Adhesive for solar battery back sheets

A technology for solar cells and adhesives, applied in the direction of adhesive types, polyurea/polyurethane adhesives, adhesives, etc., to achieve the effects of improving initial tack, excellent durability, and excellent productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

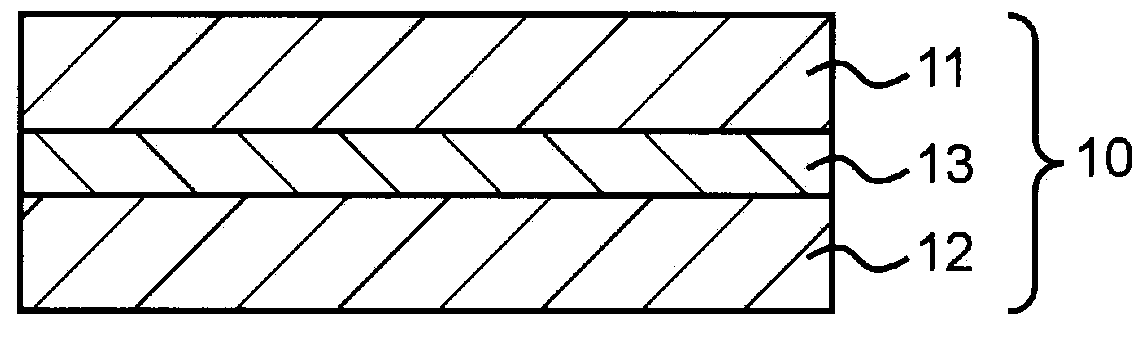

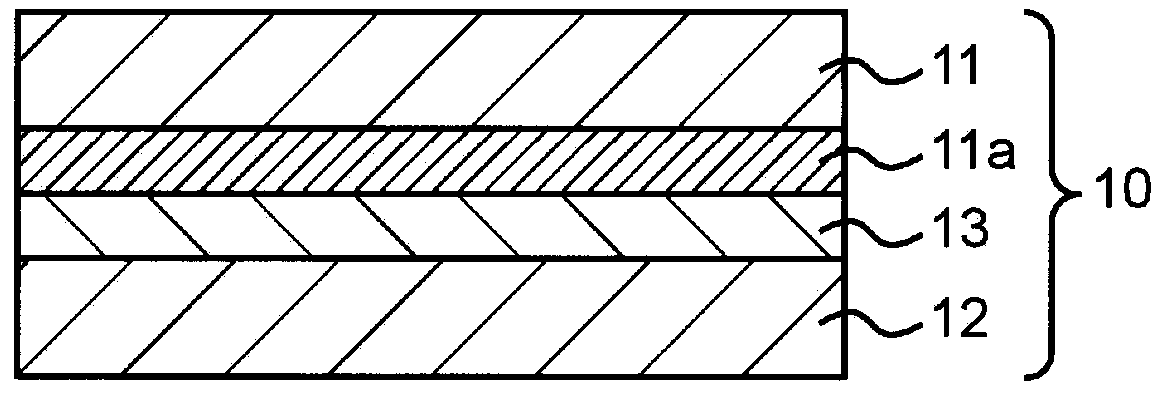

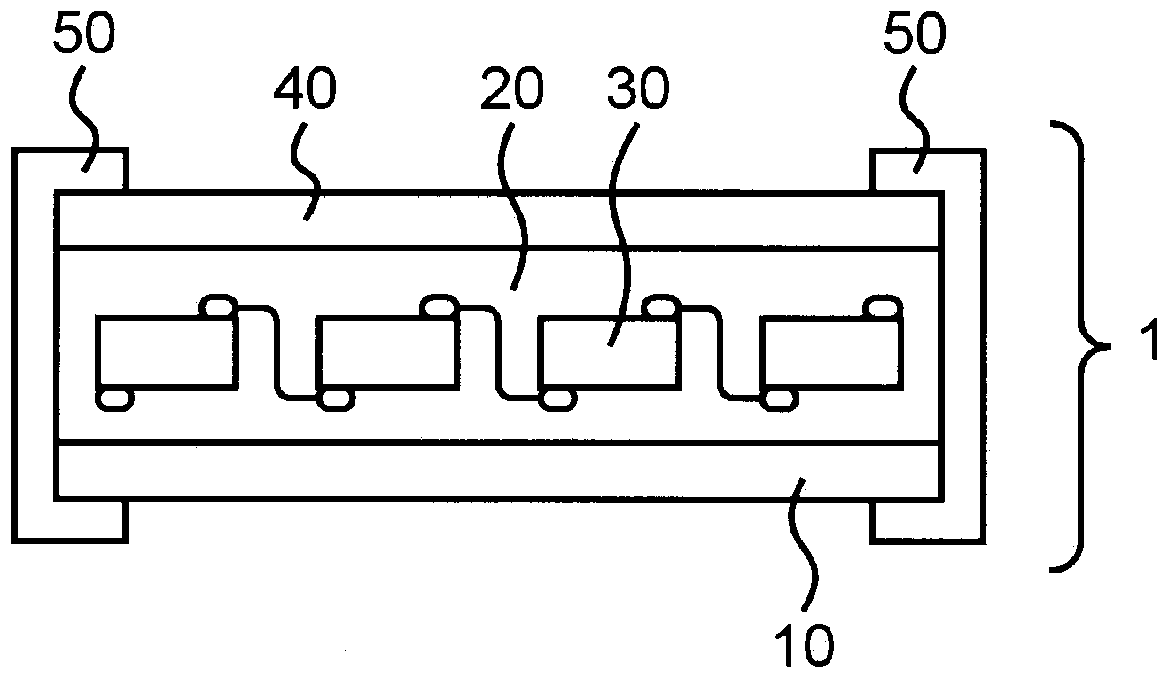

Image

Examples

Embodiment 1

[0177]

[0178] As shown in Table 3, 83.1 g of Polymer 1 [208 g of an ethyl acetate solution of Polymer 1 (solid content: 40.0% by weight)] and 16.9 g of SUMIDULE N3300 manufactured by Sumika Bayer Urethane Co., Ltd. ( trade name), and then mixed to prepare a binder solution. Using the solution thus prepared as an adhesive for solar cell back sheets, the following tests were performed.

[0179]

[0180] First, the adhesive for solar battery back sheets of Example 1 was applied to a transparent polyethylene terephthalate (PET) sheet (manufactured by Mitsubishi Polyester Film Corporation, trade name O300EW36), so that the The weight of solid components is 10g / m 2 , and then dried at 80° C. for 10 minutes to obtain an adhesive-coated PET sheet 1 .

[0181] Then, a surface-treated transparent polyolefin film (linear low-density polyethylene film manufactured by Futamura Chemical Co., Ltd., trade name LL-XUMN #30) was placed on the adhesive side of the adhesive-coated PET she...

Embodiment 2 to 12 and comparative example 1 to 3

[0211] In the same manner as in Example 1, adhesives for solar cell back sheets were prepared according to the compositions shown in Tables 3 and 4, and then evaluated. The evaluation results are shown in Tables 3 and 4.

[0212] table 3

[0213]

[0214] Table 4

[0215]

[0216] As shown in Tables 1 to 4, since the adhesives for solar battery back sheets of Examples 1 to 12 contain polyurethane resins obtainable by reacting acrylic polyols with isocyanate compounds, and can be obtained by making hydroxyalkyl (meth)acrylates Acrylic esters are polymerized with monomers including acrylonitrile and (meth)acrylic esters as polymerizable monomers for the synthesis of acrylic polyols, and thus the resulting adhesive has excellent initial resistance to film upon coating. Tack, initial tack after cure, and high temperature adhesion, also has excellent hydrolysis resistance, and has a satisfactory overall balance. Therefore, the adhesives of Examples are suitable as adhesive...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com