Preparation method of catalyst for preparing methacrylic acid through oxidation of methylacrolein

A technology of methacrylic acid and methacrolein, which is applied in the preparation of organic compounds, catalysts for physical/chemical processes, preparation of carboxylate, etc. It can solve the problems of high cost, low space-time yield, short catalyst life, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

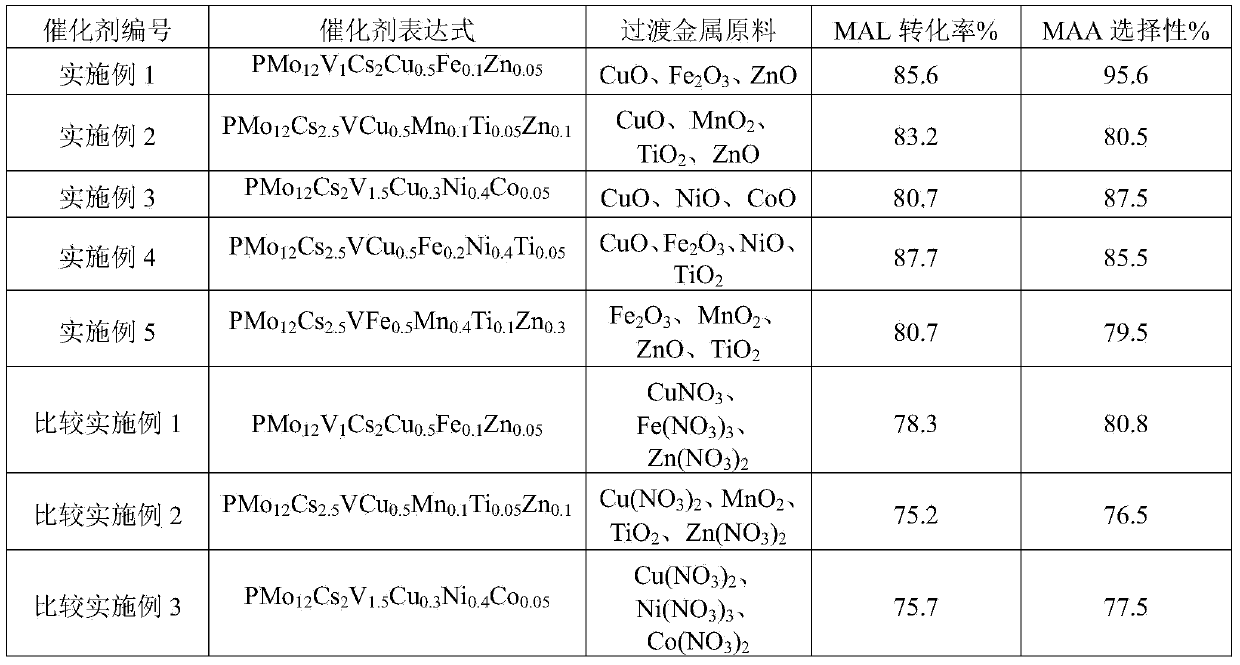

Embodiment 1

[0026] 1 kg MoO 3 Add 15L of deionized water, stir for 30 minutes until uniform, and slowly add 283ml of phosphoric acid with a mass fraction of 17%. The temperature was raised to 105° C., condensed and refluxed for 3 hours, and the slurry turned into a yellow transparent solution A. After cooling to room temperature, unreacted solid particles were filtered off.

[0027] The above clear solution was warmed up to 85°C, and 52.6gV was added 2 o 5 , condensed to reflux, stirred for 2h, then added 23.2gCuO, 4.7gFe 2 o 3 , 9.4gZnO, condensed and refluxed, stirred for 2h. Finally add 225.7gCsNO 3 , Condensed to reflux, stirred for 3h. Stop condensation and reflux at 85°C, carry out concentrated drying, stop stirring when the viscosity of the slurry increases significantly, take out the semi-solid slurry, and place it in a blast drying oven at 80°C for 24 hours. The expression for the catalyst (ignoring hydrogen and oxygen) is:

[0028] PMo 12 V 1 Cs 2 Cu 0.5 Fe 0.1 Zn ...

Embodiment 2

[0032] The preparation method of solution A and V 2 o 5 The addition amount is as embodiment 1, adds 23.2gCuO, 5.0gMnO in the slurry after reaction 2 , 2.3gTiO 2 And 9.4gZnO, reflux condensation at 85°C for 2h. Finally add 282.1gCsNO 3 , Condensed to reflux, stirred for 3h. The expression of the catalyst is:

[0033] PMo 12 Cs 2.5 VCu 0.5 mn 0.1 Ti 0.05 Zn 0.1

[0034] The processing method of catalyst in subsequent steps is as embodiment 1. The evaluation method of the catalyst is as in Example 1, the conversion rate of MAL is 83.2%, and the selectivity of MAA is 80.5%.

Embodiment 3

[0036] The preparation method of solution A is as embodiment 1, in the filtered solution A, add V 2 o 5 78.9g, reflux condensed at 85°C, stirred for 2h, added CuO13.9g, 17.3gNiO, 2.2gCoO, refluxed condensed at 85°C, stirred for 2h, finally added 225.7gCsNO 3 , Reaction 3h. The expression of the catalyst is:

[0037] PMo 12 Cs 2 V 1.5 Cu 0.3 Ni 0.4 co 0.05

[0038] Catalyst follow-up treatment step is as embodiment 1, and the evaluation method of catalyzer is as embodiment 1, and the filling of catalyst is that the volume ratio of catalyst particle and quartz sand is 4:1, and the transformation rate of MAL is 80.7%, and the selectivity of MAA is 87.5% %.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com