A kind of ultra-thin road surface sealing layer treatment material and preparation method thereof

A road surface and ultra-thin technology, which is applied in the field of new ultra-thin road surface sealant treatment materials and its preparation, can solve the problems of high-grade asphalt pavement preventive maintenance effect is not obvious, the appearance color is not uniform, and the driving noise is loud. , to achieve the effect of easy on-site quality control, improved anti-damage performance, and low driving noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

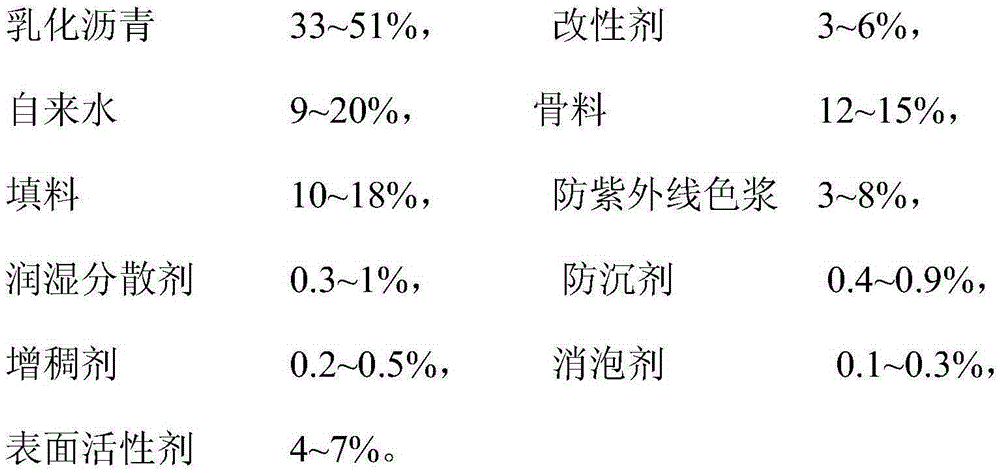

[0040] Weigh each component according to the following formula: 35% emulsified asphalt; 3% modifier; 20% tap water; 12% aggregate; 15% filler; 6% anti-ultraviolet color paste; 0.5% wetting and dispersing agent; 0.9%; thickener 0.5%; defoamer 0.1%; surfactant 7%;

[0041] The preparation method of embodiment 1 is:

[0042] a. Under stirring conditions, disperse the wetting and dispersing agent in tap water, and add 20-30% of the weight of the defoamer, stir evenly, and add anti-settling agent and color paste under stirring at 800-1200r / min, Then stir and disperse until the fineness reaches below 60 μm, add the remaining defoamer under stirring conditions, stir and defoam for 3-5 minutes, and prepare the pigment slurry;

[0043] b. Under stirring conditions, add the modifier to the emulsified asphalt, stir at 800-1200r / min for 10-15min, then add the pigment slurry prepared in step a, add aggregate and filler, and stir for 30-40min , add surfactant and thickener, stir evenly, a...

Embodiment 2

[0045] Weigh each component according to the formula quantity, emulsified asphalt 40%; modifier 5%; tap water 13%; aggregate 12%; filler 18%; anti-ultraviolet color paste 6%; 0.7%; Thickener 0.5%; Defoamer 0.2%; Surfactant 4%.

[0046] The preparation method of embodiment 2 is the same as embodiment 1, and the stirring speed is 1000r / min.

Embodiment 3

[0048] Weigh each component according to the formula quantity, emulsified asphalt 48%; modifier 6%; tap water 9%; aggregate 12%; filler 10%; anti-ultraviolet color paste 8%; 0.8%; Thickener 0.4%; Defoamer 0.2%; Surfactant 5%.

[0049] The preparation method of embodiment 3 is the same as the preparation method of embodiment 1, and the stirring speed is 1000r / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com