Micro component extension test device

A tensile test and micro-component technology, applied in the direction of applying repeated force/pulsation force to test the strength of materials, can solve the problems of expensive instruments, large dispersion of test data, and no longer applicable test methods and devices, so as to facilitate installation Reliable effect of debugging and clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

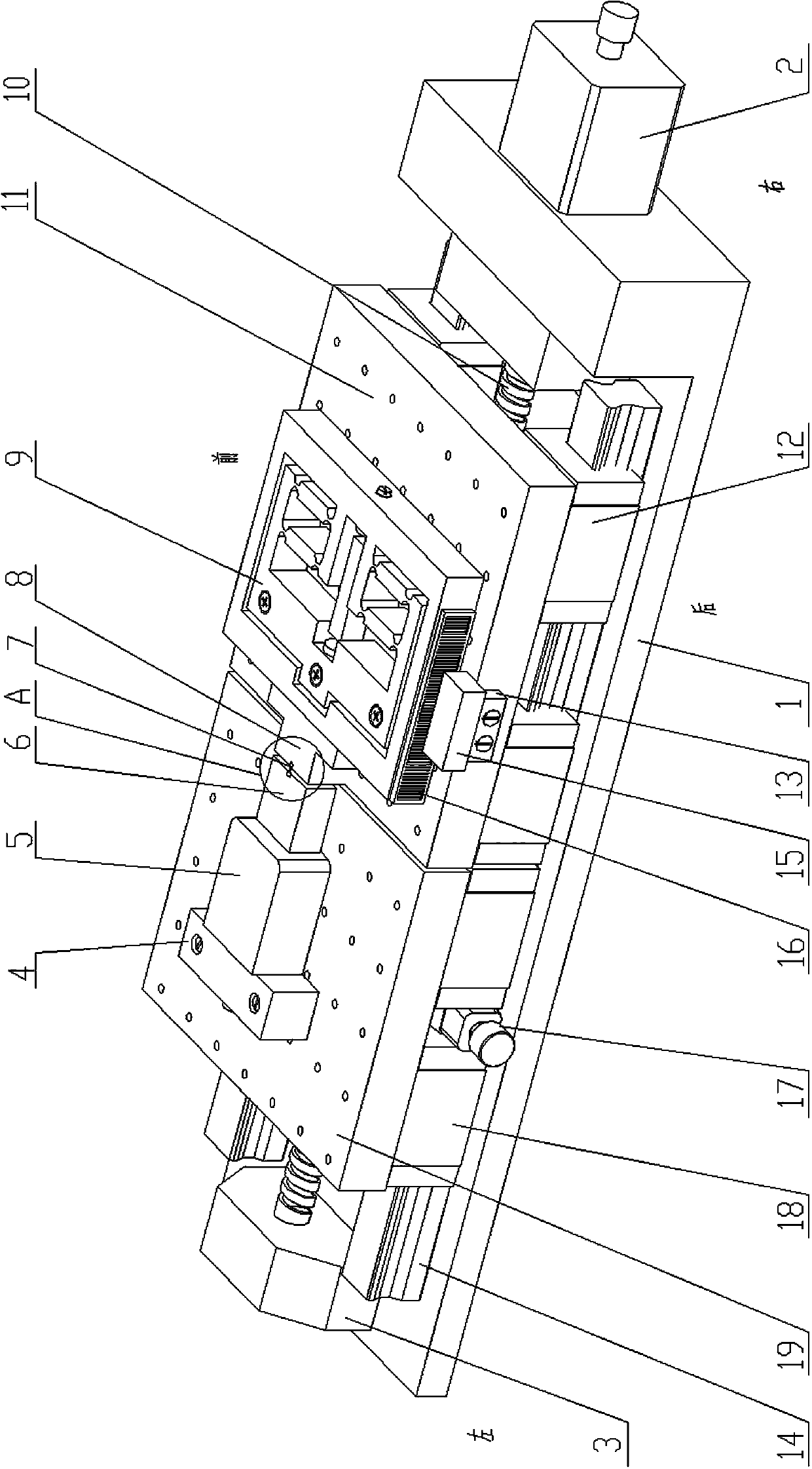

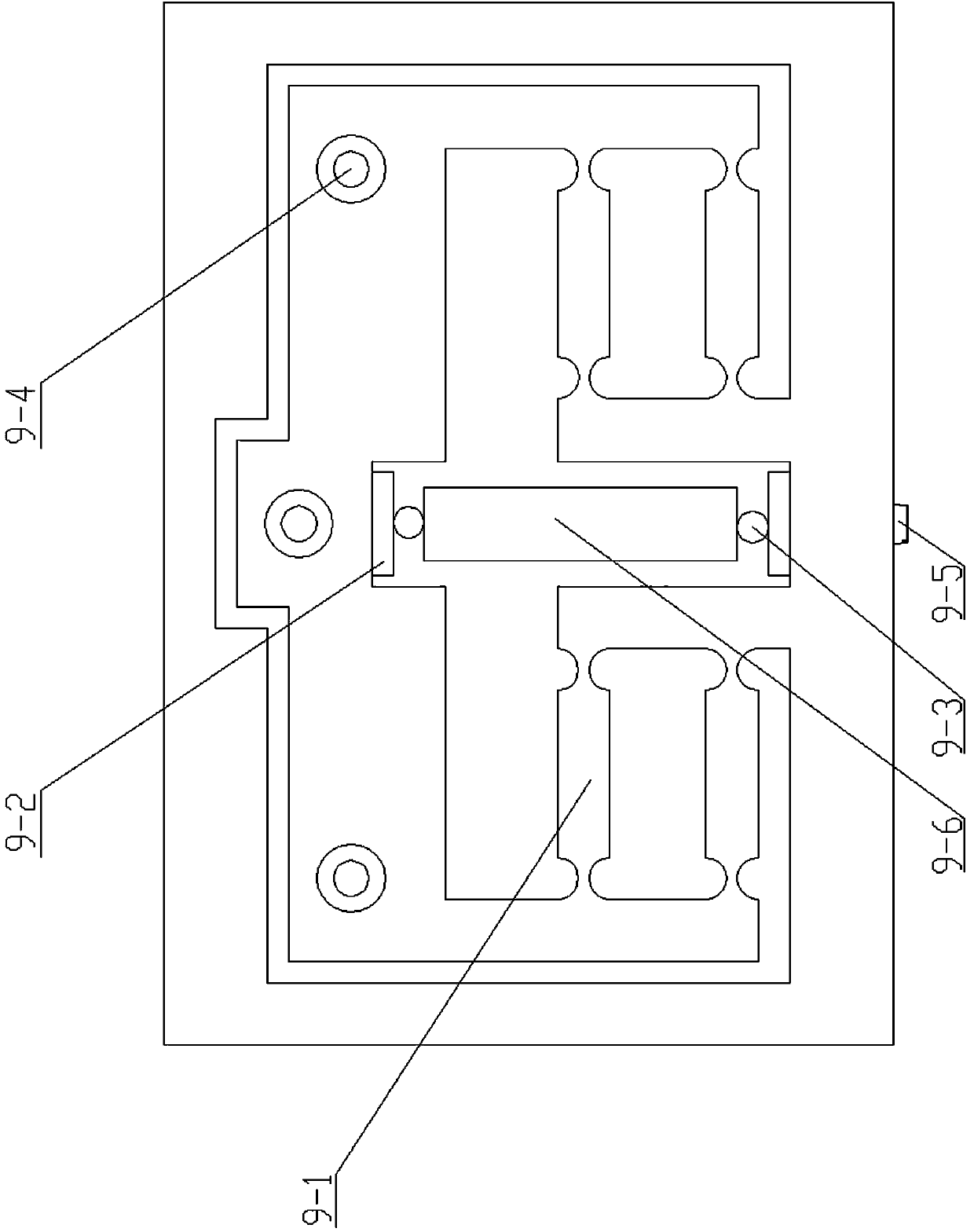

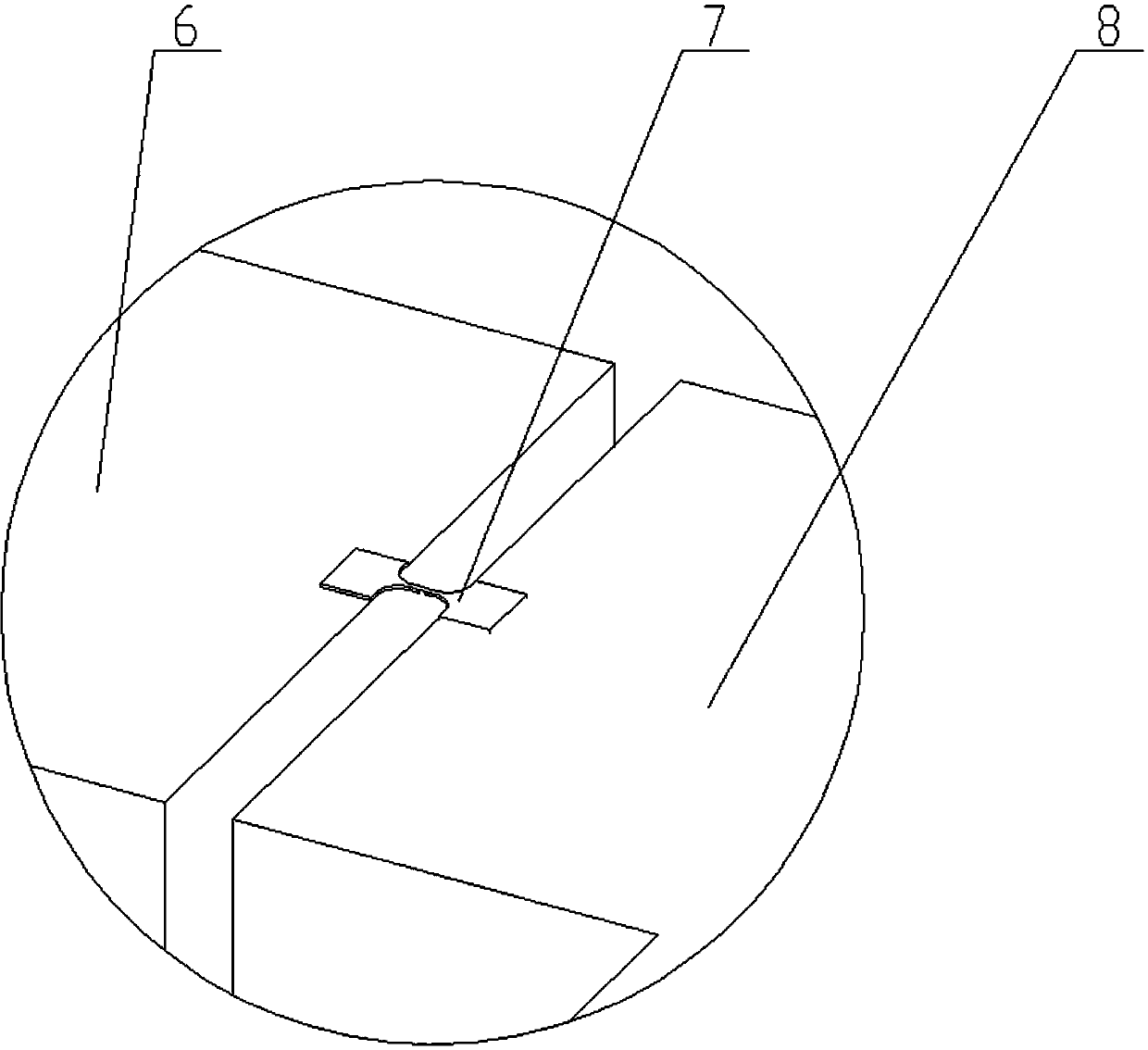

[0015] Such as Figure 1~Figure 3 As shown, the micro-component tensile testing device includes a precision drive unit 9, a micro force sensor 5, a linear grating measuring device, a high-precision electric shift stage, a stage, a force sensor fixing block 4, and two fixing parts 17. The high-precision electric moving stage includes a left loading platform 19, a right loading platform 11, a screw nut pair 10, an L-shaped base 1, a support base 3, a stepping motor 2, four left sliders 18, and four right sliders. Block 12, two guide rails 14, the described stage includes a moving stage 8 and a static stage 6, and the described linear grating measuring device includes a grating ruler reading head installation frame 13, a reading head 15 and a grating ruler 16 ,

[0016] The long plate of the L-shaped base 1 is arranged horizontally, and the two guide rails 14 are parallel to the long sides of the L-shaped base 1 and fixed on the long plate of the L-shaped base 1; the left loadin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com