Digital camera auto-focus system and its auto-focus method based on weld pool

A technology of welding molten pool and auto-focus, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve problems such as clogging and affecting welding quality, and achieve the effect of high definition and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

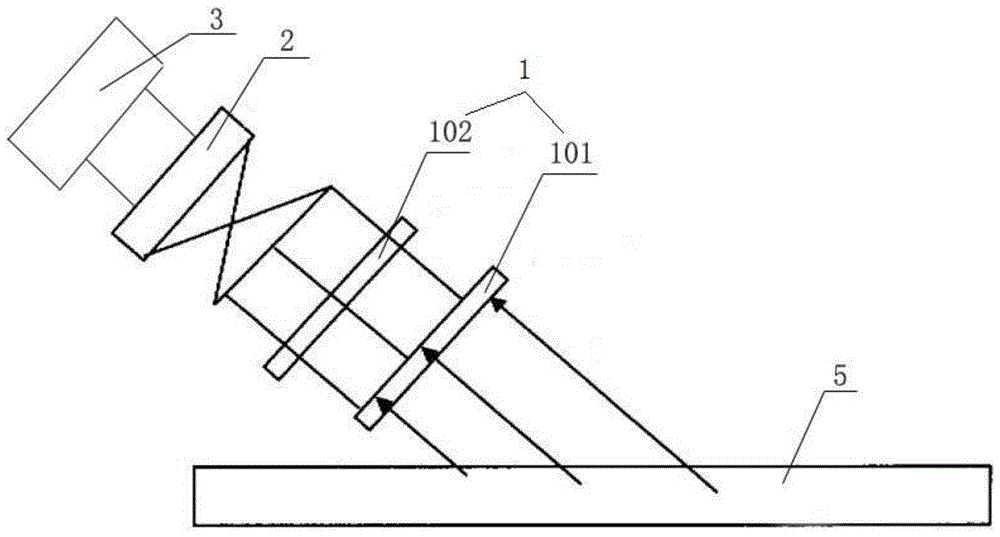

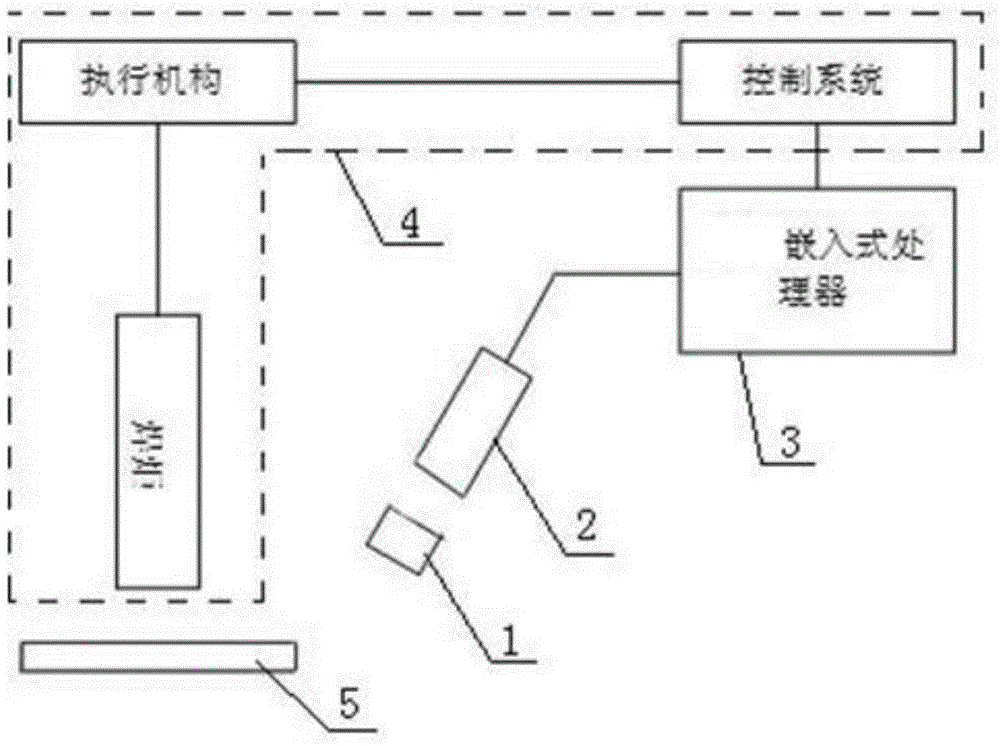

[0049] Figure 1 to Figure 2 Disclosed in is a digital camera auto-focus system based on a welding pool, including a filter module 1, a camera 2, and an embedded processor 3, and the filter module 1 includes a heat insulating glass 101, a filter 102, The insulating glass 101 and the optical filter 102 are sequentially arranged between the welding workpiece 5 and the camera 2 , the camera 2 is connected to the embedded processor 3 , and the embedded processor 3 is also connected to the control system of the welding equipment 4 .

[0050] The heat insulating glass 101 is arranged between the welding workpiece 5 and the optical filter 102 to isolate the heat generated during the welding pool; the heat insulating glass 101 is mainly responsible for isolating infrared radiation and eliminating the interference of infrared heat radiation.

[0051] The peak wavelength of the optical filter 102 is 6328 Å, and the peak transmittance of the optical filter is 63%; the optical filter 102 ...

Embodiment 2

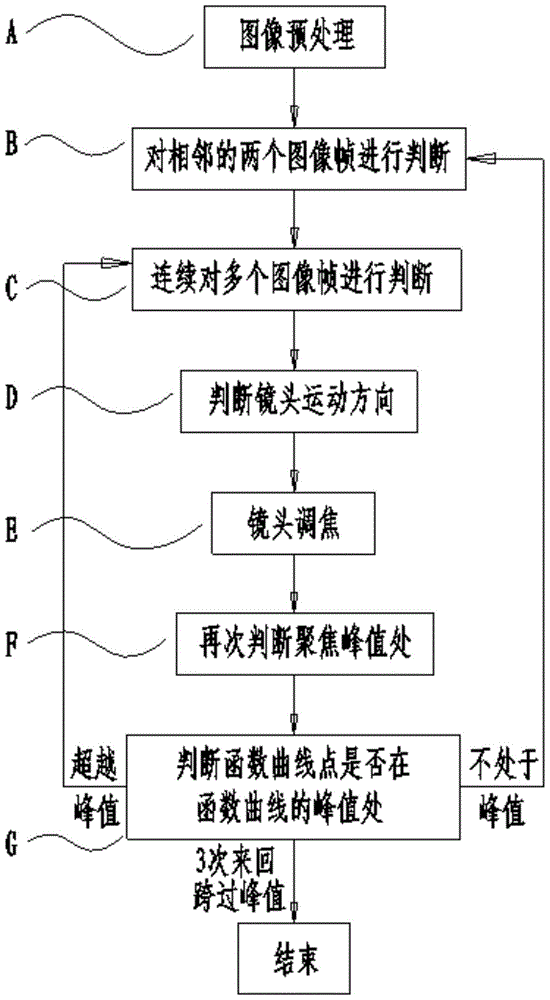

[0055] An automatic focusing method of a digital camera automatic focusing system based on a welding pool, the method uses an image definition evaluation function to judge adjacent image frames in real time, and uses a climbing method for the image definition curve formed by the image definition evaluation function. Slope method, adjust the focal length magnification of the camera lens in real time, so that the curve point of the image definition evaluation function is at the peak position of the curve, so as to achieve the effect of image clarity; At the peak of the curve, the system adjusts the reverse movement of the camera lens, automatically searches and adjusts the focus to stabilize the image at the clearest point.

[0056] The above-mentioned auto-focusing method of the digital camera auto-focusing system based on the weld pool comprises the following steps (for the flow chart, see image 3 ):

[0057] A. Image preprocessing:

[0058] After the embedded processor rec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com