Chain guide

A technology of chains and guides, which is applied to belts/chains/gears, mechanical equipment, transmission devices, etc., can solve the problems of material waste, increased manufacturing costs, and increased manufacturing hours, so as to reduce manufacturing costs, reduce material waste, reduce The effect of small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

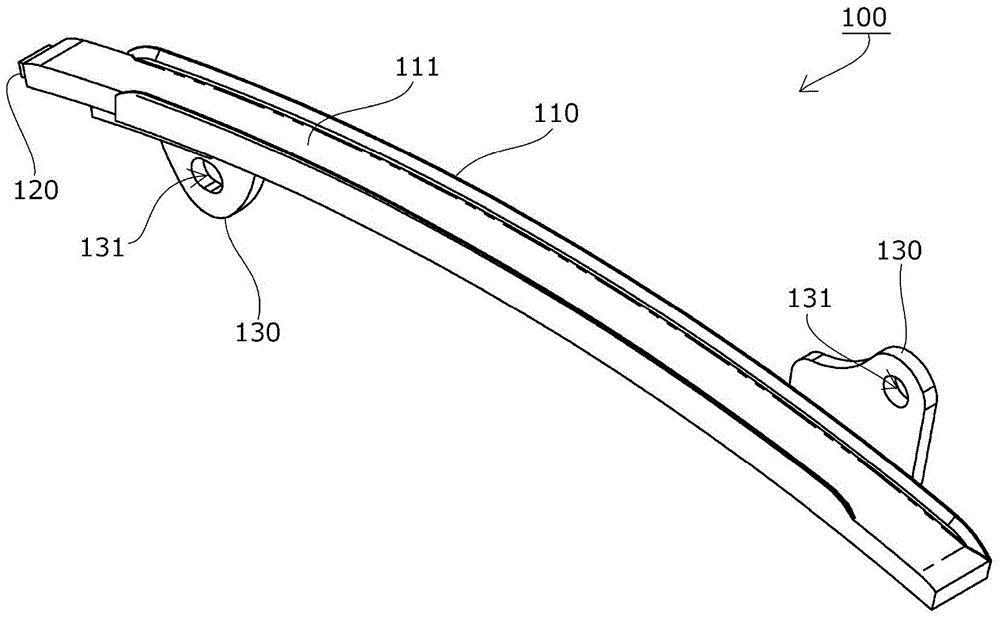

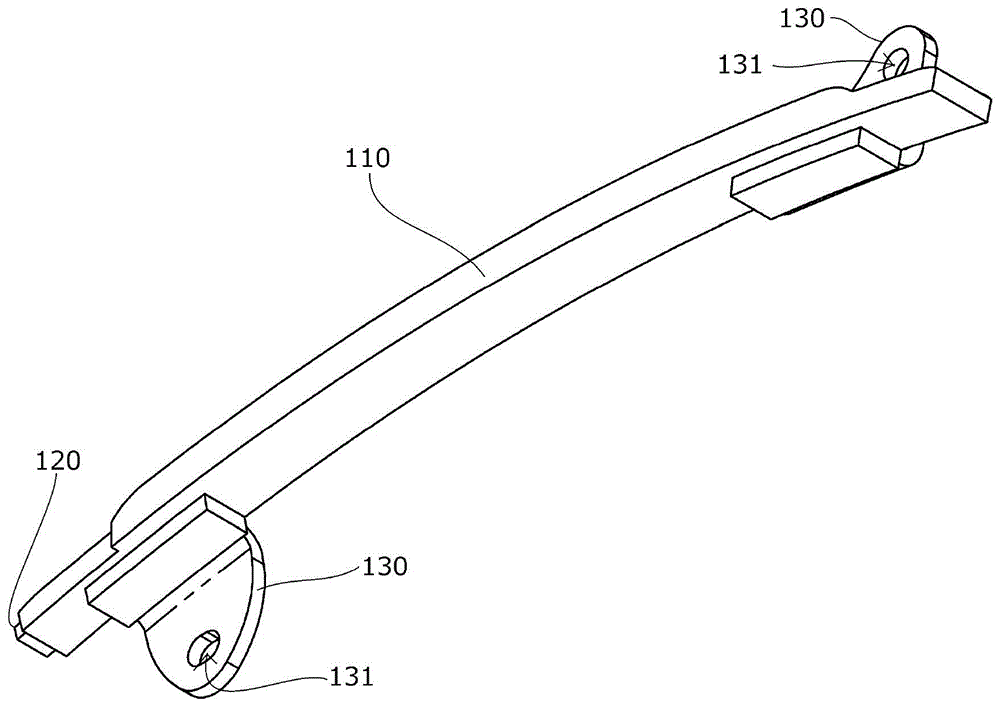

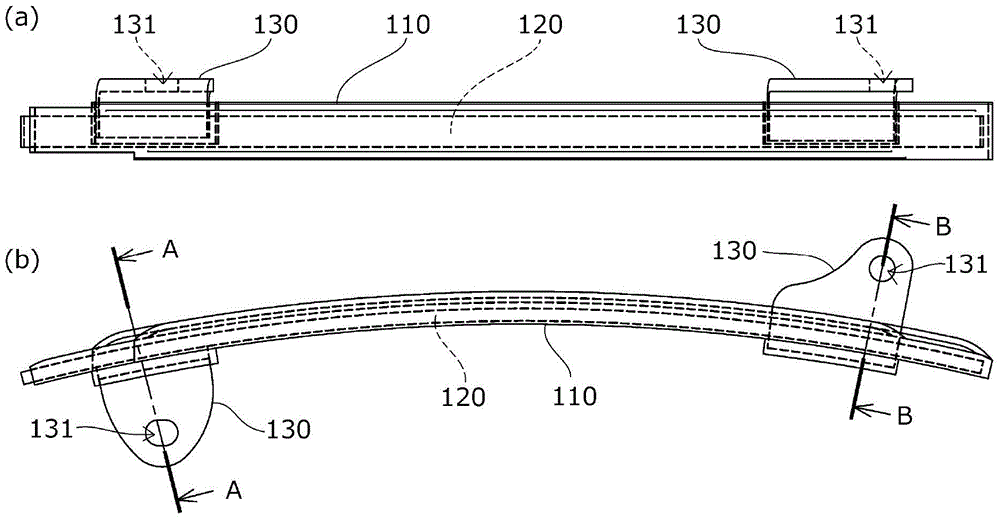

[0112] The chain guide 100 (fixed guide) according to the first embodiment of the present invention will be described with reference to the drawings.

[0113] The chain guide 100 is a chain guide suitable for the aforementioned known timing systems, such as Figure 1 to Figure 5 As shown, it is provided with: a guide block 110, which slides and guides the moving chain; and a base member 120, which reinforces the guide block 110 along the moving direction of the chain.

[0114] The base member 120 extends in the chain movement direction while having a predetermined curved shape along the chain movement direction, and is formed, for example, by punching out of one rolled steel plate.

[0115] The mounting member 130 is formed separately from the guide block 110 and the base member 120 and has: a mounting portion 133;

[0116] Mounting holes 131 are provided in the mounting portion 133 through which bolts and the like are inserted and fixed to an engine compartment or the like. ...

Embodiment 2

[0126] like Figure 6 to Figure 8 As shown, the chain guide 100A according to the modified example of the first embodiment of the present invention is as follows, the fixing piece 132A of the mounting member 130A is provided with the filling hole 134 filled with the material of the guide block 110, and the other structure is the same as that of the aforementioned first The chain guide 100 according to the first embodiment is the same (the same reference numerals are given to the same members as those of the chain guide 100 , and the perspective view is omitted because it is the same as that of the chain guide 100 ).

[0127] As a result, when the guide block 110 is formed by injection molding or the like in a state where the base member 120 and the fixing piece 132A of the attachment member 130A are inserted, a chain that more reliably fixes the guide block 110 , the base member 120 , and the attachment member 130A can be obtained. 100 A of guides can exhibit the same special ...

Embodiment 3

[0129] like Figure 9 to Figure 12 As shown, the chain guide 100B according to another modified example of the first embodiment of the present invention is as follows. The base member 120 and the fixing piece 132 of the mounting member 130 are previously fixed and integrated by an appropriate method such as spot welding, and the guide block 110B engages with the base member 120 to form an integrated fixed guide block 110B, base member 120, and mounting member 130. Other structures are the same as those of the chain guide 100 according to the first embodiment described above (the same as the chain guide 100). components marked with the same symbol).

[0130] Like the aforementioned known guide block 510, the guide block 110B of this modified example is constituted as follows. End locking pieces 112 are respectively provided at both ends in the chain movement direction, and a plurality of side locking pieces 112 are provided at appropriate positions in the width direction. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com