Methods to decontaminate cereal grains with chlorine dioxide

A chlorine dioxide, grain technology, applied in the direction of biochemical equipment and methods, preservation of seeds with chemicals, application, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

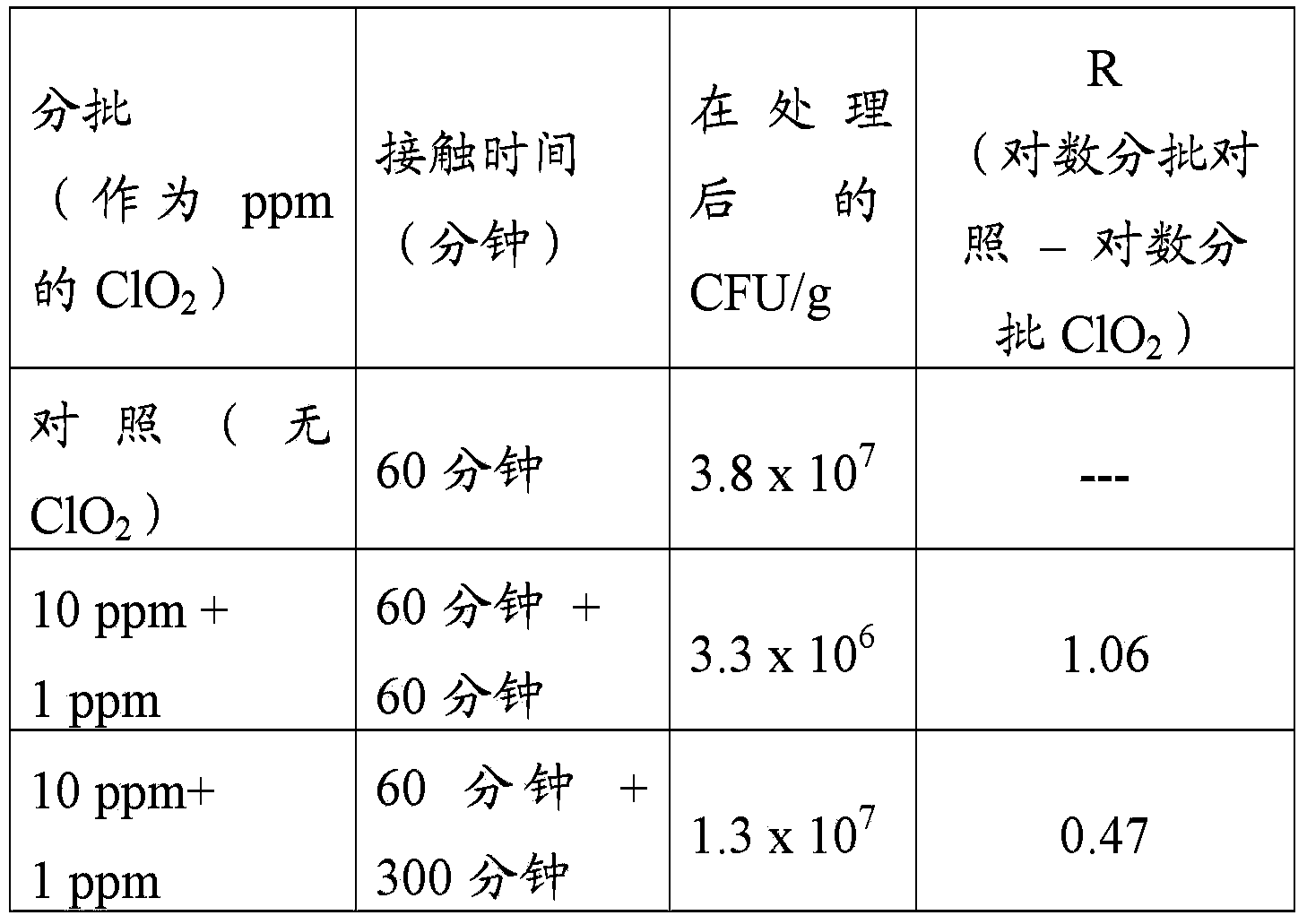

[0059] Example 1: Treatment of Barley with Chlorine Dioxide (Artificial Contamination by Fusarium)

[0060] Investigation of the performance of chlorine dioxide in reducing initial Fusarium load on barley. Barley samples were artificially contaminated with Fusarium cells by spraying and drying before treatment with chlorine dioxide.

[0061] method. The chlorine dioxide solution was generated using Diversey's ClearKlens Bi-Spore Set (base VH26 and activator VH26). Prepare fresh stock solutions according to product instructions. Use Dr. Lange test kit (LCK310 / 343) and photometer DR2800 device to measure the concentration of chlorine dioxide in the stock solution and the use solution. With the help of CEN hard water diluent (300mg / kg CaCO 3 ) to prepare the chlorine dioxide use solution by diluting the Bi-Spore stock solution. The neutralizing solution was based on sodium thiosulfate (5 g / L in 1 / 4 strength Ringer's solution). The experiments were carried out on the basis o...

example 2

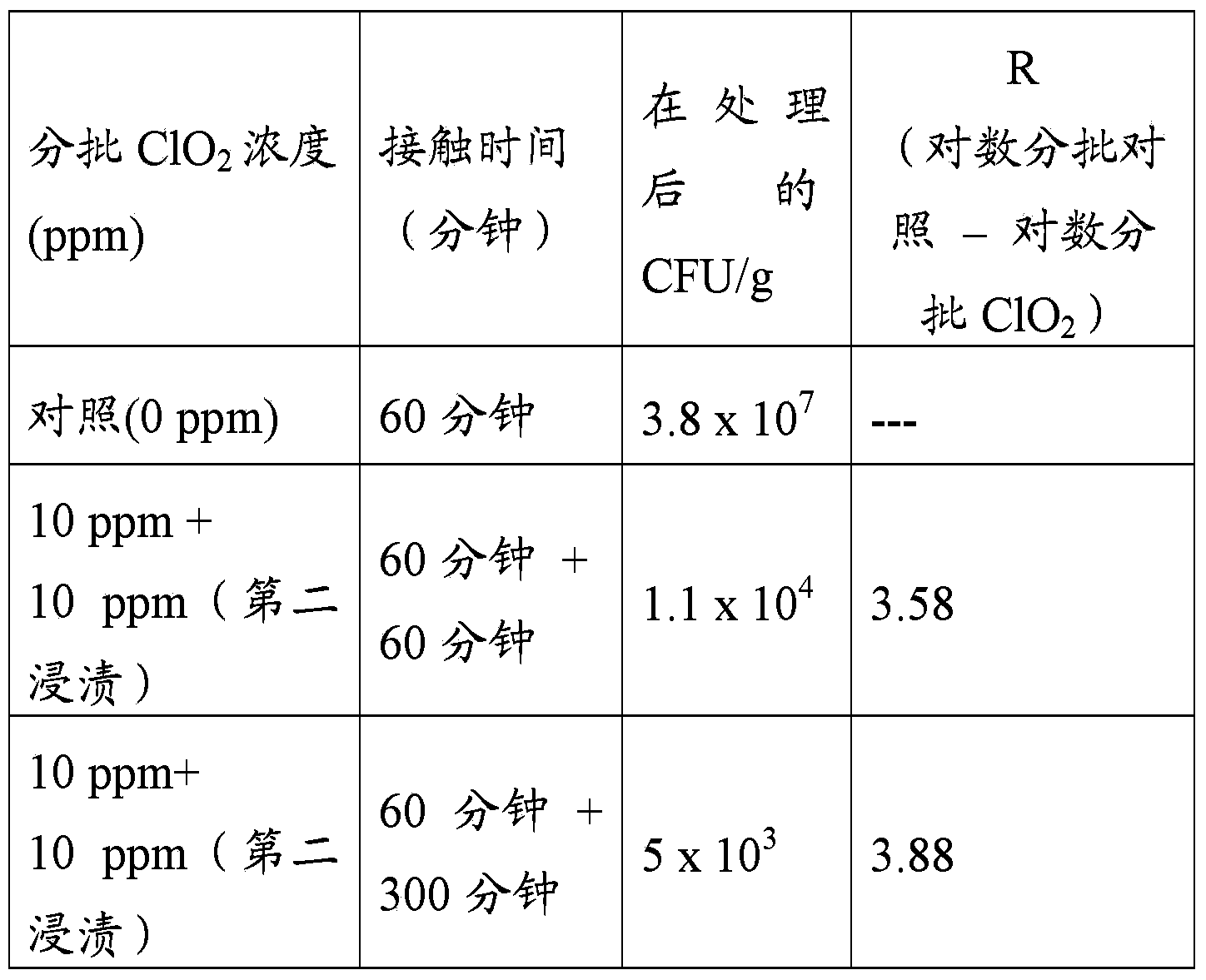

[0070] Example 2: Treatment of barley with chlorine dioxide added in a second steeping step in the steeping laboratory

[0071] More research was carried out in two trials involving a small steeping laboratory, in which harvested barley was treated with a chlorine dioxide solution in a second steeping. Again, a significant reduction in Fusarium counts was observed using chlorine dioxide for dipping.

[0072] Test program. Harvested barley from a high-load Fusarium batch was provided by the Czech Malt and Brew Institute. Initial probes (in parallel) were taken to determine the initial cell load on barley with Fusarium. Barley (1 g) was swirled in Ringer's solution (10 ml) to dissociate the cells. After vigorous vortexing, ten-fold dilution steps in sterile Ringer's solution were prepared. Pour over sterile potato agar medium from dilution step 10 -4 、10 -5 and 10 -6 Parallel 1ml samples. Chlorine dioxide-treated barley was preceded by a dilution series once washed with ...

example 3

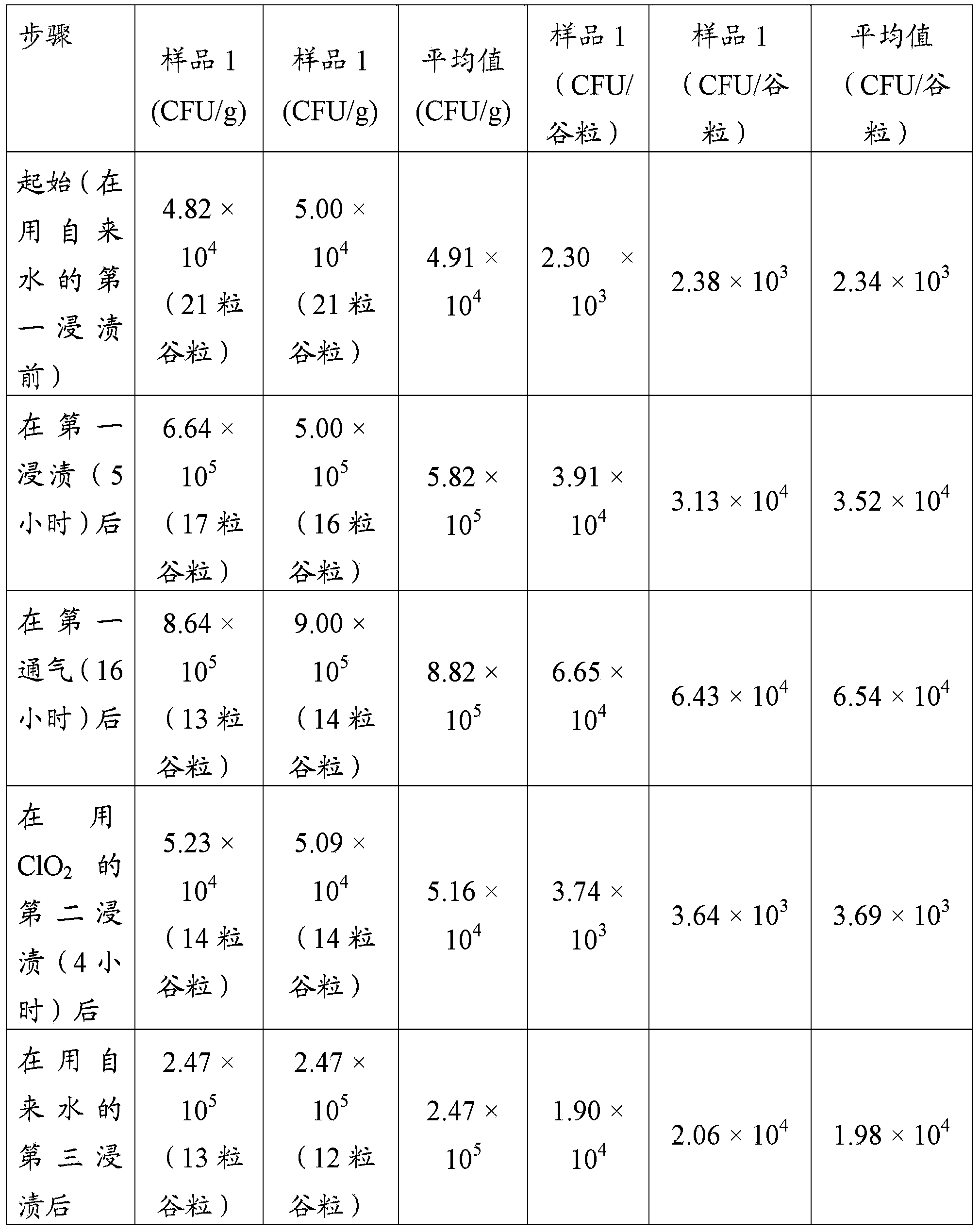

[0082] Example 3: Treatment of barley with chlorine dioxide added in a second steeping step in a steeping laboratory. compared with blank control.

[0083] A comparative test of barley batches treated with chlorine dioxide in the second steeping against a control using only tap water was performed according to the procedure described in Example 2. Chlorine dioxide in the second impregnation solution was measured initially at 11 ppm and dropped to 8 ppm at the end of the impregnation (4 hours total, data not shown). The effect on Fusarium count reduction was determined. The results are presented in Table 5.

[0084] Barley was also analyzed for representative mycotoxin content as follows. High performance liquid chromatography with mass detection (LC-MS / MS) for the determination of selected Fusarium mycotoxins (deoxynivalenol, zearalenone) and deoxynivalenol in brewing raw materials -3-glucoside. After extraction, homogenized samples are filtered and purified on SPE column...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com