Preparation method of hollow capillary tubular gas chromatographic column in GDX porous polymer series

A technology of capillary chromatographic column and porous polymer, which is applied in the field of preparation of GDX porous polymer series hollow capillary gas chromatographic columns. problems, to achieve the effect of good elasticity, low column loss, and expand the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

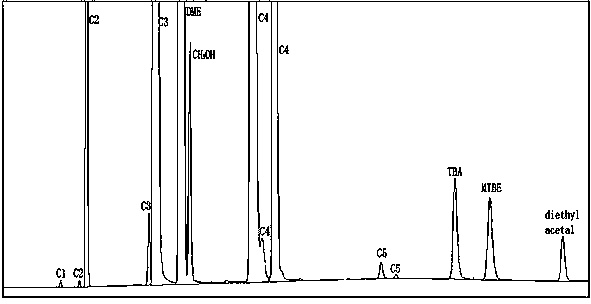

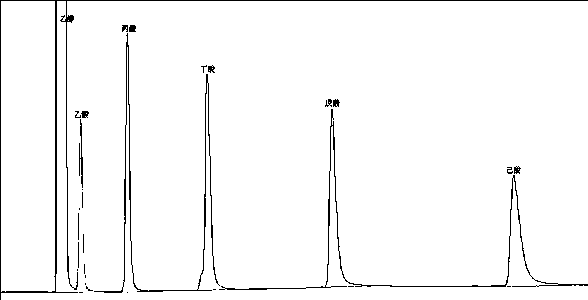

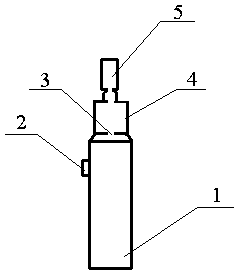

Image

Examples

Embodiment 1

[0035] The preparation method of embodiment 1GDX porous polymer series hollow capillary gas chromatography column comprises the following steps:

[0036] (1) First rinse the inner wall of the elastic quartz capillary column with 1mol / LHF, then rinse the inner wall of the elastic quartz capillary column with clear water for 3 times, and finally install the rinsed elastic quartz capillary column on the chromatographic instrument, and purge with nitrogen gas, And heated to 200 ° C, kept for 6h, that is, the pretreated elastic quartz capillary column.

[0037] Wherein: the inner diameter of the elastic quartz capillary is 0.32 mm, and the length is 15 meters.

[0038] (2) Preparation of polymer microsphere seed suspension: disperse GDX polymer nanospheres in the dispersant, and ultrasonically stir and disperse for 60 minutes at a temperature of 20°C and a power of 100W to obtain a polymer with a mass concentration of 1.0%. Microsphere seed suspension.

[0039] in:

[0040] GDX po...

Embodiment 2

[0050] The preparation method of embodiment 2GDX porous polymer series hollow capillary gas chromatography column comprises the following steps:

[0051] (1) First rinse the inner wall of the elastic quartz capillary column with 3mol / LHF, then rinse the inner wall of the elastic quartz capillary column with clear water 4 times, and finally install the rinsed elastic quartz capillary column on the chromatographic instrument, and purge with nitrogen, And heated to 300 ° C, keep 4h, that is, the pretreated elastic quartz capillary column.

[0052] Wherein: the inner diameter of the elastic quartz capillary is 0.53 mm, and the length is 60 meters.

[0053] (2) Preparation of polymer microsphere seed suspension: disperse GDX polymer nanospheres in the dispersant, and ultrasonically stir and disperse for 30 minutes at a temperature of 25°C and a power of 150W to obtain a polymer with a mass concentration of 5%. Microsphere seed suspension.

[0054] in:

[0055] GDX polymer nano-m...

Embodiment 3

[0065] The preparation method of embodiment 3GDX porous polymer series hollow capillary gas chromatography column comprises the following steps:

[0066] (1) First rinse the inner wall of the elastic quartz capillary column with 2mol / LHF, then rinse the inner wall of the elastic quartz capillary column with clear water for 3 times, and finally install the rinsed elastic quartz capillary column on the chromatographic instrument, and purge with nitrogen, And heated to 250 ℃, keep 5h, namely the pretreated elastic quartz capillary column.

[0067] Wherein: the inner diameter of the elastic quartz capillary is 0.40 mm, and the length is 35 meters.

[0068] (2) Preparation of polymer microsphere seed suspension: disperse GDX polymer nanospheres in the dispersant, and ultrasonically stir and disperse for 45 minutes at a temperature of 22°C and a power of 125W to obtain a polymer with a mass concentration of 3%. Microsphere seed suspension.

[0069] in:

[0070] GDX polymer nano-m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com