Metallized capacitor film with improved oxidation resistance

A technology of metallized capacitors and anti-oxidation performance, which is applied in the direction of fixed capacitor electrodes and parts of fixed capacitors, and can solve the problems of rapid decline in capacitor capacity, difficult handling, and capacitor heating.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The content of the present invention will be described below in conjunction with specific embodiments.

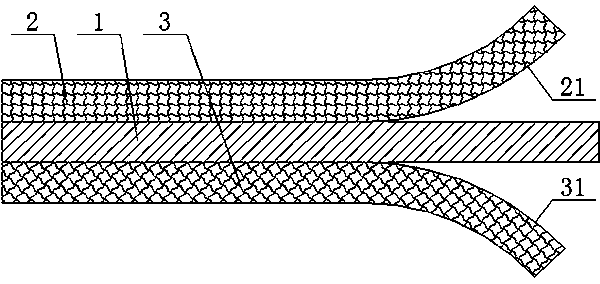

[0021] Such as figure 1 Shown is a schematic structural diagram of a metallized capacitor film with improved oxidation resistance according to the present invention. A metallized capacitor film with improved oxidation resistance according to the present invention comprises: a metal coating 1 and a plastic film top layer 2 and a plastic film bottom layer 3 respectively located on both sides of the metal coating, and the material of the metal coating 1 is zinc and / or aluminum , the material of the plastic film top layer 2 and the plastic film bottom layer 3 is polyolefin;

[0022] The plastic film top layer 2 has a contact bottom surface 21 in contact with the metal coating 1, the plastic film bottom layer 3 has a contact top surface 31 in contact with the metal coating 1, the contact bottom surface 21 and the contact top surface 31 have the same surface charge densi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com