New Process of Mother Liquor Recovery

A mother liquor recovery and new process technology, applied in the chemical industry, sustainable manufacturing/processing, alkali metal chloride, etc., can solve the problems of low salt quality, large investment, pollution, etc., and achieve low equipment cost and low investment. , the simple effect of the tank shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

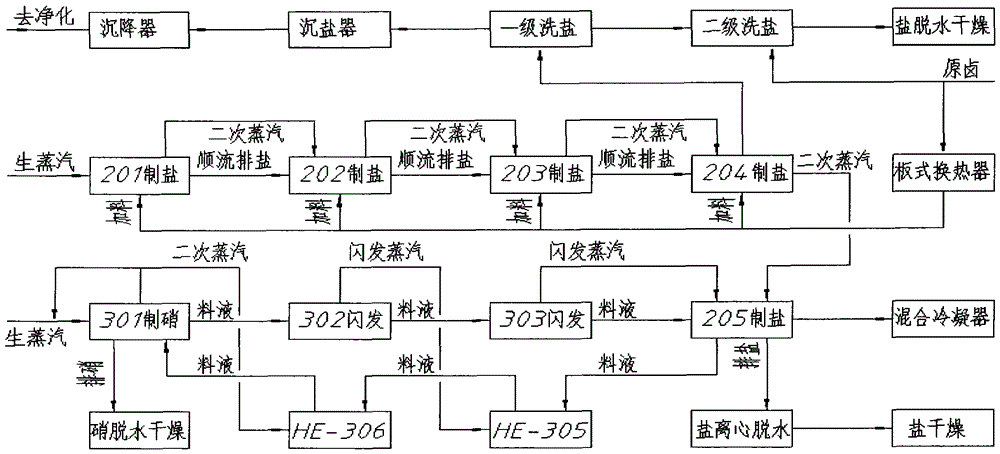

[0017] as attached figure 1 As shown, the new mother liquor recovery process described in this embodiment comprises the following steps:

[0018] S1. Raw brine flows into 200 system I, II, III, and IV effect evaporation tanks EV201, EV202, EV203, EV204 after exchanging heat with condensed water through plate heat exchanger, and raw steam enters heating chamber HE201.

[0019] S2. The secondary steam generated by the evaporation of brine enters the heating chamber of the next effect in turn, and the salt slurry is discharged from effect I to effect II, effect II to effect III, effect III to effect IV, and effect IV The salt slurry is pumped out by the salt discharge pump, and after passing through the cyclone, the top of the cyclone flows back to the 200 system.

[0020] S3. The underflow of the cyclone passes through the float washer, is washed by the raw brine, then dehydrated, dried, and then measured and packaged to obtain the salt product. After the overflow of the float ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com