Light two-component soft thin layer local resonance acoustic material structure

A technology of local resonance acoustics and material structure, which is applied in the direction of sound-emitting devices and instruments, can solve the problems of large space occupation, noise amplification, and lack of sound insulation effect, etc., and achieve the effect of simple design, easy processing and manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] (1) The same light and flexible material as the elastic element and mass element

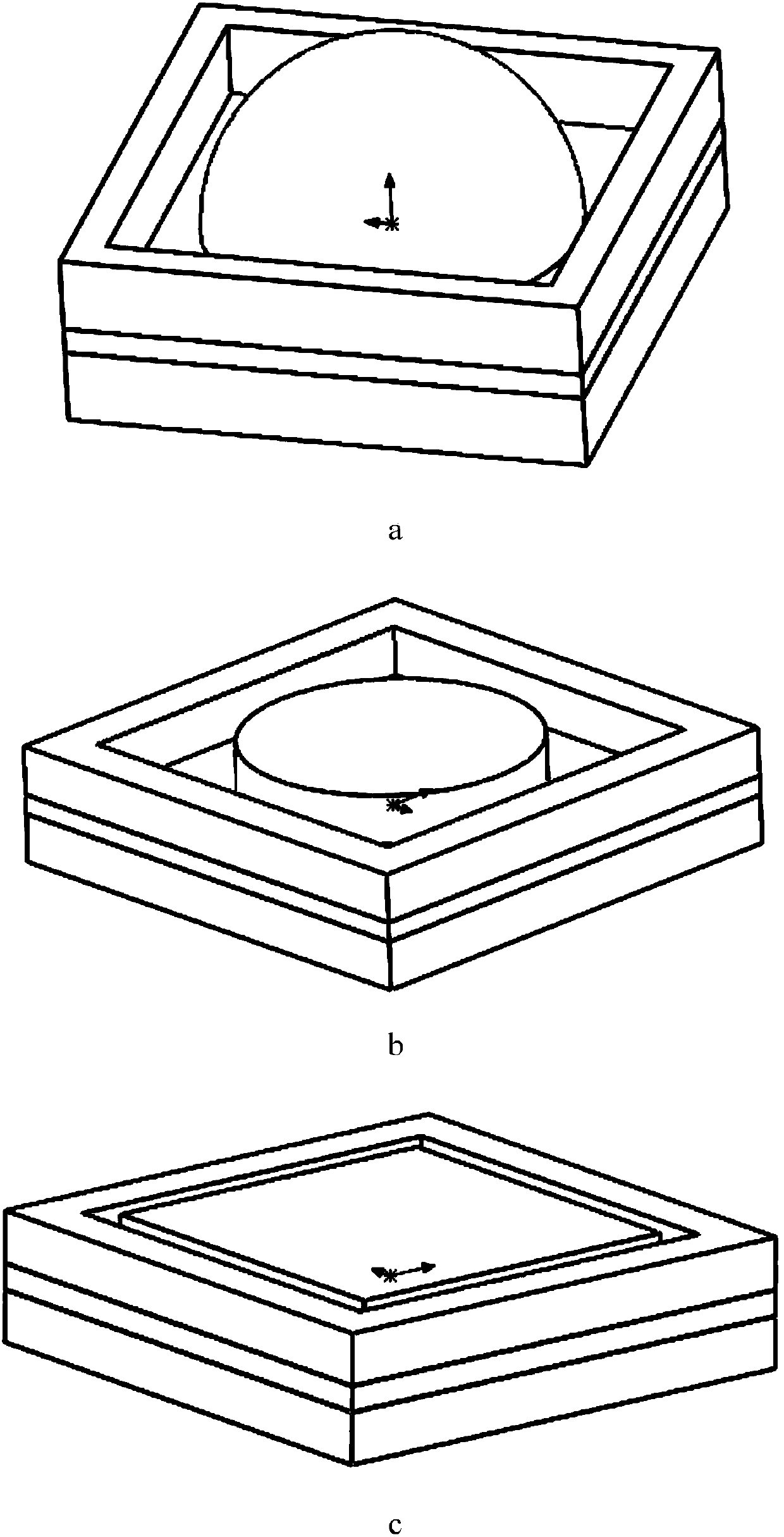

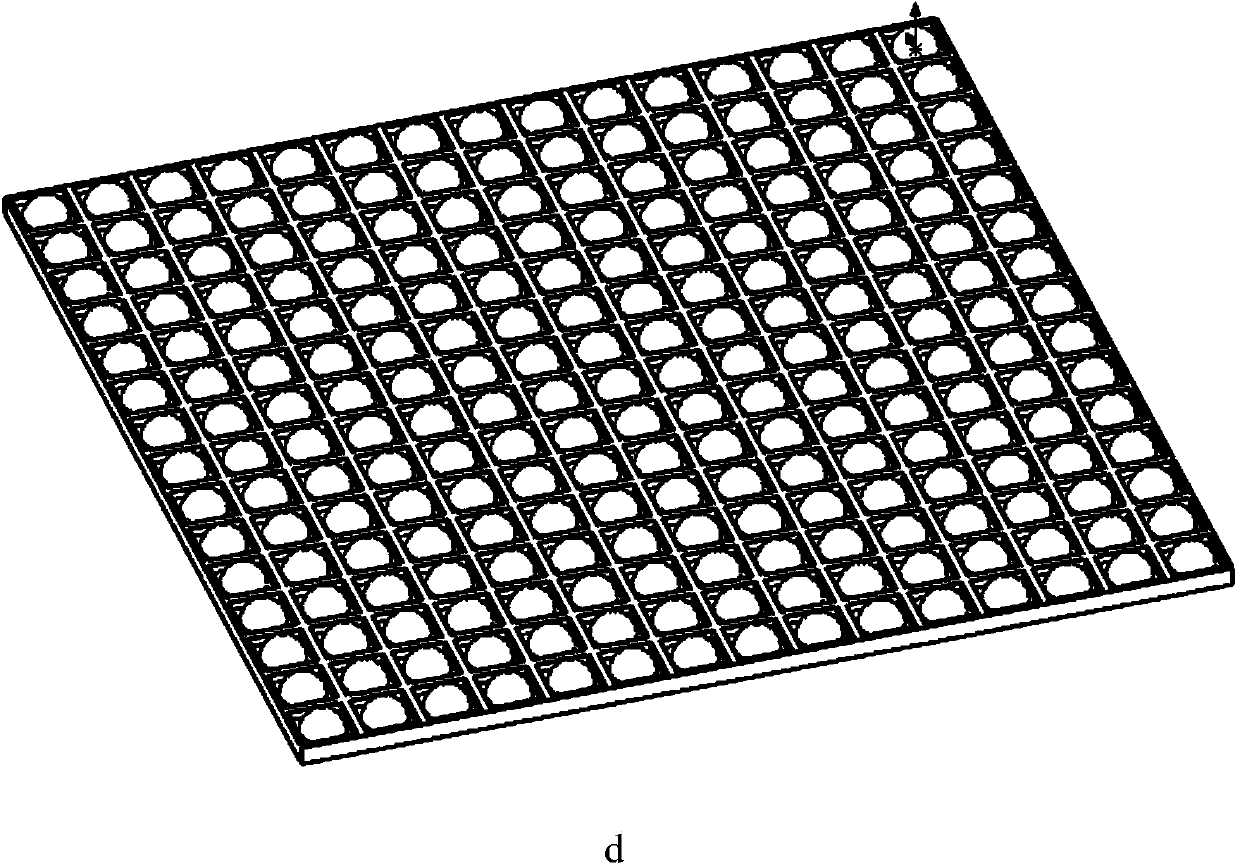

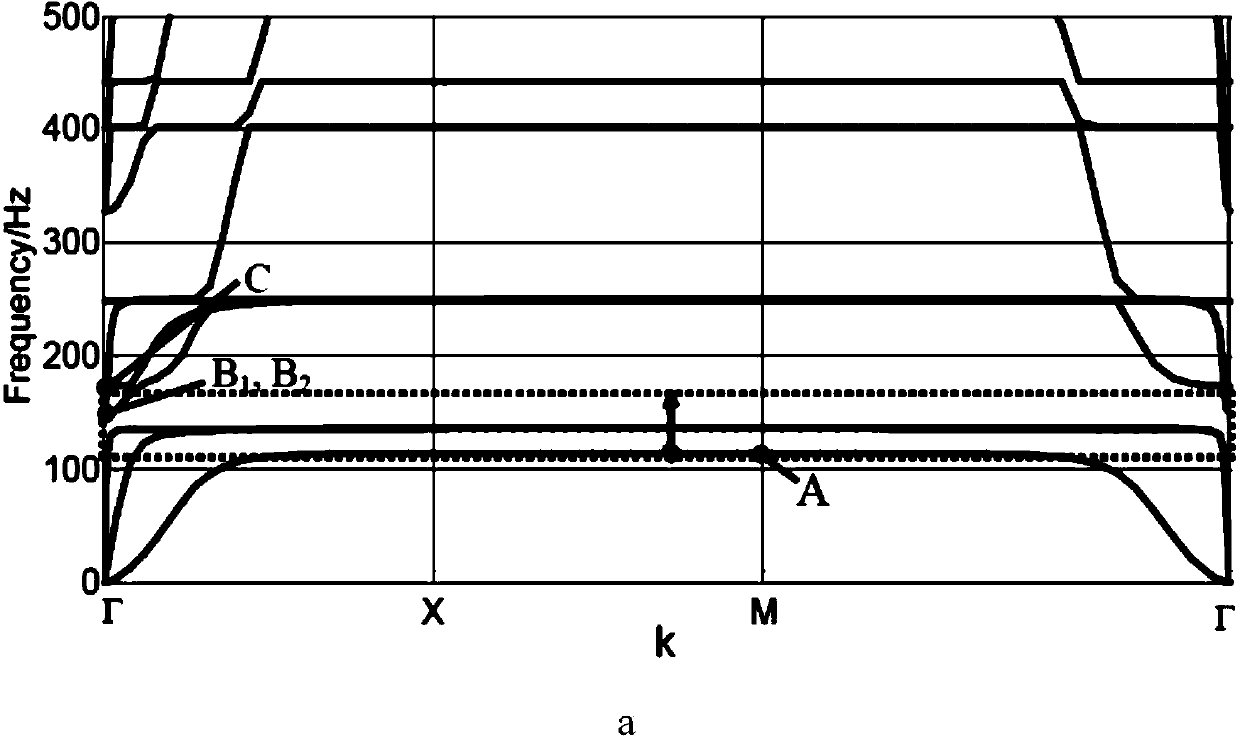

[0034] The present invention uses silicon rubber with good elasticity as the elastic element and mass element, and the elastic element is designed as a film type, that is, a silicon rubber film with a thickness of no more than 1mm; the quality block is designed to be hemispherical, cylindrical, or square. Among them, the radius of the hemisphere does not exceed 5mm, and the thickness of the cylinder and the box does not exceed 2mm. For the convenience of illustration, several shapes of two-component local resonance units are designed, and the cell structure is as follows figure 1 shown. Each cell consists of 3 parts, mass block, film and frame. Both the quality block and the film are made of flexible silicone rubber, and the frame is made of plastic with better toughness or softer EVA (EVA (ethylene-vinyl acetate copolymer, ethylene-vinyl acetate copolymer). The quality block is divided...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com