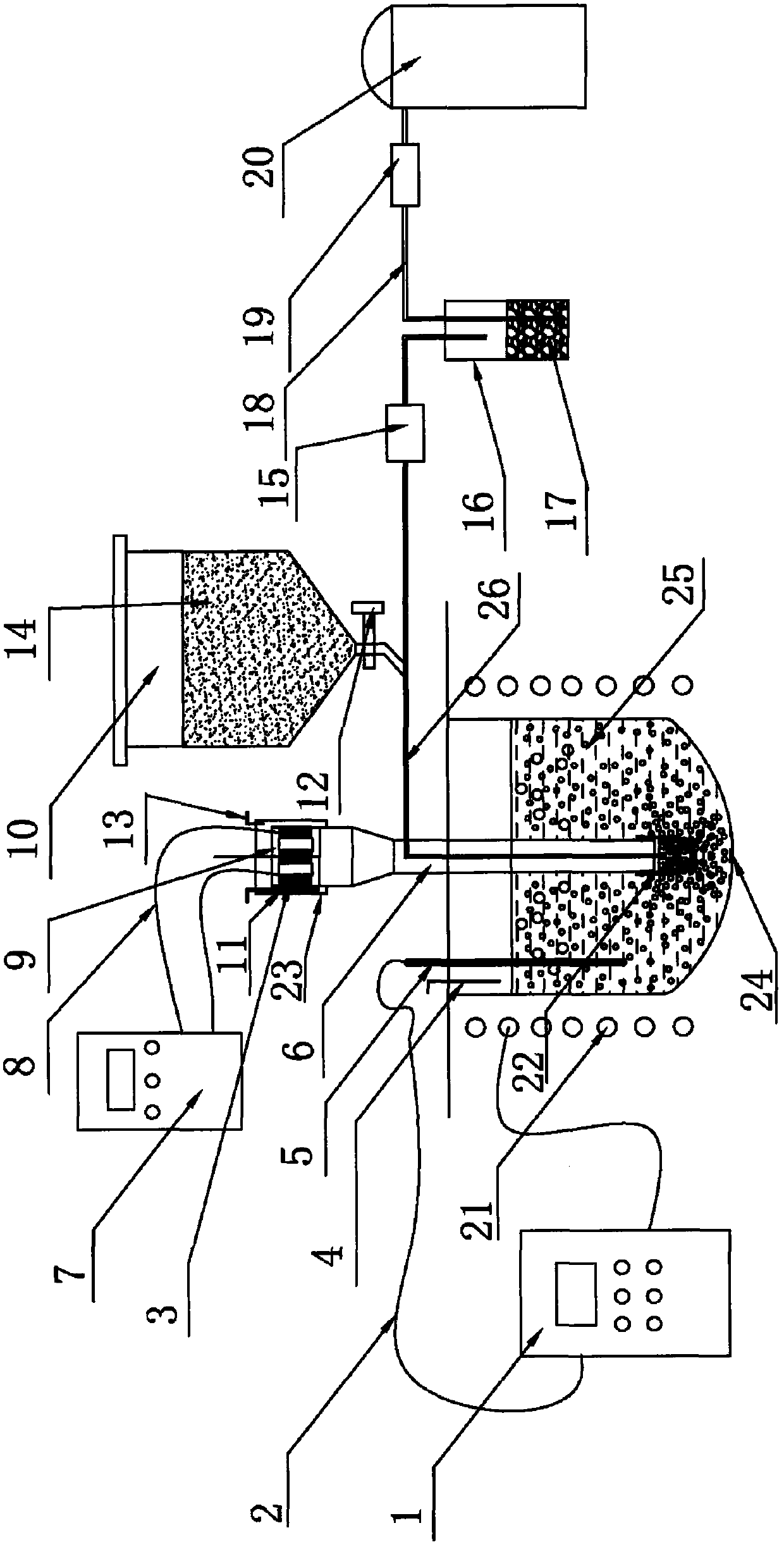

Magnesium alloy melt refining device

A refining device and technology for magnesium alloys, applied in the field of metal materials and metallurgy, can solve the problems of large bubble size, fast floating speed, large flux amount, etc., and achieve the effects of preventing oxidative combustion, reducing the moving speed and increasing the diffusion area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

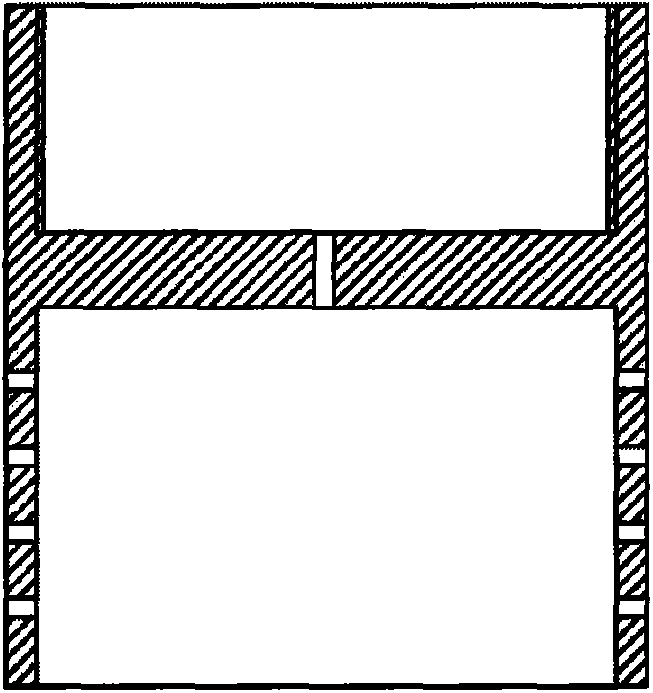

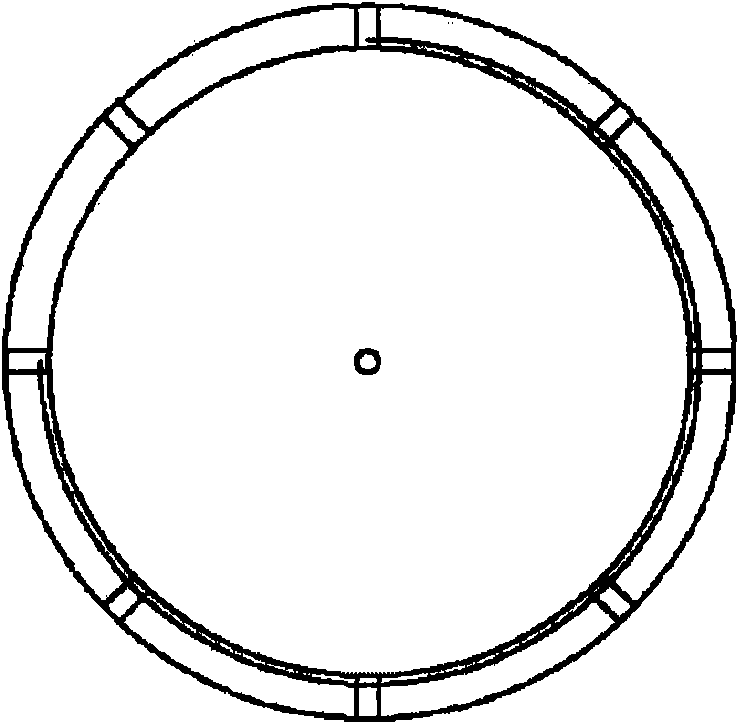

[0024] Utilize the device of the present invention to carry out purifying treatment to common commercial AZ91 magnesium alloy melt, the tool head structure in the device is as follows figure 2 As shown, the hole with a diameter of 0.7 mm is opened on the lower end wall of the tool head 22, and the number of holes on the wall is 10; the diameter of the air outlet on the end face of the tool head is 0.8 mm, and the number is 4; Medium melting, the melting temperature is 720°C. The tool head of the device of the invention was preheated to 720°C prior to processing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com