Ceramic Copper Circuit Board And Semiconductor Device Employing Same

A technology for circuit substrates and ceramic substrates, which is applied in semiconductor devices, semiconductor/solid-state device components, and improvement of metal adhesion on insulating substrates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~11、 comparative example 1~9

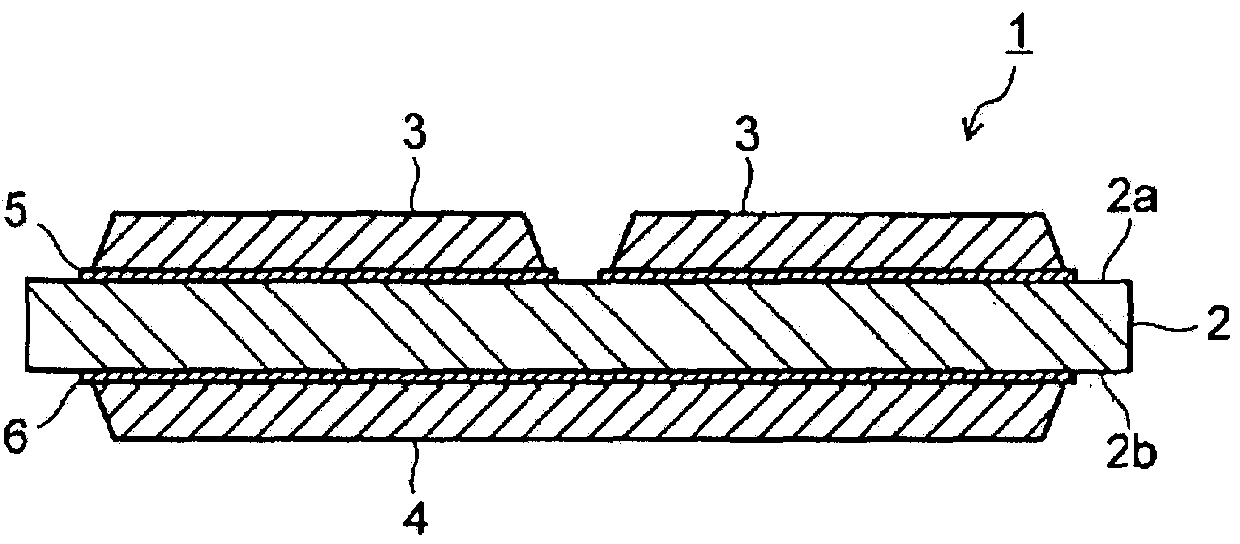

[0045] As the ceramic substrate, a silicon nitride substrate with a thickness of 0.635mm (thermal conductivity: 90W / m·K, three-point bending strength: 730MPa) and an aluminum nitride substrate with a thickness of 0.635mm (thermal conductivity: 180W / m·K, three-point bending strength: 400MPa), an alumina substrate with a thickness of 0.635mm (thermal conductivity: 15W / m·K, three-point bending strength: 500MPa). The shape of the ceramic substrate is uniformly 50 mm long x 30 mm wide.

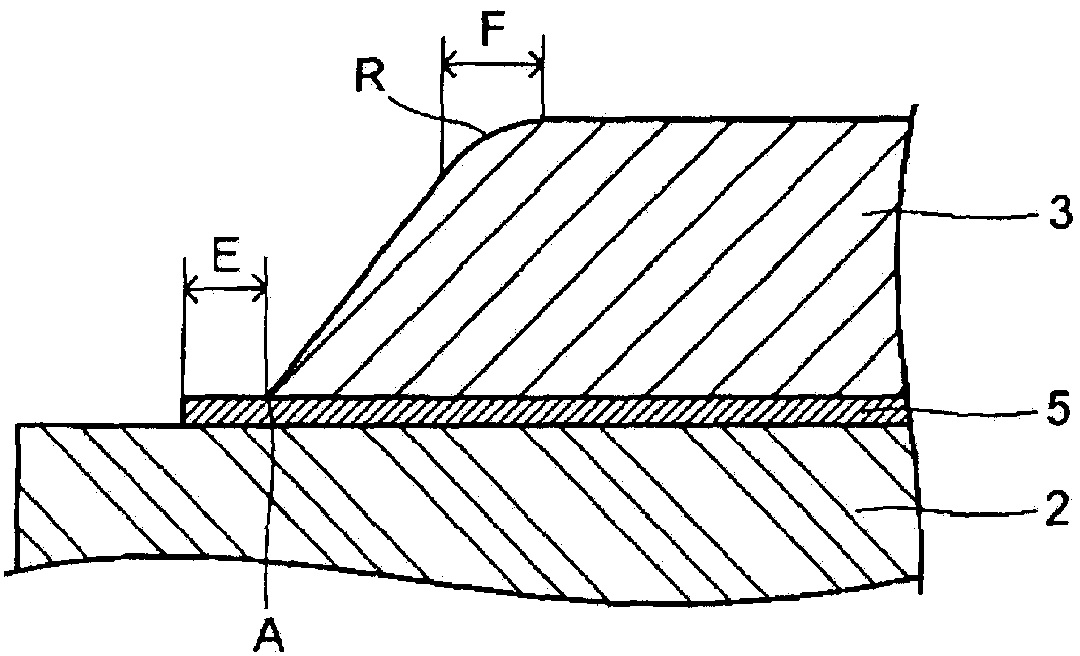

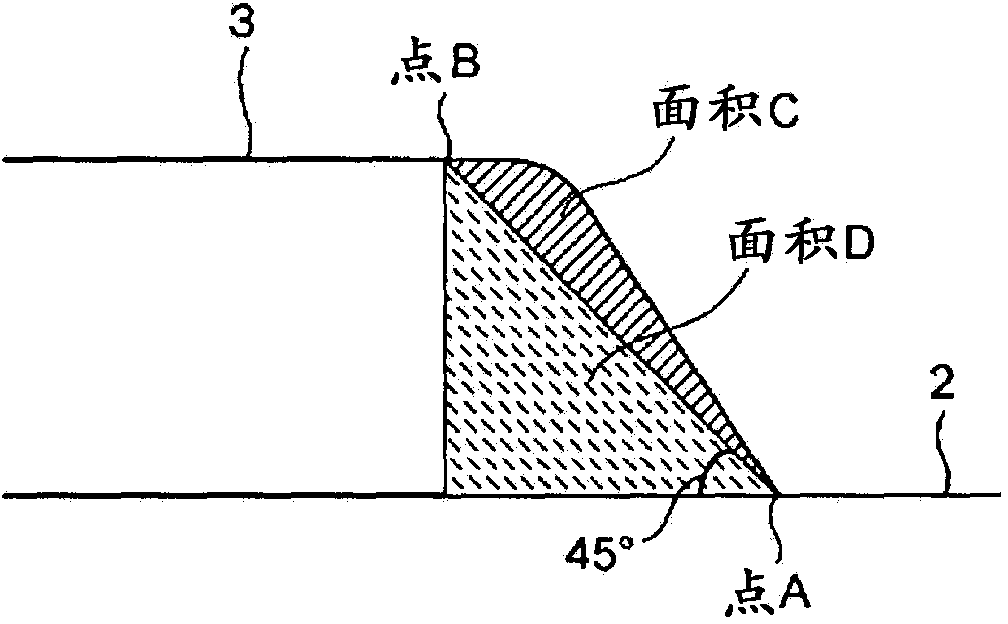

[0046] Next, the active metal solder material having the composition shown in Table 1 was prepared and pasted, and then coated on the ceramic substrate. The coating thickness of the active metal solder paste is shown in Table 1. Next, a copper plate (oxygen-free copper plate) having a thickness of 0.3 mm was prepared. The shape of the copper plates is uniformly 45 mm in length x 25 mm in width. In Examples 1 to 9, a copper plate having a thickness of 0.3 mm was used, and in Examples 10 to 11, a cop...

Embodiment 12~13

[0059] The ceramic copper circuit board of Example 9 was referred to as Example 12, and the ceramic copper circuit board obtained by changing the thickness of the copper plate of the ceramic copper circuit board of Example 9 to 0.5 mm was referred to as Example 13. For the ceramic copper circuit board of Example 12 and Example 13, under condition 2 (1 cycle: -40°C×30 minutes→room temperature (25°C)×10 minutes→175°C×30 minutes→room temperature (25°C)× 10 minutes) TCT was performed, and the number of cycles in which cracks occurred in the ceramic substrate was investigated. The results are shown in Table 4.

[0060] [Table 4]

[0061]

[0062] It can be seen from Table 4 that the ceramic copper circuit board of the example also has a durability of 6000 cycles or more for TCT with a maximum temperature exceeding 170°C.

Embodiment 14~18

[0064] The following substrate was prepared as a ceramic substrate. The ceramic substrate 1 is a silicon nitride substrate with a thickness of 0.320 mm (thermal conductivity: 93 W / m·K, three-point bending strength: 700 MPa). The ceramic substrate 2 is a silicon nitride substrate with a thickness of 0.320 mm (thermal conductivity: 100 W / m·K, three-point bending strength: 600 MPa). The ceramic substrate 3 is an aluminum nitride substrate having a thickness of 0.635 mm (thermal conductivity: 200 W / m·K, three-point bending strength: 320 MPa). The ceramic substrate 4 is an alumina substrate (thermal conductivity: 12 W / m·K, three-point bending strength: 400 MPa) with a plate thickness of 0.635 mm. In addition, the shape of the ceramic substrate is uniformly 50 mm in length × 30 mm in width.

[0065] Next, the active metal solder material of the composition shown in Table 5 was prepared and paste, and printed on the ceramic substrate and applied. A copper plate with a length of 45 mm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com