Polyester basic dyeing integrated auxiliary agent and application thereof

An integrated and additive technology, applied in the field of polyester fiber dyeing additives, can solve the problems of poor heat and alkali resistance, decreased color fastness to staining, decreased color fastness to rubbing, etc., to achieve soft hand feeling, good dyeing effect and The effect of feeling and avoiding the reduction of color fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

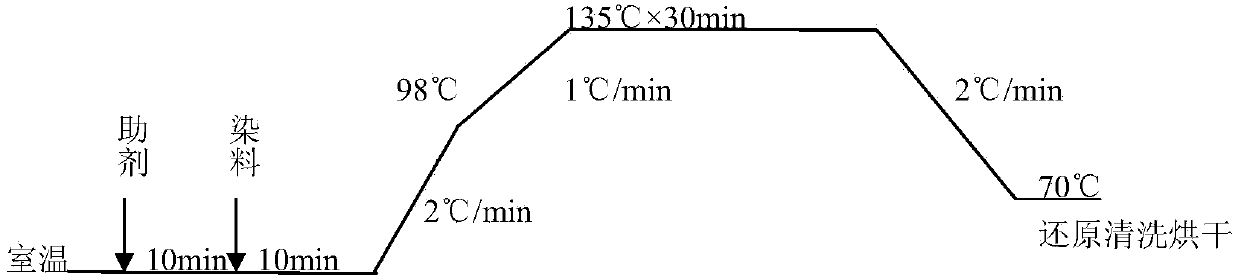

Method used

Image

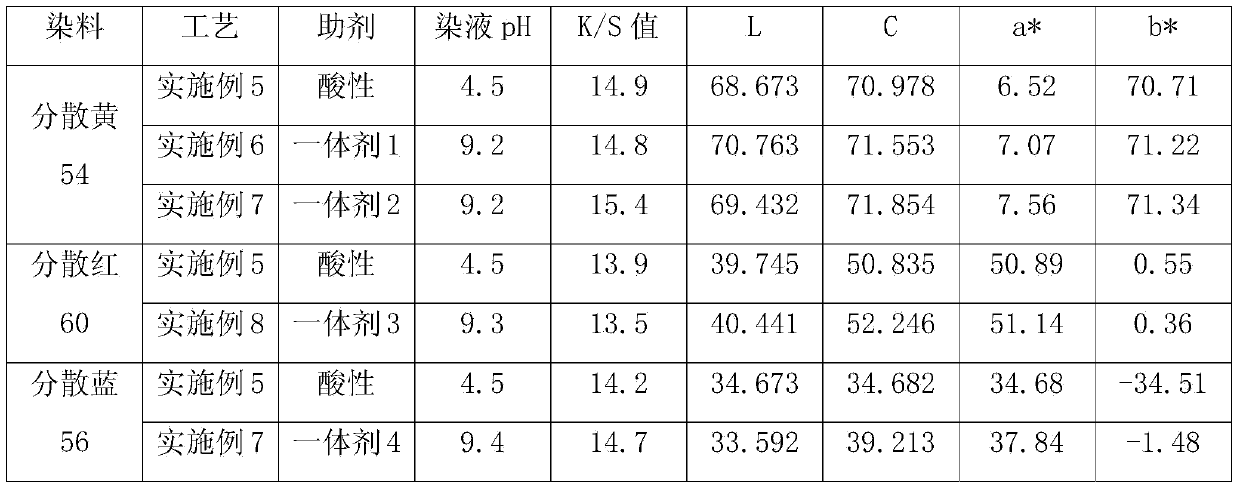

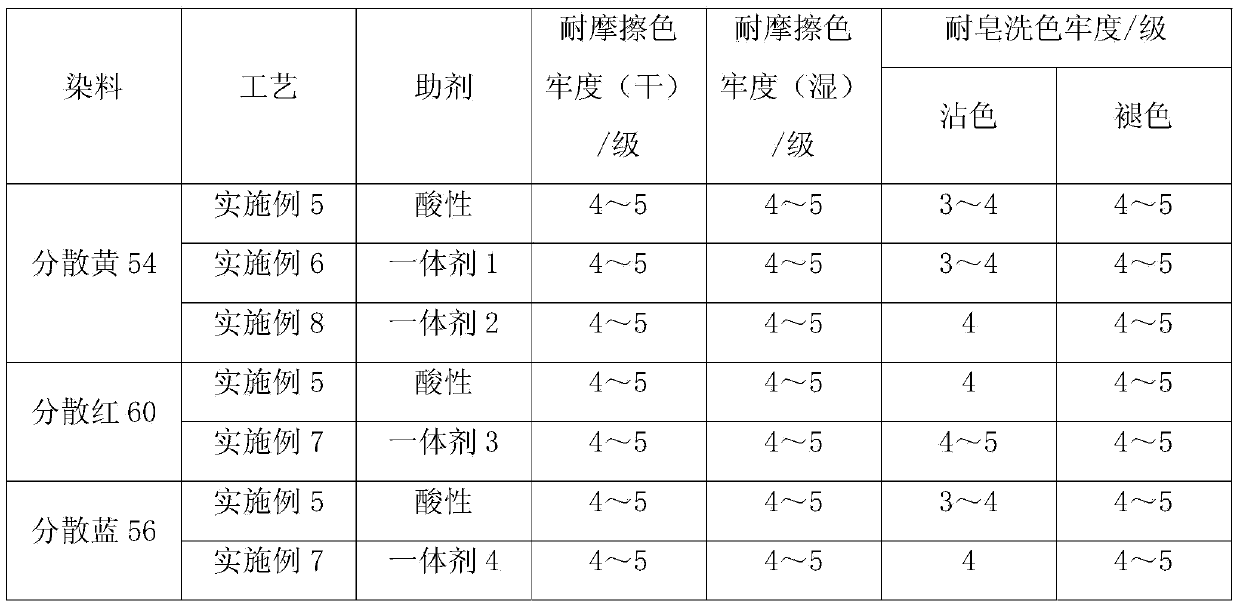

Examples

Embodiment 1

[0023] Embodiment 1 (basic dyeing agent 1)

[0024] Each component is calculated as:

[0025] Disodium ethylenediaminetetraacetic acid (EDTA-2Na) 20%

[0026] Trishydroxymethylaminomethane 16%

[0027] 2-Amino-2-methyl-1,3-propanediol 4%

[0028] Sodium dihydrogen phosphate 10%

[0029] Tween 80 2%

[0030] NNO 30%

[0031] The rest is water.

Embodiment 2

[0032] Embodiment 2 (basic dyeing agent 2)

[0033] Each component is calculated as:

[0034] Disodium ethylenediaminetetraacetic acid (EDTA-2Na) 24%

[0035] Trishydroxymethylaminomethane 12%

[0036] 2-Amino-2-methyl-1,3-propanediol 6%

[0037] N,N-Dimethylglycine 10%

[0038] Sodium dihydrogen phosphate 13%

[0039] Tween 80 8%

[0040] NNO 26%

[0041] The rest is water.

Embodiment 3

[0042] Embodiment 3 (basic chromogen 3)

[0043] Each component is calculated as:

[0044] Disodium ethylenediaminetetraacetic acid (EDTA-2Na) 30%

[0045] Trishydroxymethylaminomethane 14%

[0046] 2-Amino-2-methyl-1,3-propanediol 10%

[0047] N,N-Dimethylglycine 7%

[0048] Sodium dihydrogen phosphate 5%

[0049] Tween 80 5%

[0050] NNO 25%

[0051] The rest is water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com