Protective film and preparation method thereof

A technology of protective film and protective film, which is applied in the direction of chemical instruments and methods, film/sheet adhesives, coatings, etc., and can solve the problem of low hardness of protective film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

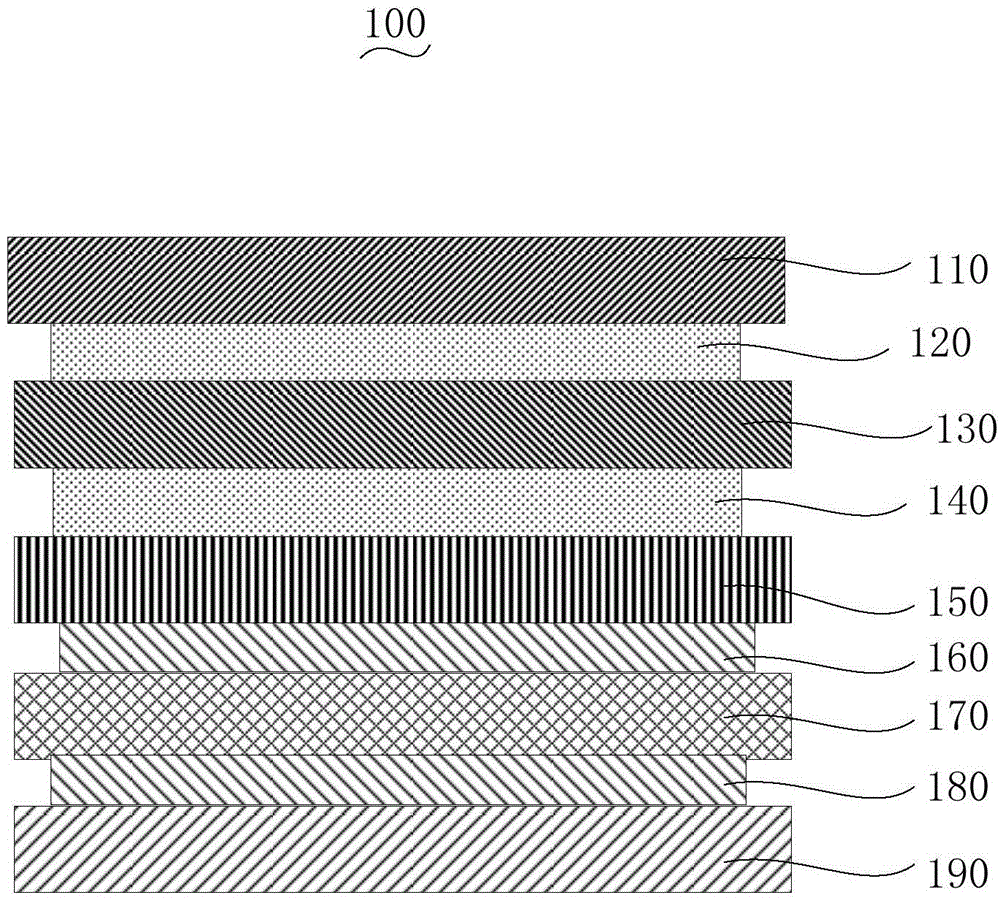

[0051] The preparation method of the protective film of an embodiment, comprises the steps:

[0052] Step S210 , sequentially coating one surface of the main film layer 150 to prepare the first softening layer 140 and the first hardening layer 130 .

[0053] The material of the main film layer 150 is polyethylene terephthalate (PET).

[0054] Preferably, the thickness of the main film layer 150 is 50 μm˜300 μm.

[0055] Preferably, the light transmittance of the main film layer 150 is greater than 90%.

[0056] Preferably, the haze of the main film layer 150 is less than 2%.

[0057] Preferably, before the step of sequentially coating one surface of the main film layer 150 to prepare the first softening layer 140 and the first hardening layer 130 , a step of corona treatment is also included on the two opposite surfaces of the main film layer 150 . Wherein, the first softening layer 140 is disposed on one of the corona-treated surfaces. The corona-treated surface imparts...

Embodiment 1

[0089] (1) One side of the main film layer that has been treated with double-sided corona is coated with a layer of photocurable resin with an antistatic agent, dried and cured, and then coated with a second layer of photocurable resin, and then After drying and curing, the thickness of each dry film is 10 μm to obtain the first softening layer. Wherein, the material of the main film layer is PET, the thickness is 125 μm, the light transmittance is 95%, and the haze of the main film layer is 0.5%. The thickness of the first softening layer is 20 μm, and the material of the first softening layer is a mixture of polyurethane acrylate, epoxy acrylate, polyester acrylate and antistatic agent. In the first softening layer, the mass ratio of polyurethane acrylate, epoxy acrylate and polyester acrylate is 4:3:3, and the antistatic agent is diisobutylene-maleic acid disodium salt, polyethylene polyamine and polyether A mixture of esters, the mass ratio of diisobutylene-maleic acid di...

Embodiment 2

[0095] (1) One side of the main film layer that has been treated with double-sided corona is coated with a layer of photocurable resin with an antistatic agent, dried and cured, and then coated with a second layer of photocurable resin, and then After drying and curing, the thickness of each dry film is 9 μm to obtain the first softening layer. Wherein, the material of the main film layer is PET, the thickness is 100 μm, the light transmittance is 93%, and the haze of the main film layer is 0.5%. The thickness of the first softening layer is 18 μm, and the material of the first softening layer is a mixture of polyurethane acrylate, epoxy acrylate, polyester acrylate and antistatic agent. In the first softening layer, the mass ratio of polyurethane acrylate, epoxy acrylate and polyester acrylate is 3:3:4, and the antistatic agent is octadecyl dimethyl hydroxyethyl quaternary ammonium nitrate, antistatic The mass ratio of the agent to the total mass of polyurethane acrylate, ep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com