Blast furnace gas burning assisting device

A technology of blast furnace gas and pores, which is applied in the field of blast furnace gas accompanying combustion devices and combustion devices, can solve the problems of combustion stability and other problems, and achieve the effects of improving combustion-supporting conditions, increasing contact area, and increasing contact time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

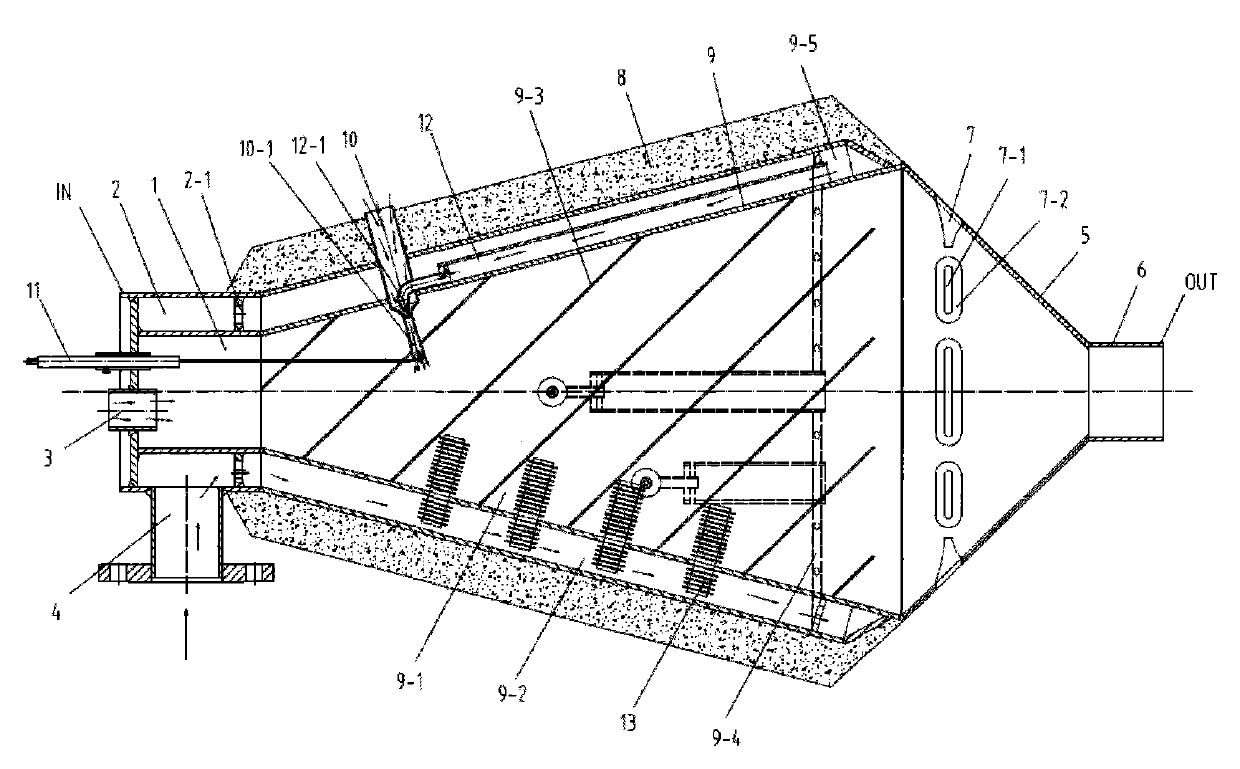

[0020] The blast furnace gas accompanying firing device of this embodiment is shown in Fig. 1 , a cylindrical main body A with a horizontal axis has an inlet port IN and an outlet port OUT. The inlet IN is composed of a central air inlet passage 1 and an air inlet ring 2 surrounding the air inlet passage. The air inlet passage 1 communicates with the atmosphere through the axial tubular secondary air outlet 3 near the center of the end, and the air inlet ring 2 connects with the blast furnace gas through the radial gas inlet 4 .

[0021] The outlet port OUT is composed of a tapered flame stabilization cone 5 and a tubular flame injection port 6 at its outer end. The flame stabilization cone 5 has a group of pressure relief nozzles 7 evenly distributed around the circumference, and each pressure relief nozzle 7 is formed by a mouth slit extending in the circumferential direction. 7-1 and the guide pipe 7-2 that is gradually narrowed in the flame-stabilizing cone 5 by the mouth ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com