Device for measuring four-freedom-degree kinematic errors of guide rail through non-diffraction light

A technology without diffracted light and motion errors, applied in the direction of measuring devices, optical devices, instruments, etc., can solve problems affecting measurement stability and accuracy, high price, complex lasers, etc., and achieve low cost, high-precision measurement, measurement wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to facilitate those of ordinary skill in the art to understand and implement the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the implementation examples described here are only used to illustrate and explain the present invention, and are not intended to limit this invention.

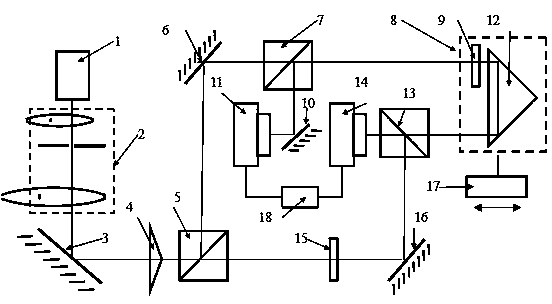

[0023] please see figure 1 , the technical solution adopted in the present invention is: a device for measuring the four-degree-of-freedom motion error of the guide rail by using non-diffraction light, which is characterized in that it includes a He-Ne laser 1, a collimating beam expander 2, and a first plane mirror 3 , axicon mirror 4, the first dichroic prism 5, the second plane mirror 6, the second dichroic prism 7, the mobile unit 8, the half-mirror 9, the third plane mirror 10, the first camera 11, the rectangular prism 12, the 3rd dichroic prism 13, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com