An air spring-maglev hybrid vibration isolator

A hybrid vibration isolator and air spring technology, which is applied in the direction of spring/shock absorber, vibration suppression adjustment, non-rotational vibration suppression, etc., can solve the unfavorable linearization between output electromagnetic force and current of unilateral electromagnetic actuator The spring vibration isolation foundation cannot take into account the horizontal and vertical directions, and the vibration isolation of the ship's power plant is not applicable, etc., to achieve excellent high-frequency vibration isolation performance, convenient installation and disassembly maintenance, and compact structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] specific implementation plan

[0032] The air spring-magnetic suspension hybrid vibration isolator provided by the present invention highly integrates the differential magnetic suspension vibration isolator and the air spring, fully combines the advantages of the air spring and the magnetic suspension vibration isolator, realizes broadband vibration isolation, and has fast response, It has the characteristics of high reliability, compact structure, large carrying capacity and convenient maintenance.

[0033] The present invention will be further described below in conjunction with the embodiments and accompanying drawings, but is not limited to the content described below.

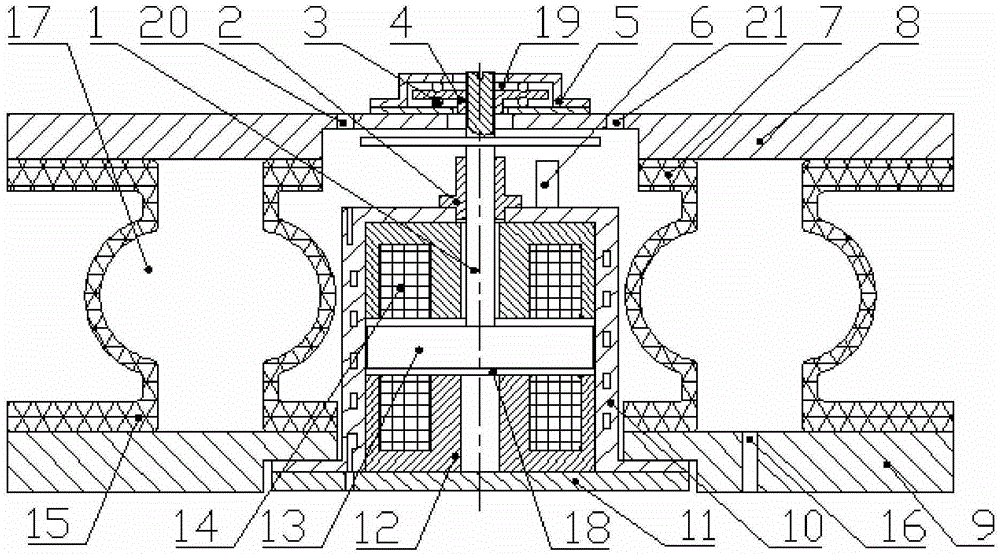

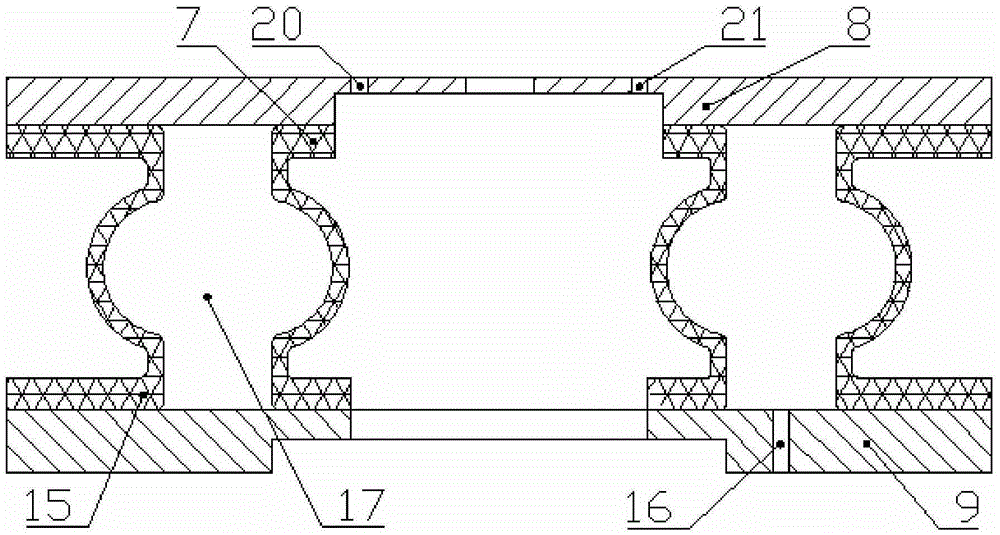

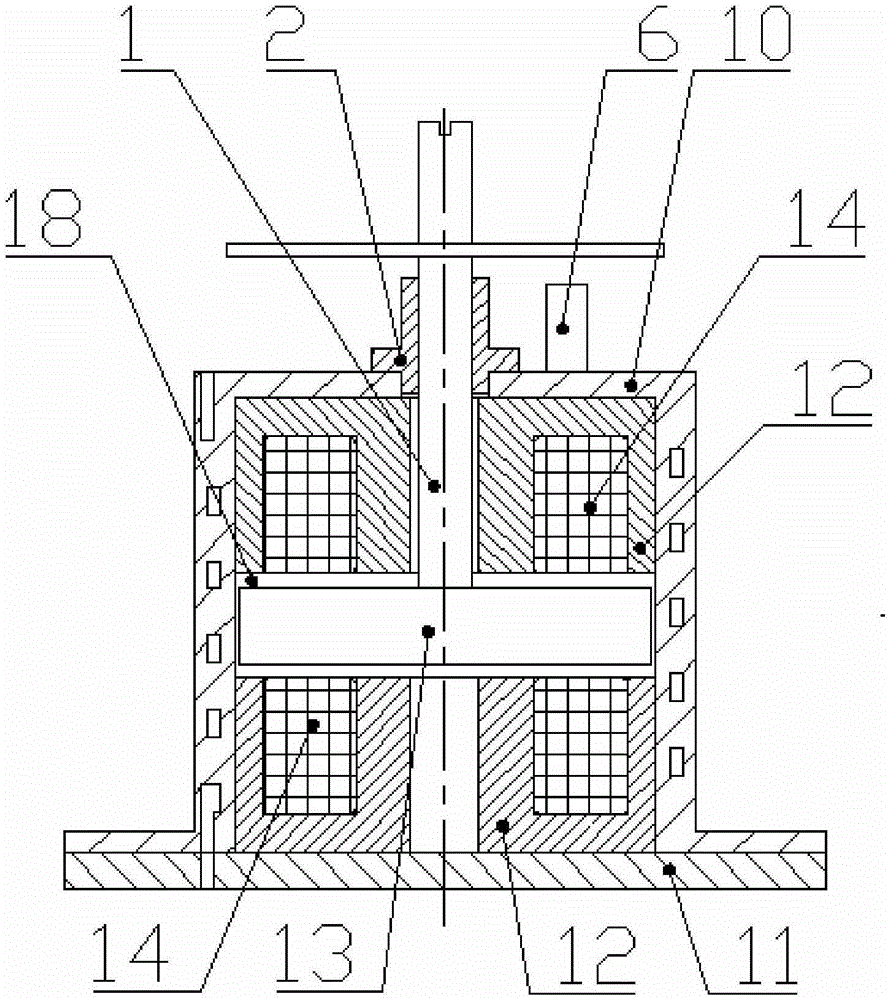

[0034] The air spring-maglev hybrid vibration isolator provided by the present invention has a structure such as Figure 1 to Figure 4 As shown, it includes an air spring 17 , a magnetic suspension vibration isolator 18 and a connecting part 19 . The air spring 17 is composed of an upper cover pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com