Electrolytic manganese waste water ion exchange treatment system under automatic control in whole process and adopting aeration type ion exchange device

An ion exchange device and ion exchange technology are applied in the field of electrolytic manganese wastewater ion exchange treatment system, which can solve the problems of ineffective loosening of the resin bed, increased head loss, unbalanced resin working state, etc., so as to improve the service cycle and use Efficiency, improved system operation efficiency, and easy-to-operate control methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

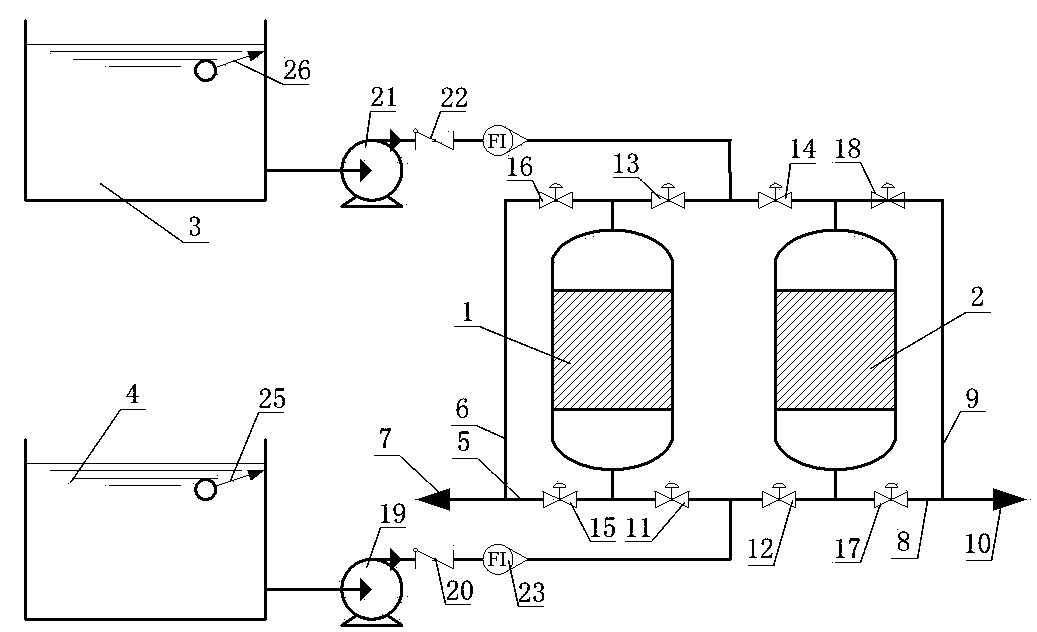

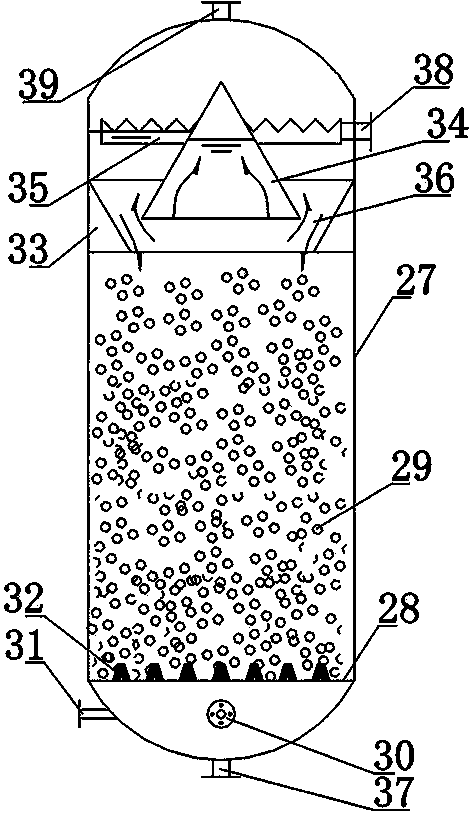

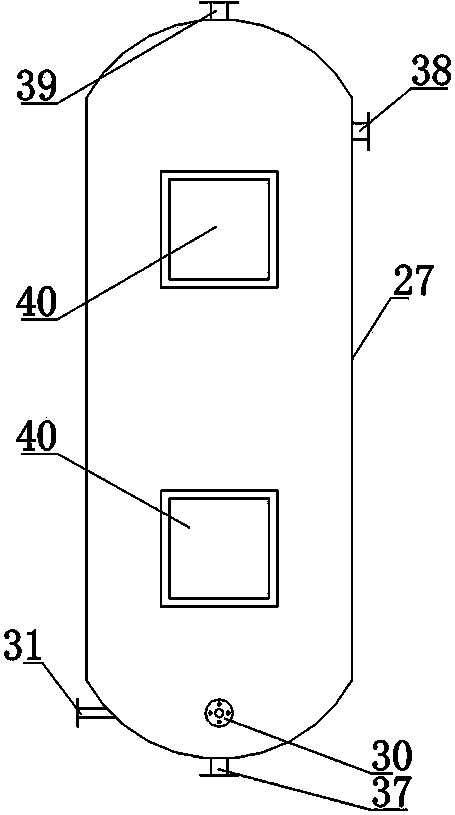

[0020] Such as figure 1 As shown, an electrolytic manganese wastewater ion exchange treatment system with automatic control of the whole process and an aeration ion exchange device includes ion exchanger A1, ion exchanger B2, regeneration liquid distribution tank 3, wastewater storage tank 4 and PLC The controller, the water outlet of the waste water storage tank 4 is respectively connected to the lower liquid inlet and outlet of the ion exchanger A1 and the lower liquid inlet and outlet of the ion exchanger B2 through pipelines, and the water outlet of the waste water storage tank 4 is connected to the water outlet of the ion exchanger A1 An electric valve A11 is installed on the pipeline of the lower liquid inlet and outlet, and an electric valve B12 is installed on the pipeline connecting the wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com