Stabilizing treatment method preventing heavy metal from dissolving from powder

A technology for stabilizing treatment and heavy metals, which can be applied in the direction of protection devices against harmful chemicals, which can solve the problem of high treatment costs and achieve the effect of excellent safety.

Active Publication Date: 2014-08-27

KURITA WATER INDUSTRIES LTD

View PDF8 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In addition, there is a problem of high processing cost due to excessive addition

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

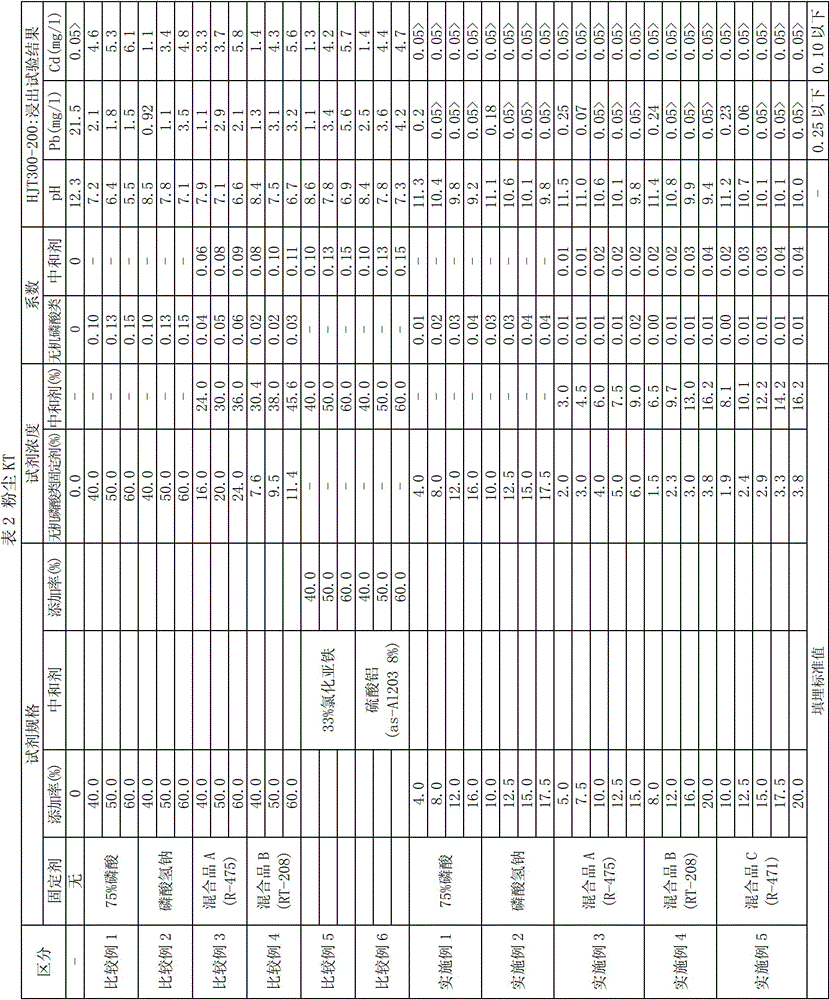

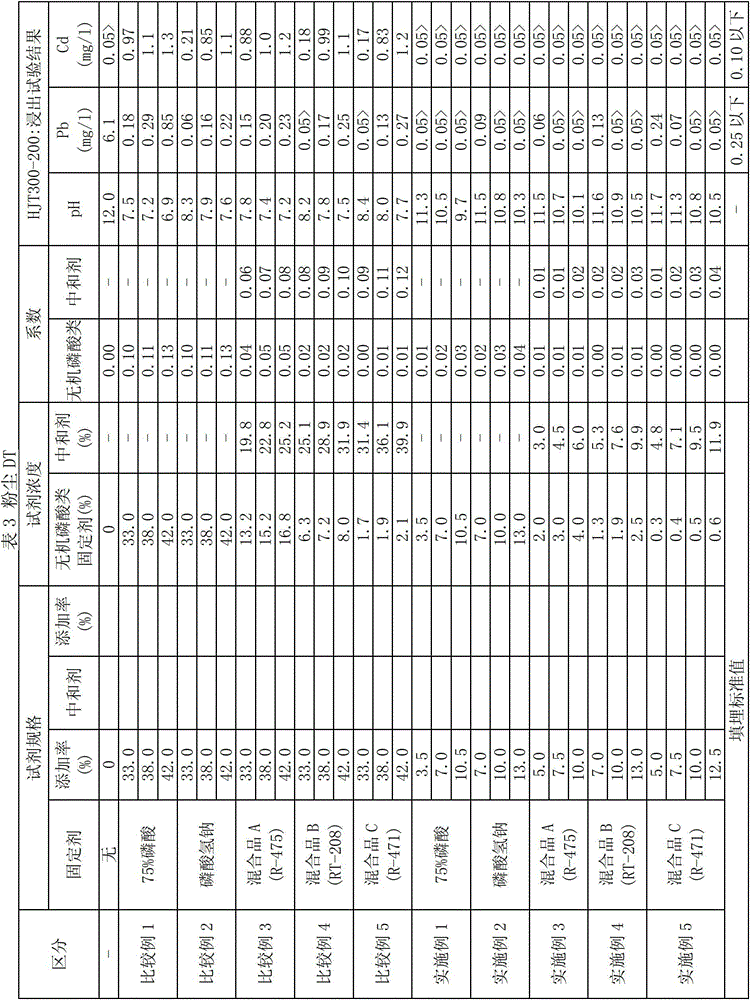

[0078] Sample 1: Dust KT discharged from municipal waste incinerators

[0079] Sample 2: Dust DT discharged from municipal waste incineration plants

[0080] The composition analysis results of dust KT and dust DT are shown in Table 1.

[0081] Table 1 Component analysis results

[0082] Analysis Project

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a stabilizing treatment method preventing heavy metal from dissolving from powder. An incineration device of common wastes or industrial wastes serves as an object; after acid gas generated by the object device is treated through quick lime and / or slaked lime, alkaline powder with remaining quick lime and / or slaked lime and with the acid consumption of 250mg-CaCO3 / g-powder is independently treated through an inorganic phosphoric acid heavy metal fixing agent or treated through the inorganic phosphoric acid heavy metal fixing agent and a neutralizer, and accordingly the heavy metal is prevented from dissolving from the powder. According to the value of acid consumption, a proper necessary addition quantity of the inorganic phosphoric acid heavy metal fixing agent and the neutralizer is determined.

Description

technical field [0001] The present invention relates to a stabilization treatment method for preventing heavy metals from leaching from dust. In order to stabilize heavy metals in dust generated from incineration equipment for general waste or industrial waste, heavy metal fixatives are used, which can be added in an appropriate amount. Treatment is a method that can make heavy metals harmless for a long time. In particular, it can stably process heavy metals according to the People's Republic of China HJT300-2007 solid waste leaching toxicity leaching method acetate buffer solution method or the US EPA method 1311TCLP method. Use the heavy metal fixative to treat the dust harmlessly, which can be landfilled. Background technique [0002] As conventional technologies, the following technologies can be cited: [0003] 1) For dust, generally add a certain amount of cement and water, after a certain period of curing, the cement is solidified, and the method of enclosing heavy...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): A62D3/33A62D101/43A62D101/08

Inventor 水品恵一

Owner KURITA WATER INDUSTRIES LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com