Metal Al monocrystal film growing on sapphire substrate and preparing method and application of metal Al monocrystal film

A sapphire substrate and single crystal thin film technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of poor performance such as the purity of metal Al thin films, crystal quality and surface flatness, and achieve repeatability , easy access, high crystal quality results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

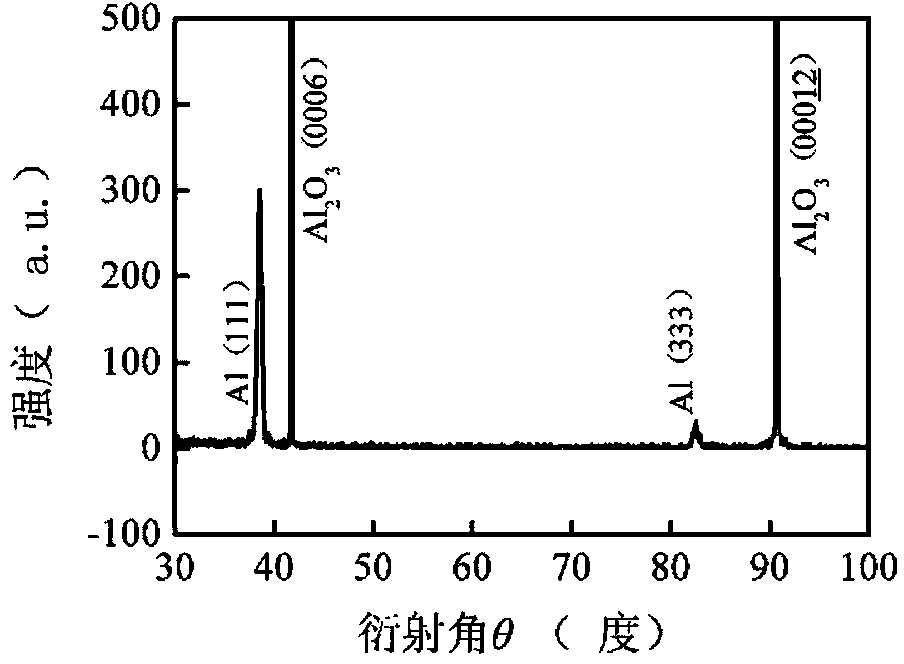

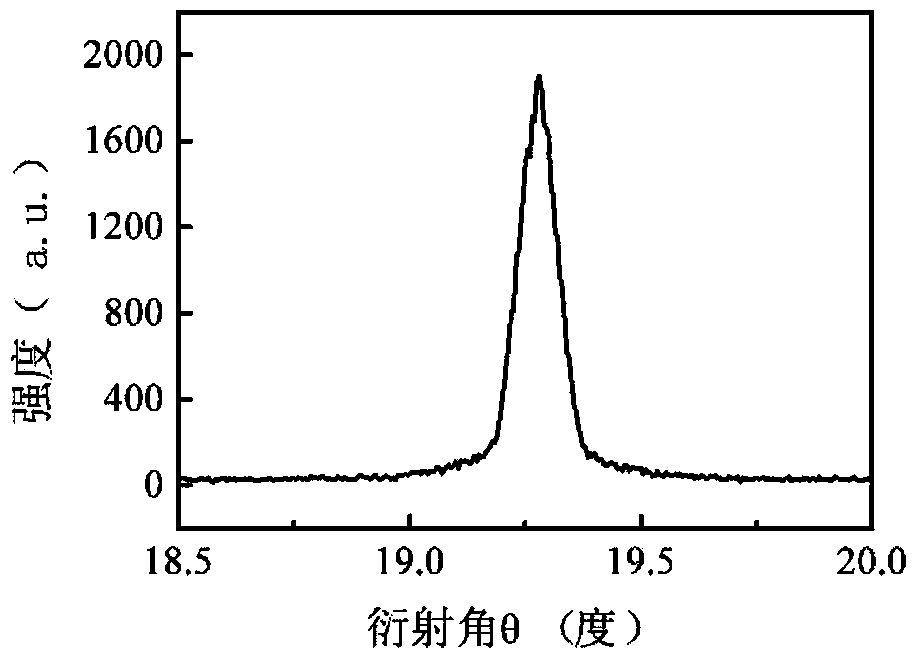

[0033] A metal Al single crystal film grown on a sapphire substrate, including Al 2 o 3 The substrate 11 and the metal Al single crystal thin film 12 grown in the direction of the epitaxial direction (0002) to the (10-12) plane by 0.2°. The thickness of the metal Al single crystal thin film is 350nm.

[0034] The metal Al single crystal film grown on the sapphire substrate is prepared by the following steps:

[0035] a. Al 2 o 3 The substrate is cleaned and annealed; the specific process of the annealing is: the substrate is placed in the annealing chamber, and the Al 2 o 3 The substrate is annealed for 60 minutes and then cooled to room temperature in air; the cleaning is specifically: Al 2 o 3 Substrates were placed in deionized water and then ultrasonically cleaned at room temperature for 3 minutes to remove Al 2 o 3 The dirt particles on the surface of the substrate are washed with hydrochloric acid, acetone, and ethanol in sequence to remove surface organic matte...

Embodiment 2

[0043] A metal Al single crystal thin film grown on a sapphire substrate comprises an Al2O3 substrate and a metal Al single crystal thin film whose (0002) plane deviates 0.4° to the (10-12) direction for epitaxial growth. The thickness of the metal Al single crystal thin film is 420nm.

[0044] The metal Al single crystal film grown on the sapphire substrate is prepared by the following steps:

[0045] a. Clean and anneal the Al2O3 substrate; the specific process of the annealing is: put the substrate into the annealing chamber, and treat the Al2O3 substrate in an air atmosphere at 870°C 2 o 3 The substrate is annealed for 60 minutes and then cooled to room temperature in air; the cleaning is specifically: Al 2 o 3 The substrate was placed in deionized water, and then ultrasonically cleaned at room temperature for 3 minutes to remove Al 2 o 3 The dirt particles on the surface of the substrate are washed with hydrochloric acid, acetone, and ethanol in sequence to remove su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com