Pressurizing and liquid-cooling thermal-instability inhibiting system for battery

A thermal instability and liquid cooling technology, applied in the field of lithium batteries, can solve problems such as reducing energy density, and achieve the effect of ensuring safety and suppressing thermal instability chain reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

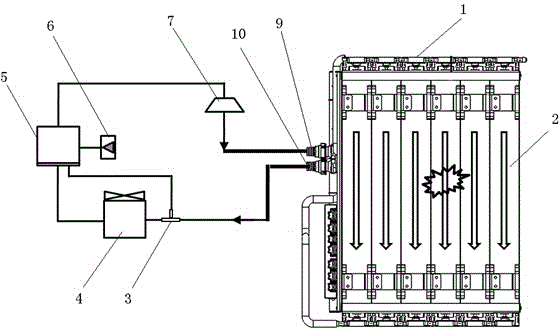

[0027] Such as figure 1 Shown is the first structure of this patent, a pressurized liquid cooling system to suppress battery thermal instability, including a liquid cooling system for cooling the battery in the battery box 1, the liquid cooling system includes a liquid storage tank 5. Liquid-cooled pump 7, air-cooled heat exchanger 4 and liquid pipes. The liquid pipes include connecting pipes arranged outside the battery box and cooling pipes 2 arranged between the batteries. The liquid storage tank 5 is connected with a A pressurizer 6, the pressurizer 6 pressurizes the cooling tube 2. The outlet end of the liquid storage tank 5 is connected to the liquid cooling pump 7, and the outlet end of the liquid cooling pump 7 is connected to the inlet end of the cooling pipe 2 arranged between the batteries through the first joint 9; The outlet end is connected to the inlet end of the air-cooled heat exchanger 4 through the second joint 10, and the outlet end of the air-cooled heat ...

Embodiment 2

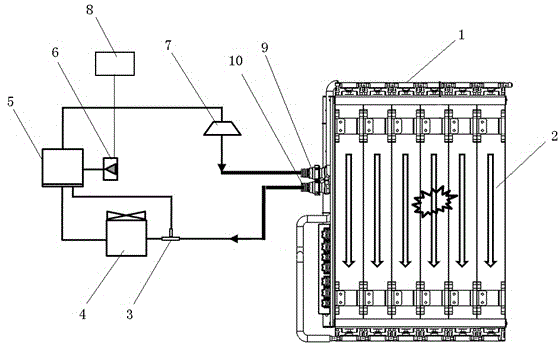

[0032] Such as figure 2 Shown is the second structure of this patent, which is different from the first structure in that the pressurizer 6 and the battery management system BMS 8 installed in the battery box for monitoring battery charge, discharge and temperature pass through The cable is connected, and the pressurizer 6 increases the pressure of the liquid cooling system through the temperature fed back by the battery management system BMS 8, so that the cooling pipe explodes in time.

[0033] That is, when a local battery generates thermal instability, a large amount of heat will be released in a relatively short period of time, which will eventually lead to a huge difference in the temperature at both ends of the liquid cooling tube entering and leaving the battery module. When the battery management system BMS 8 monitors that the temperature is abnormal, it starts the pressurizer 6 to pressurize the liquid in the liquid pipe. At this time, the cooling pipe 2 is deforme...

Embodiment 3

[0036]In this embodiment, an 18650 lithium battery pack is used as an example for illustration. The lithium battery pack weighs about 45 g and has 6 identical single cells in total. The comprehensive specific heat capacity of the battery pack has been measured to be about 1000J / kg℃, and the total energy of a single battery 3.7V 2.2AH is about 26640J; while the specific heat capacity of the liquid in the liquid cooling system is usually 1000-3000J / kg℃, the highest temperature of the battery system under normal use The temperature is 65°C, and the thermal instability temperature of the battery is 135°C.

[0037] When the thermal instability of a single battery occurs, all the energy is converted into heat, which will cause the temperature to rise by about 102°C. At this time, the average temperature of its adjacent batteries can reach a maximum of 65+102=167°C. Because there is a certain temperature difference in the battery itself, the local temperature of the single battery co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com