Hot rolled ribbed steel bar with yield-to-tensile ratio of less than or equal to 0.8 and Rel of more than or equal to 600MPa, and production method

A technology of hot-rolled ribbed steel bars and yield strength ratio, which is applied in the field of construction steel bars and its production, can solve the problems of insufficient use of vanadium, etc., and achieve excellent seismic performance and excellent welding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

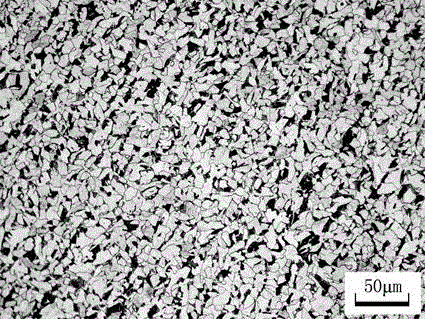

Image

Examples

Embodiment Construction

[0030] The present invention is described in detail below:

[0031] Except that the casting slab size of embodiment 3 is 200 * 230mm, all adopt the square billet of 200 * 200mm

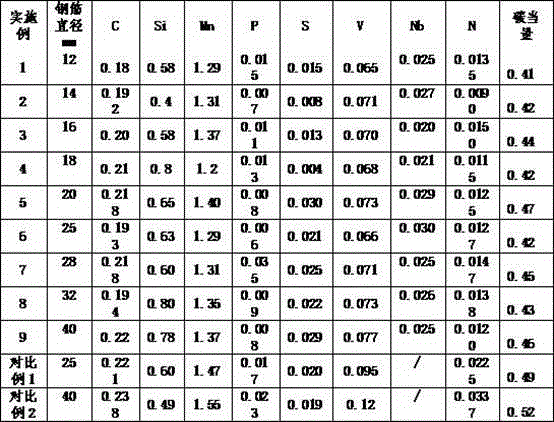

[0032] Table 1 is the value list of each embodiment of the present invention and comparative examples;

[0033] Table 2 is the main process parameter list of each embodiment of the present invention and comparative example;

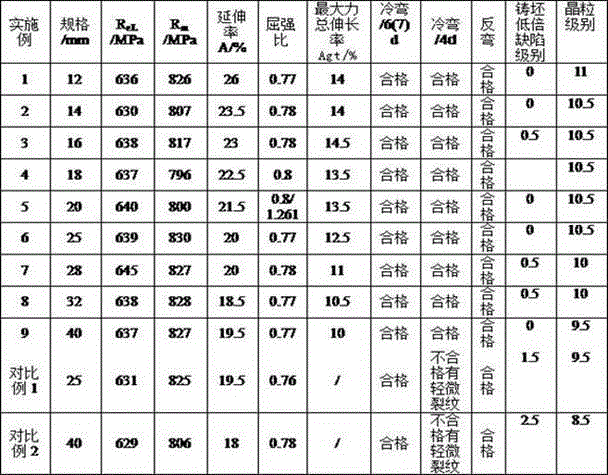

[0034] Table 3 is a list of the performance tests of the various embodiments of the present invention and comparative examples.

[0035] Each embodiment of the present invention is produced according to the following steps:

[0036] 1) Conventional smelting and slab casting: Nitrogen addition adopts the conventional method of adding nitrogen-containing alloys; the tapping temperature is 1680-1700°C; the casting slab casting speed is not higher than 1.8m / min;

[0037] 2) Stack and cool the billets to room temperature; water cooling is prohibited;

[0038] 3) To heat the billet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com