Surface hardening treatment method for main cutter board of loader shovel

A technology of hardening treatment and main knife plate, which is applied in the direction of welding medium, arc welding equipment, welding/cutting medium/material, etc., can solve the problems of low hardness of main knife plate, high use cost, short service life, etc., and achieve firm connection and stacking The effect of fast welding speed and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

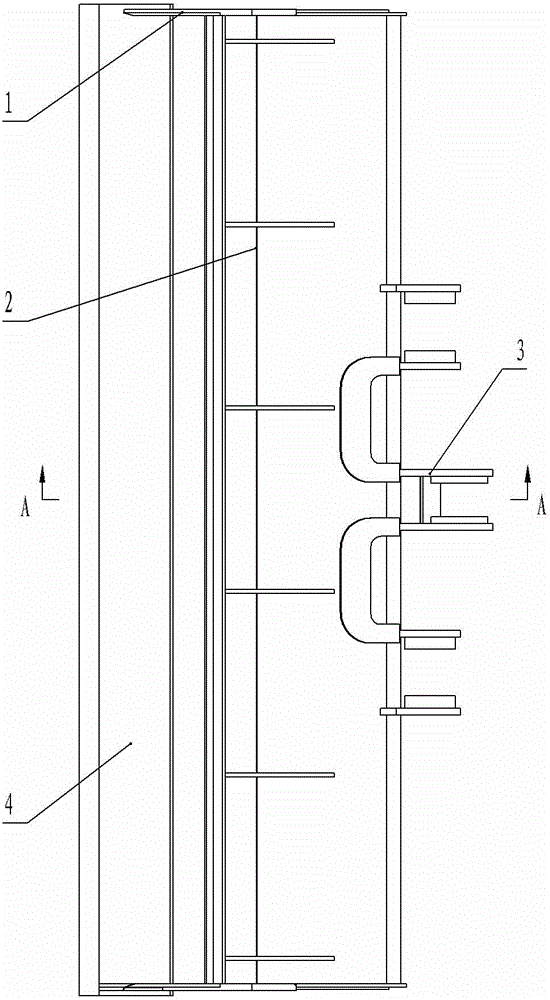

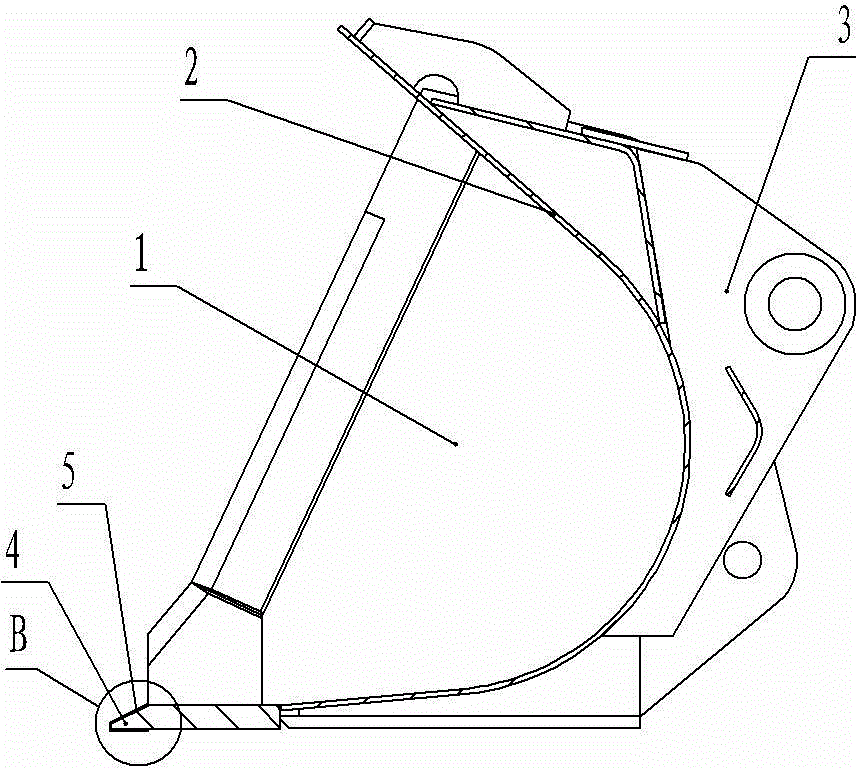

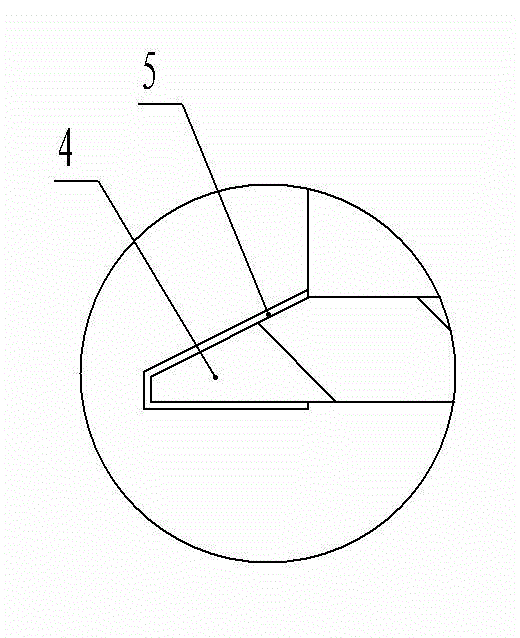

[0015] A surface hardening treatment method for the main knife plate of the loader bucket: Surfacing welding is performed on the surface of the main knife plate of the loader bucket, so that the outer surface of the cutting edge forms a metal overlay welding layer 5 with a thickness of 3 mm and a surface hardness greater than HRC40, Such as figure 2 , image 3 As shown; the surfacing welding process adopts carbon dioxide gas shielded welding, and its welding parameters are: the welding wire material is hard alloy surfacing welding with a diameter of 1.6 mm, a carbon content of 0.3%, a chromium content of less than 5%, and a molybdenum content of less than 4%. Wear-resistant welding wire, the welding current is 220 amperes, the arc voltage is 24 volts, and the flow rate of carbon dioxide gas is 12 liters / minute; the surface of the main knife plate of the loader bucket is surfacing one by one in the direction parallel to the cutting edge.

Embodiment 2

[0017] A surface hardening treatment method for the main knife plate of the loader bucket: carry out surfacing welding on the surface of the main knife plate of the loader bucket, so that the outer surface of the cutting edge forms a metal surfacing layer with a thickness of 5 mm and a surface hardness greater than HRC40, such as figure 2 , image 3 As shown; the surfacing welding process adopts carbon dioxide gas shielded welding, and its welding parameters are: the welding wire material is hard alloy surfacing welding with a diameter of 1.6 mm, a carbon content of 0.6%, a chromium content of less than 5%, and a molybdenum content of less than 4%. Wear-resistant welding wire, the welding current is 240 amperes, the arc voltage is 26 volts, and the flow rate of carbon dioxide gas is 16 liters / minute; the surface of the main knife plate of the loader bucket is surfacing one by one in a direction parallel to the cutting edge.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com