Grass seed pelleting process

A technology of pelleting and seeding, applied in the field of forage seed pelleting technology, can solve the problems of pelleting seed mechanism formula, unreasonable water content, poor adaptability, and unsatisfactory granulation shape, etc., and achieve the solution of pill coating Seed pesticide residues, increase seed germination rate, suitable for mechanical operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1 Grass seed pelletization

[0029] 1 Matrix formulation and preparation

[0030] 1.1 Matrix formulation

[0031] Diatomite 25kg, talc powder 15kg, vermiculite powder 15kg, peat 5kg, bentonite 20kg, urea formaldehyde 10kg, calcium superphosphate 5kg, humic acid 3kg, superabsorbent resin 2kg.

[0032] 1.2 Preparation of matrix

[0033] The above ingredients are mixed and extruded by a granulating extruder to form a columnar granular matrix with a diameter of less than 4mm and a length of 10mm.

[0034] 2 Selection and screening of forage seeds

[0035] Choose Elymus chinensis seeds, the seed purity is greater than 95%, and the germination rate is above 85%.

[0036] 3 Preparation of forage seed pellets

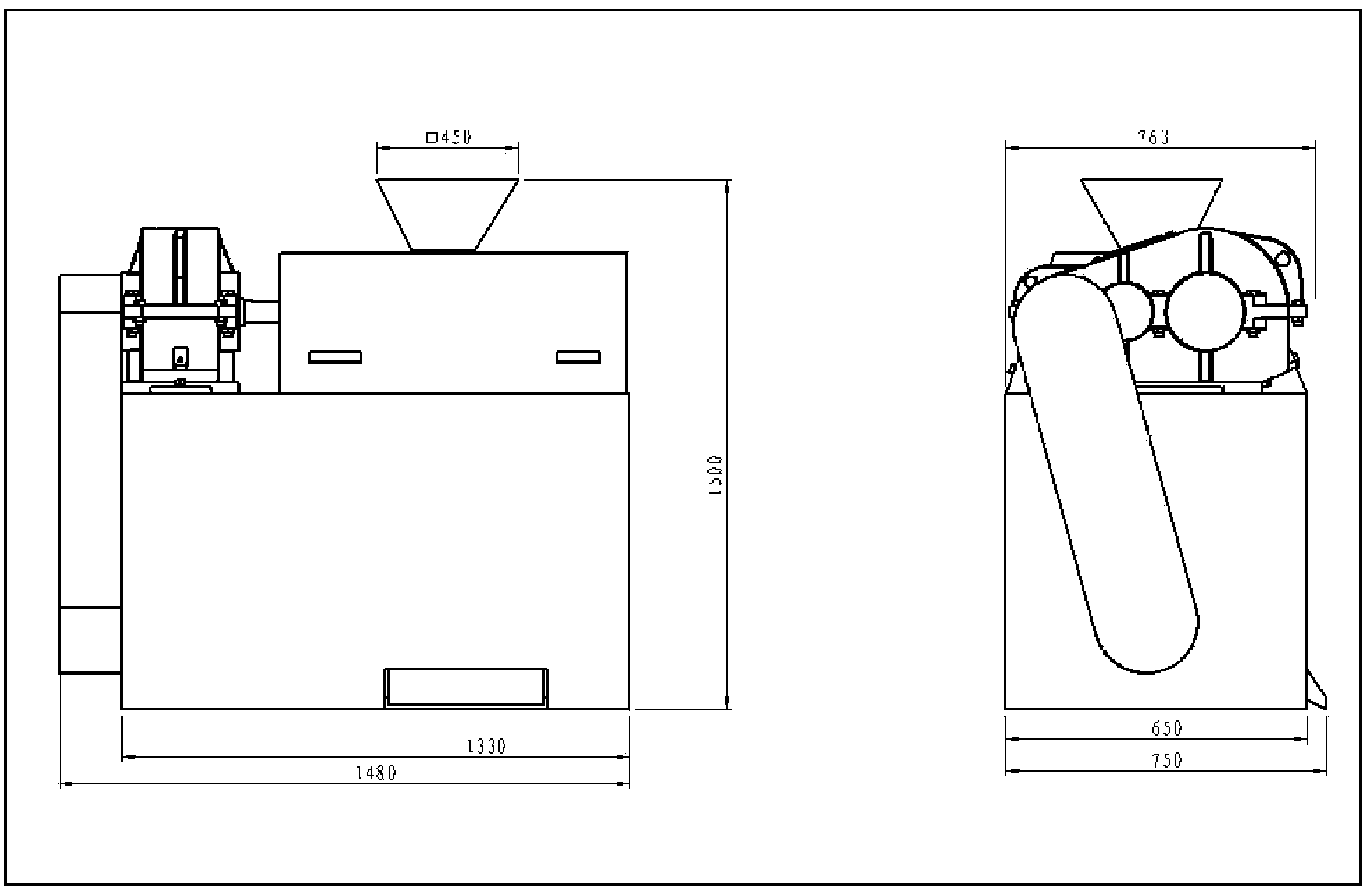

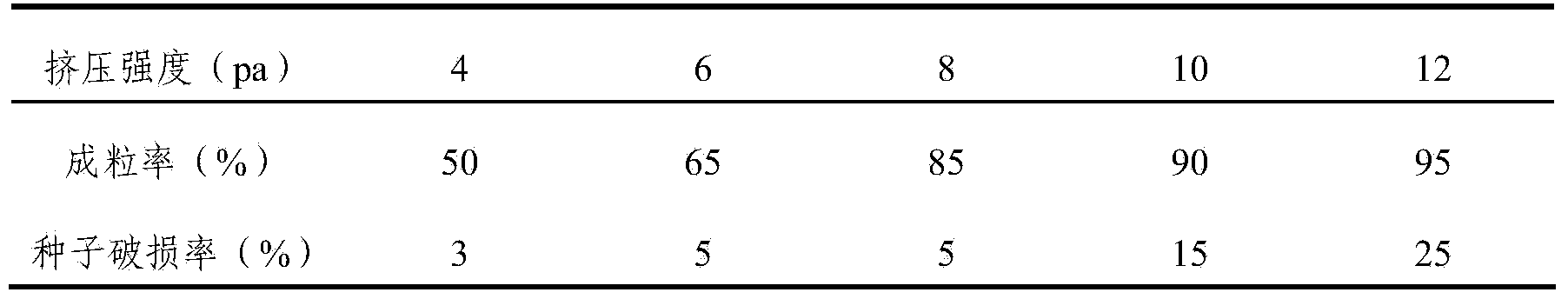

[0037] The prepared matrix is mixed with the screened forage seeds at a ratio of 1:100, and then a pair of roller extrusion granulators (DGZ-15 type, such as figure 2 Shown) extruded and granulated materials (grass seeds and columnar granular matrix) ...

Embodiment 2

[0038] Embodiment 2 Grass seed pelletization

[0039] 1 Matrix formulation and preparation

[0040] 1.1 Matrix formulation

[0041] 20kg of diatomite, 20kg of talc powder, 10kg of vermiculite powder, 5kg of peat, 15kg of bentonite, 10kg of urea-formaldehyde, 3kg of superphosphate, 5kg of humic acid, and 2kg of superabsorbent resin.

[0042] 1.2 Preparation of matrix

[0043] The above ingredients are mixed and extruded by a granulating extruder to form a columnar granular matrix with a diameter of less than 4mm and a length of 5mm.

[0044] 2 Selection and screening of forage seeds

[0045] Choose the seeds of Agrocybe spp., the seed purity is greater than 95%, and the germination rate is above 85%.

[0046] 3 Preparation of forage seed pellets

[0047] The prepared matrix is mixed with the screened forage seeds in a ratio of 1.5:150, and then the material (grass seeds and columnar granular matrix) extruded and granulated with a pair of roller extrusion granulators (DGZ...

Embodiment 3

[0048] Embodiment 3 Grass seed pelletization

[0049] 1 Matrix formulation and preparation

[0050] 1.1 Matrix formulation

[0051] 30kg of diatomite, 10kg of talc powder, 20kg of vermiculite powder, 2kg of peat, 25kg of bentonite, 5kg of urea-formaldehyde, 5kg of superphosphate, 3kg of humic acid, and 5kg of superabsorbent resin.

[0052] 1.2 Preparation of matrix

[0053] The above ingredients are mixed and extruded by a granulating extruder to form a columnar granular matrix with a diameter of less than 4mm and a length of 15mm.

[0054] 2 Selection and screening of forage seeds

[0055] Choose the seeds of awnless brome, the seed purity is greater than 95%, and the germination rate is above 85%.

[0056] 3 Preparation of forage seed pellets

[0057]The prepared matrix is mixed with the screened forage seeds in a ratio of 2:150, and then the material (grass seeds and columnar granular matrix) extruded and granulated with a pair of roller extrusion granulators (DGZ-15...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com