Portable area array imaging system based on X-ray linear array scanning

A linear array scanning and area array imaging technology, applied in the field of radiation imaging, can solve the problems of large volume and weight, unsuitable for industrial construction sites, use, etc., and achieves the effects of good adaptability, compact structure, and easy disassembly and assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

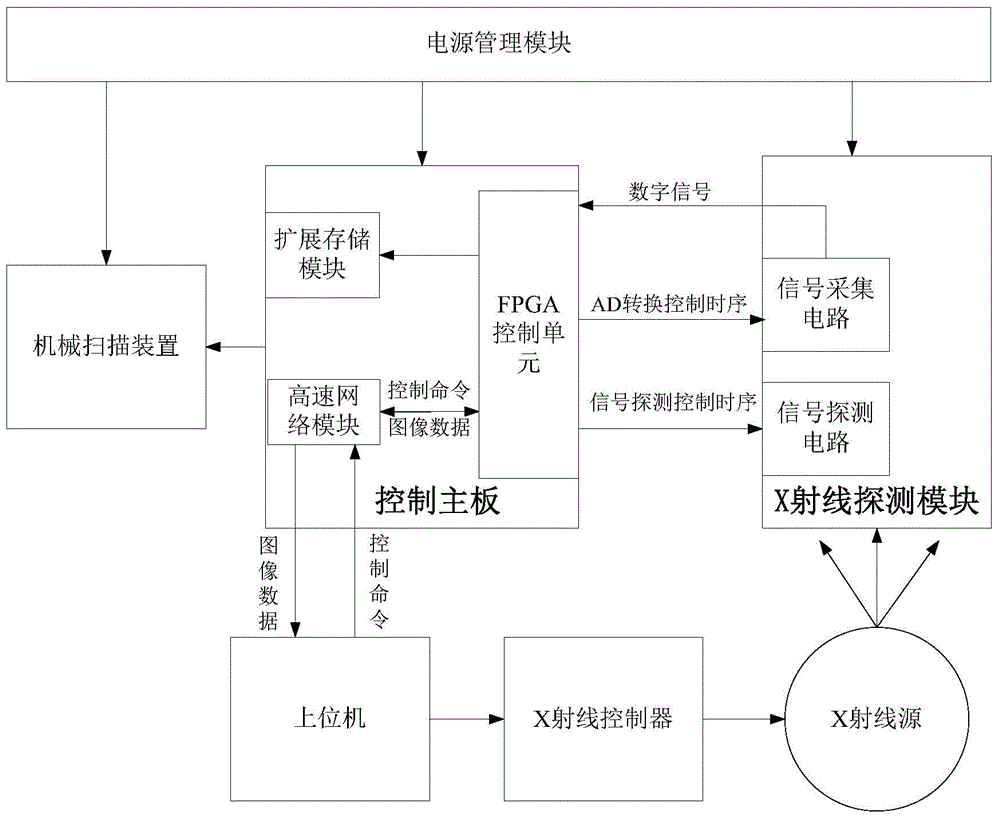

[0050] Such as figure 1 , 2 As shown, the portable area scan imaging system based on X-ray line scan includes:

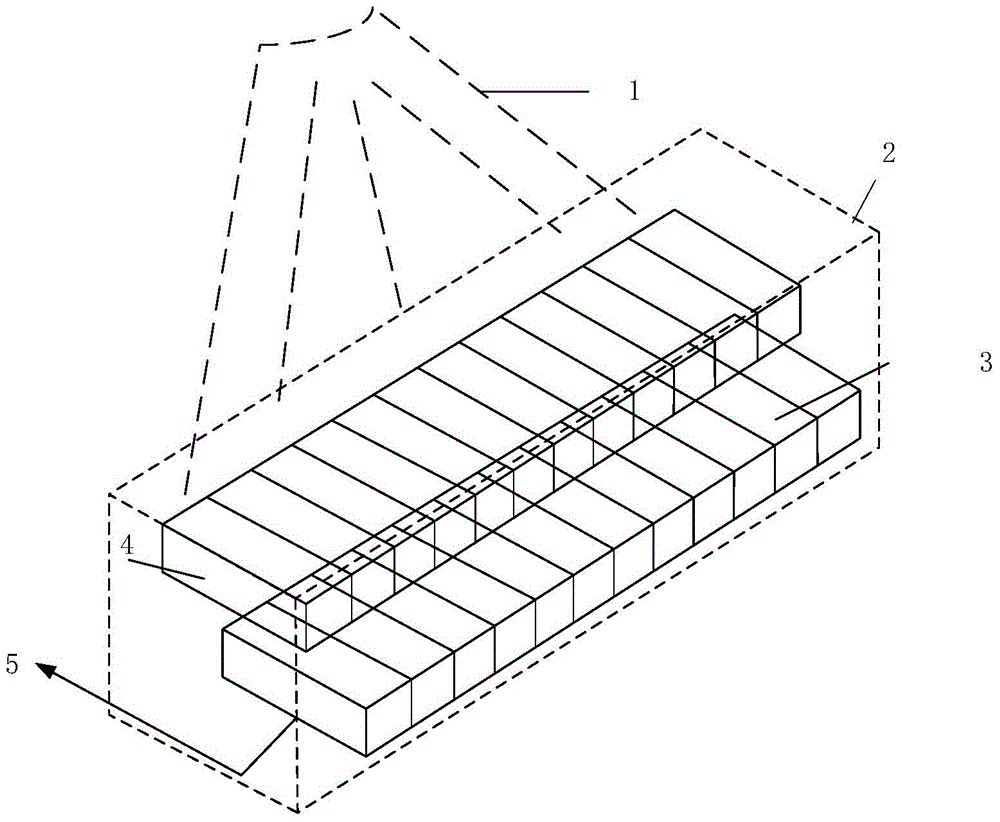

[0051] The X-ray detection module 8 installed on the mechanical scanning device corresponding to the X-ray generator, the X-ray detection module 8 is used to receive the information after the X-ray 1 generated by the X-ray generator passes through the measured object 11, wherein, The intensity distribution of the X-ray 1 after passing through the measured object 11 carries the information of the measured object 11 .

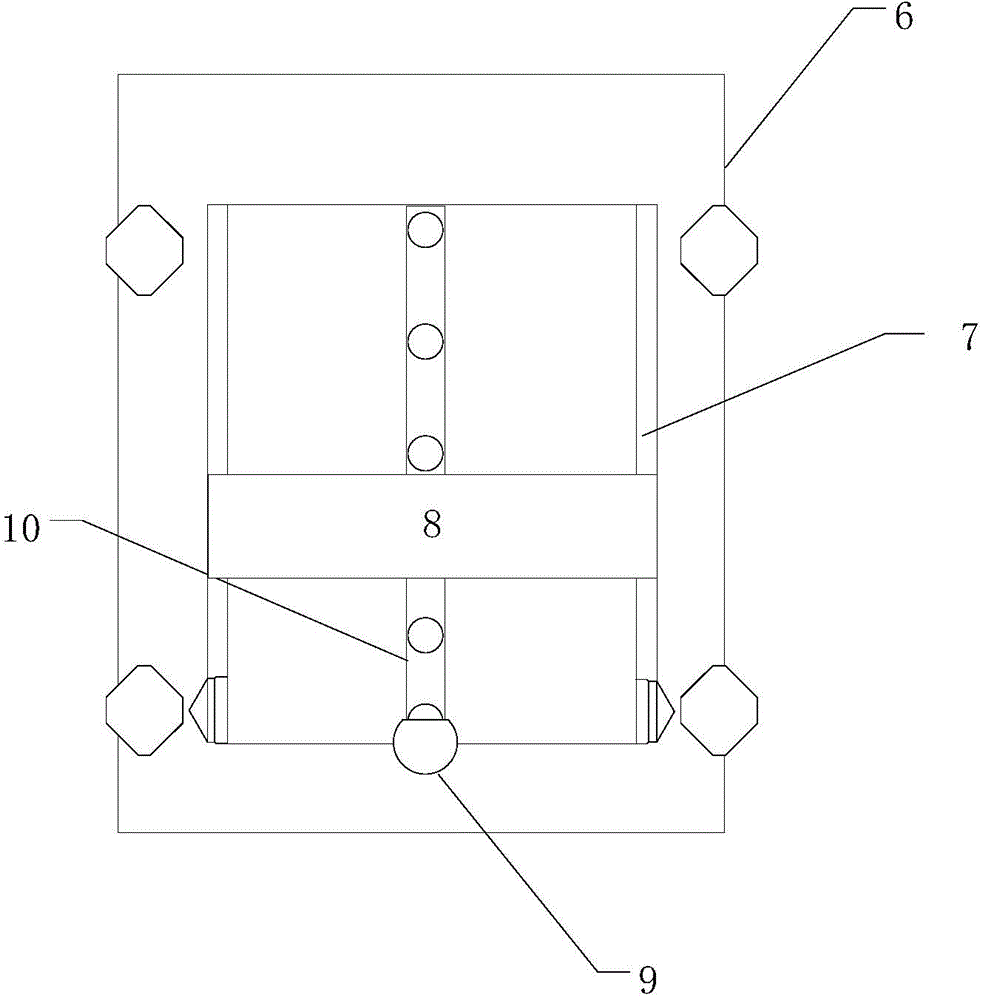

[0052] The structural schematic diagram of the mechanical device for realizing planar mobile scanning is attached image 3 As shown, the entire scanning device mainly includes a scanning frame 6, a stepping motor 9, a lead screw 10, a linear guide 7 and the like. The X-ray detection module 8 is fixed on the moving slider of the linear guide rail 7 and the moving slider of the lead screw 10, and the moving slider of the leading screw 10 and the movi...

Embodiment 2

[0069] Different from Embodiment 1, the mechanical device for completing the mobile scanning of the curved surface is as attached Figure 4 As shown, the whole scanning device includes parts such as tank chain 14, stepper motor 9, drive gear 12, transmission chain 13. The tank chain 14 can be bent and shaped accordingly according to the shape of the measured object 11 , and the X-ray detection module 8 is fixed on the transmission chain 13 at both ends of the tank chain 14 . When the stepping motor 9 drives the gear 12 to drive the transmission chain 13 to move, the X-ray detection module 8 moves accordingly to complete the curved surface scanning. The reciprocating motion of the X-ray detection module 8 along the curved surface can be realized by controlling the forward and reverse rotation of the stepping motor.

Embodiment 3

[0071] Different from Embodiment 1, the mechanical device for curved surface mobile scanning is as attached Figure 5 As shown, it adopts the structure of a crawling trolley 15, and the magnetic small wheel 17 of the crawling trolley 15 enables it to be adsorbed on the inner or outer surface of the object 11 to be measured. The X-ray detection module 8, the control board and the power supply 16 are all integrated in the crawling vehicle. Car 15 on. The crawling trolley 15 can move smoothly along the surface of the measured object 11 after receiving the scanning command from the host computer to complete scanning and imaging. This trolley-structured scanning device is not limited by the size of the measured object 11, and has better adaptability to various industrial construction sites.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com