Device and method for recycling afterheat of smoke of steam boiler

A flue gas waste heat and steam boiler technology, applied in separation methods, chemical instruments and methods, liquid degassing, etc., can solve problems such as changes in tail smoke exhaust, influence of operating conditions, changes in boiler feed water rate, etc., to improve feed water Fluctuations in temperature, equilibrium energy flow rate, fuel saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

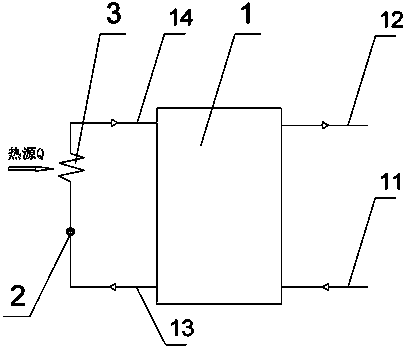

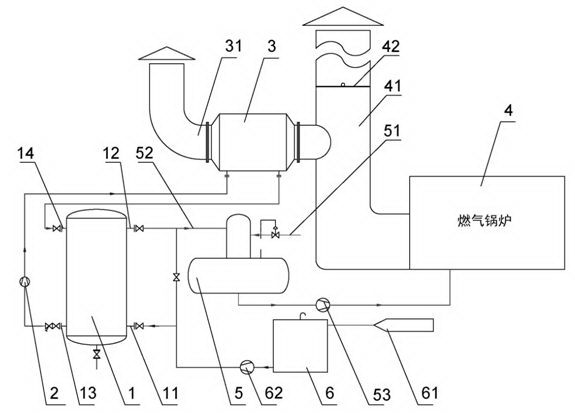

[0033] combine figure 1 with figure 2 The technical solution of the present invention is further described.

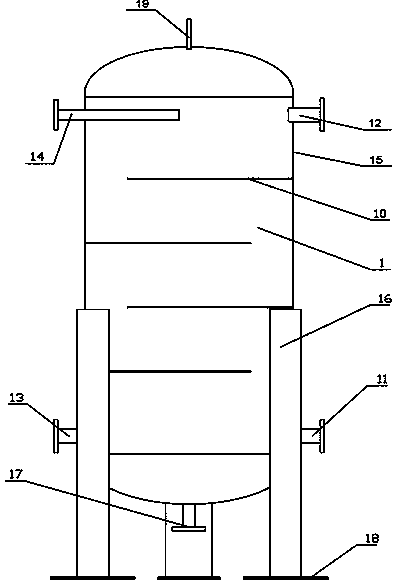

[0034] The original system includes a gas boiler 4 , a connected boiler tail flue 41 , a deaerator 5 , a boiler feed water pump 53 , a feed water tank 6 , and a feed water pump 62 . The schematic diagram of a steam boiler flue gas waste heat recovery and utilization device with frequent load changes in the present invention is as follows figure 2 As shown, it includes a buffer water tank 1, one side of the bottom of the buffer water tank 1 is provided with an intermittent water supply inlet 11, and the other side of the bottom of the buffer water tank 1 is provided with a continuous circulating cold water outlet 13 connected to one side of the circulating water pump 2, and the circulating water pump 2 The other side is connected to the inlet of the heat exchanger 3, the outlet of the heat exchanger 3 is connected to the continuous circulation hot water inlet 14 on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com