Controlled grouting anti-skid composite structure of steel flower tube and its rapid construction method

A composite structure and steel flower tube technology, which is applied in basic structure engineering, excavation, construction, etc., can solve the problems of difficulty in realizing rapid mechanized construction of anti-sliding piles and insufficient anti-sliding ability, and achieve improved bending resistance, rapid construction, and convenient construction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

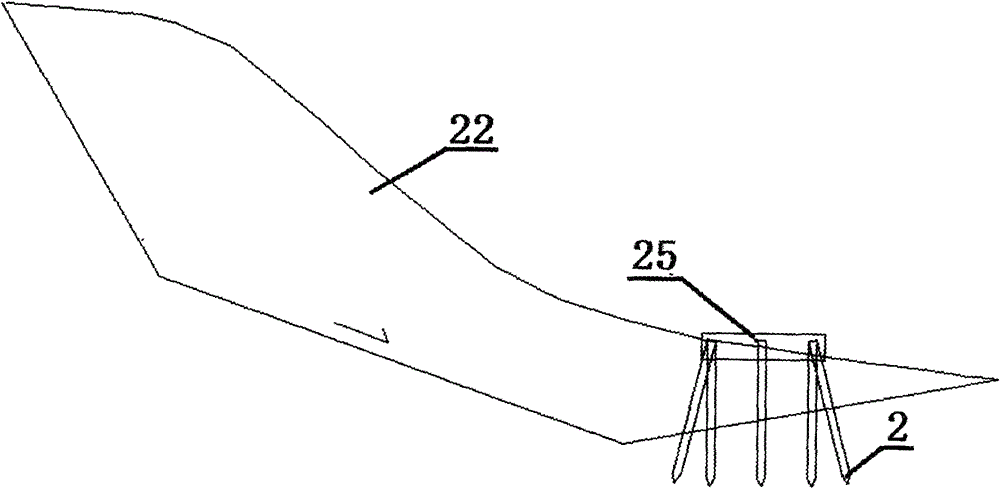

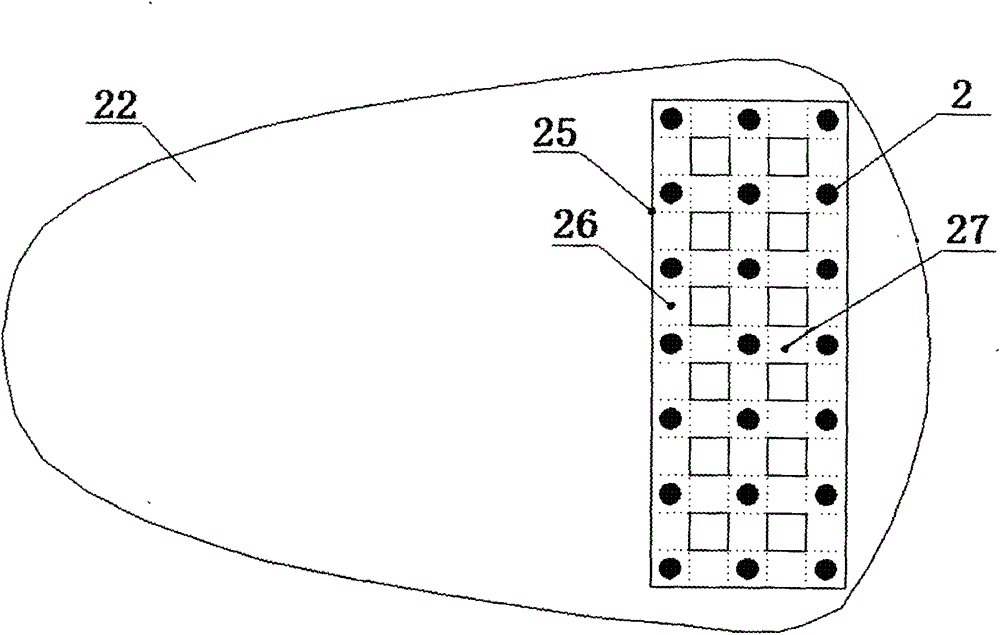

[0038] see Figure 1 to Figure 11 , the present invention is a kind of anti-sliding composite structure of steel flower pipe controlled grouting, comprising steel flower pipe piles, composite soil between piles and pipe top frame 25, and pipe top frame 25 is made of grid-like reinforced concrete beams 26 and longitudinal beams 27 Composition, fixed on the slope platform or embedded in the slope body 22. The top of the steel flower pipe pile and the pipe roof frame are poured together; the composite soil between the steel flower pipe piles is formed by splitting grouting; the steel flower pipe pile, the composite soil between the piles and the pipe roof frame 25 form a composite structure to jointly resist landslides thrust or earth pressure.

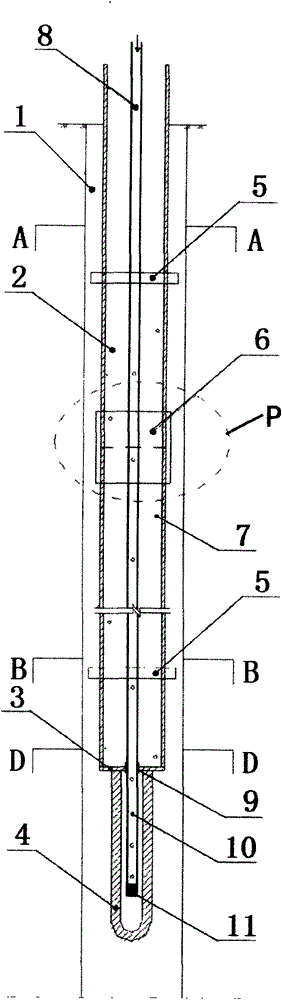

[0039] The steel flower pipe pile includes a steel flower pipe 2 and a primary grouting pipe 8, and a plurality of axially spaced centering rings 5 are installed on the steel flower pipe 2, which are used to position the steel flower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com