Graphene-CoS nanosheet composite counter electrode and preparation method thereof

A graphene and nanosheet technology, applied in circuits, capacitors, electrolytic capacitors, etc., can solve problems such as adverse effects on the structure and performance of thin film materials, it is difficult to obtain a rich morphology, a composite structure of electrical and catalytic properties, and the existence of the environment. Achieve the effect of improving photoelectric conversion efficiency, multiple electrochemical catalytic active sites, and enhancing catalytic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

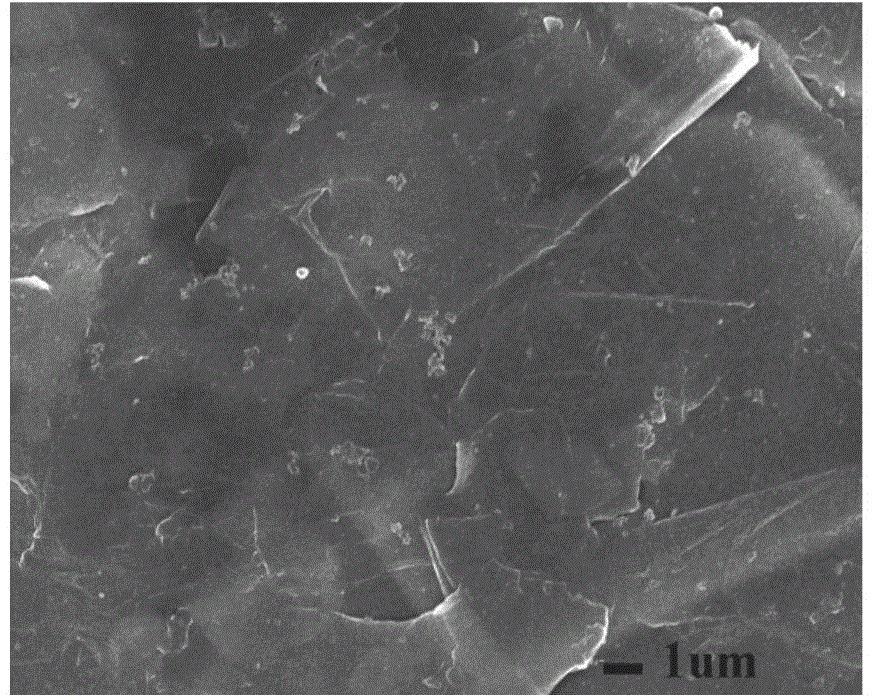

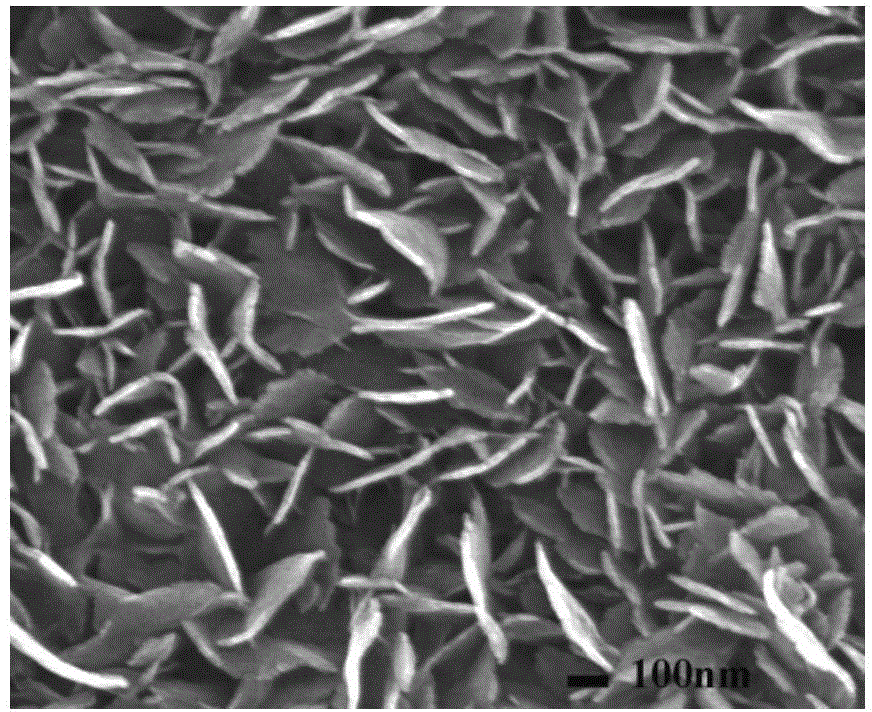

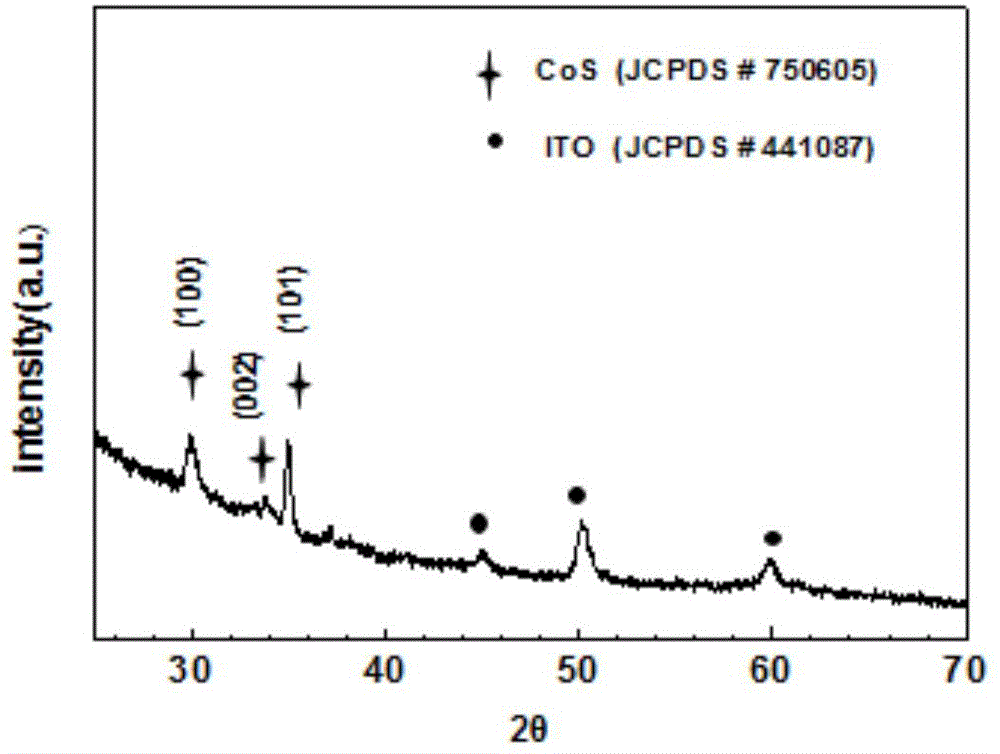

[0032] (1) preparation concentration is the GO ethanol solution of 10mg / L, deposits GO thin film on ITO conductive glass substrate by spraying process;

[0033] (2) preparation concentration is the CoCl of 5mM and the thiourea mixed aqueous solution that concentration is 15mM is electrolytic solution, and gained solution is denoted as A solution;

[0034] (3) Using solution A as the electrolyte, a three-electrode electrodeposition system was used to deposit CoS nanosheet arrays on the GO film at a constant potential; the temperature of the electrolyte was 25°C, the pH was 7, the deposition time was 5 min, and the deposition potential was -0.8V ;

[0035] (4) While the CoS nanosheet array is deposited at a constant potential, the graphene oxide is electrochemically reduced to graphene to form a graphene-CoS nanosheet composite film. After repeated washing with deionized water, place it in an oven and dry it for later use. .

Embodiment 2

[0037] (1) preparation concentration is the GO ethanol solution of 20mg / L, deposits GO thin film on ITO conductive glass substrate by spraying process;

[0038] (2) preparation concentration is the CoCl of 10mM and the thiourea mixed aqueous solution that concentration is 50mM is electrolytic solution, and gained solution is denoted as A solution;

[0039] (3) Using solution A as the electrolyte, a three-electrode electrodeposition system was used to deposit CoS nanosheet arrays on the GO film at a constant potential; the temperature of the electrolyte was 40 ° C, the pH was 10, the deposition time was 30 min, and the deposition potential was -0.8 V ;

[0040] (4) While the CoS nanosheet array is deposited at a constant potential, the graphene oxide is electrochemically reduced to graphene to form a graphene-CoS nanosheet composite film. After repeated washing with deionized water, place it in an oven and dry it for later use. .

Embodiment 3

[0042] (1) preparation concentration is the GO ethanol solution of 30mg / L, deposits GO thin film on ITO conductive glass substrate by spraying process;

[0043] (2) preparation concentration is the CoSO of 15mM and the thioacetamide mixed aqueous solution that concentration is 150mM is electrolytic solution, and the gained solution is denoted as A solution;

[0044] (3) Using solution A as the electrolyte, a three-electrode electrodeposition system was used to deposit CoS nanosheet arrays on the GO film at a constant potential; the temperature of the electrolyte was 50 ° C, the pH was 7, the deposition time was 20 min, and the deposition potential was -0.8 V ;

[0045] (4) While the CoS nanosheet array is deposited at a constant potential, the graphene oxide is electrochemically reduced to graphene to form a graphene-CoS nanosheet composite film. After repeated washing with deionized water, place it in an oven and dry it for later use. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com