied in the field of kitchen cooker, which can solve the problems of low utilization rate of combustion heat, small amount of air mixing, low combustion efficiency of gas, etc., achieve better heating effect, improve heating efficiency, and improve combustion efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

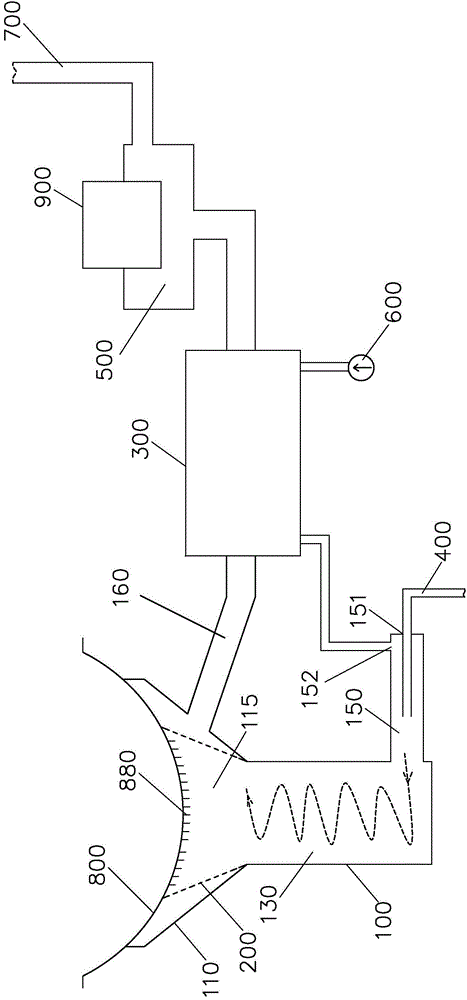

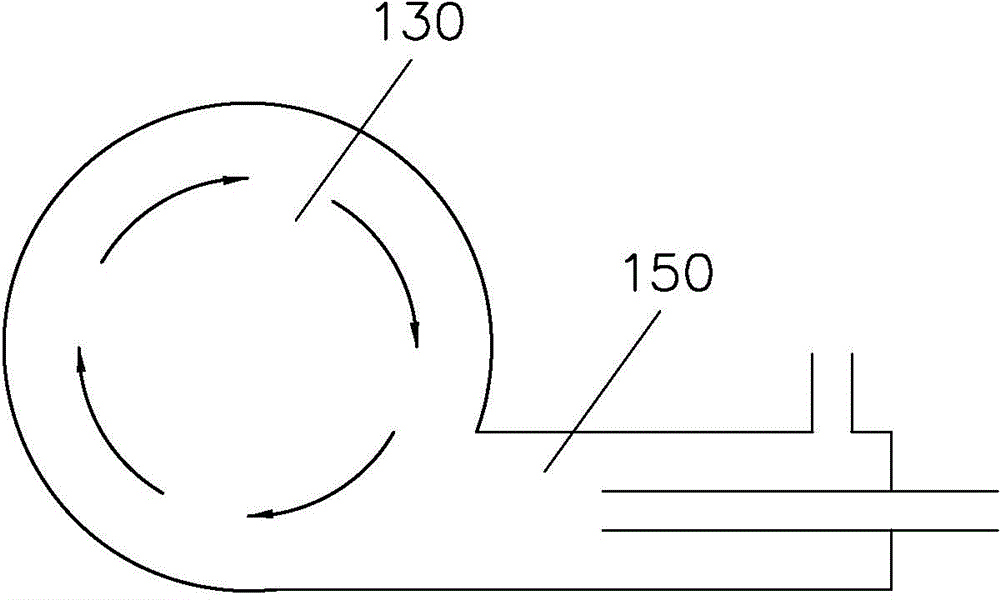

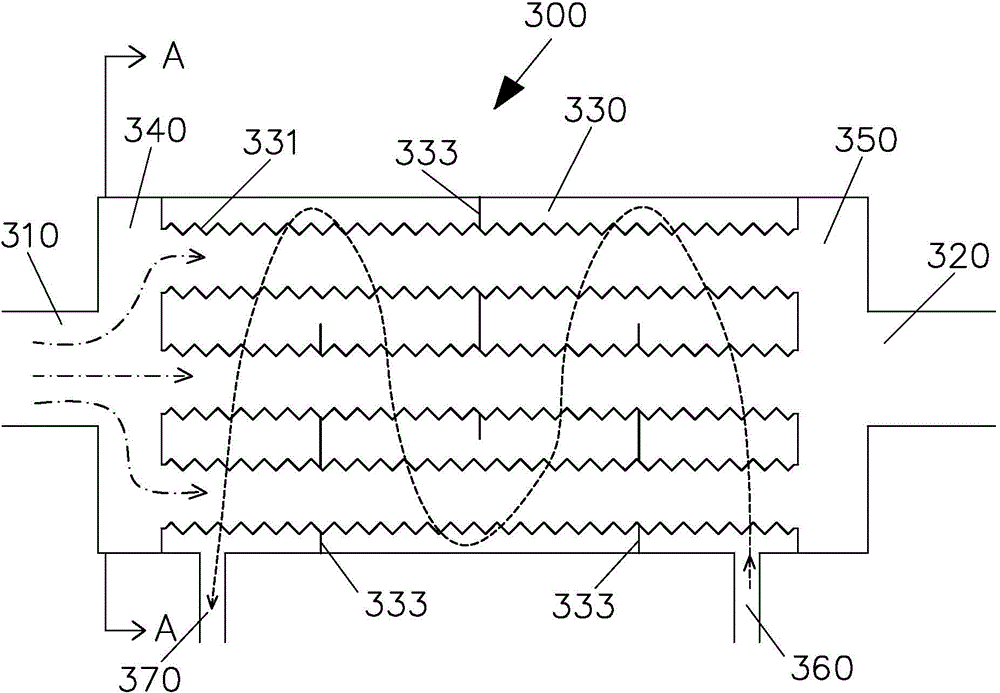

[0026] Please refer to Figure 1 to Figure 4 , as a non-limiting embodiment, the cyclone combustion energy-saving cooker of the present invention includes: a cooker 110, which is used to support a frying pan 800, and a flame chamber 115 is formed in the cooker 110; a swirl chamber 130, which is arranged under the cooker 110 And communicate with the flame chamber 115; premixing pipe 150, which is connected to the lower side wall of the swirl chamber 130, the premixing pipe 150 is provided with a passage hole 151 and an air inlet 152, and the fuel pipe 400 extends through the passage hole 151 to the premixing chamber. Tube 150 middle.

[0027] The swirl chamber 130 is cylindrical, the premixing pipe 150 is connected to the lower side wall of the swirl chamber 130 along the tangential direction of the peripheral wall of the swirl chamber 130, the air from the air inlet 152 and the fuel from the fuel pipe 400 ( In this embodiment, gas) is premixed in the premixing pipe 150 , the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com