Method for analyzing and determining the content of antioxidant pep-36 by high performance liquid chromatography

A high-performance liquid chromatography, PEP-36 technology, applied in the field of high-performance liquid chromatography analysis and determination of antioxidant PEP-36 content, can solve problems such as the limit and detection method of unloaded antioxidant PEP-36, and achieve Strong specificity, good separation, and ensure the effect of quality control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

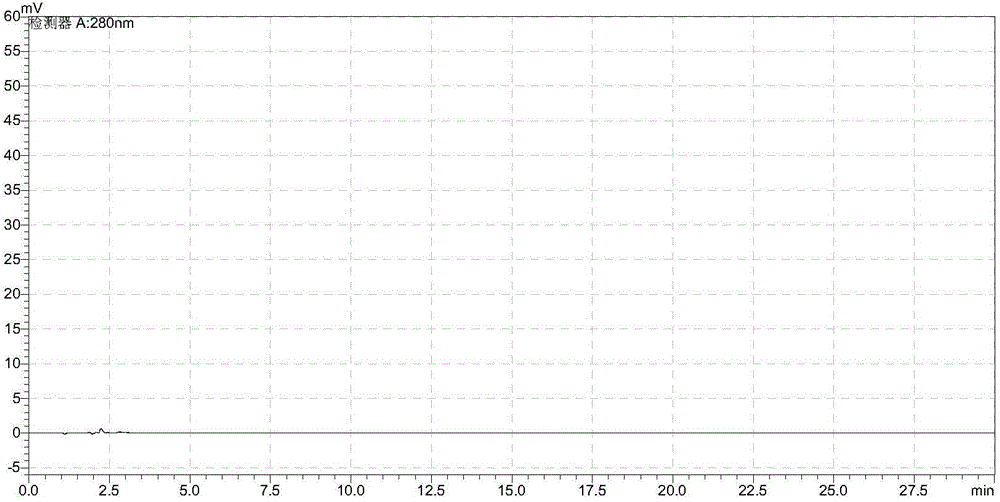

[0032] Instruments and Conditions

[0033] Shimadzu 20A high performance liquid chromatography; column: Shimadzu InertsilODS-3, 250×4.6mm, 5μm; UV detection wavelength: 200nm; column with octadecylsilane bonded silica gel; mobile phase: acetonitrile- Tetrahydrofuran-water, the volume ratio of acetonitrile, tetrahydrofuran and water is 70:10:20; column temperature: 25°C; mobile phase flow rate: 0.8ml / min; injection volume: 10μl.

[0034] The volume ratio of toluene and methanol in toluene-methanol solvent is 1:1.

[0035] Experimental procedure

[0036] (1) Take 5g of the polypropylene interface and place it in a borosilicate glass bottle with a ground glass stopper. Add 50ml of toluene and boil under reflux for 1 hour;

[0037] (2) After reflux finishes, keep stirring and cooling and add 50ml methanol;

[0038] (3) filter through No. 4 sand core funnel, and filter again with the toluene-methanol solution washing flask, all filtrates are transferred in the 500ml measuring b...

Embodiment 2

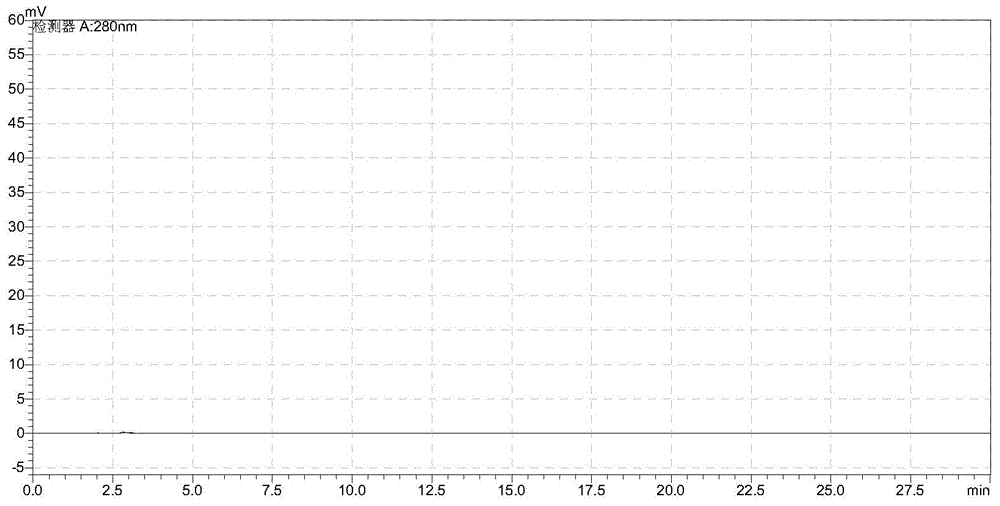

[0043] Instruments and Conditions

[0044] Shimadzu 20A high performance liquid chromatography; column: Shimadzu InertsilODS-3, 250×4.6mm, 5μm; UV detection wavelength: 240nm; column with octadecylsilane bonded silica gel; mobile phase: acetonitrile- Tetrahydrofuran-water, the volume ratio of acetonitrile, tetrahydrofuran and water is 70:15:15; column temperature: 30°C; flow rate of mobile phase: 0.9ml / min; injection volume: 15μl.

[0045] The volume ratio of toluene and methanol in toluene-methanol solvent is 1:1.

[0046] Experimental procedure

[0047] (1) Take 7g of polypropylene film and place it in a borosilicate glass bottle with a ground glass stopper. Add 70ml of toluene and boil under reflux for 1.5 hours;

[0048] (2) After reflux finishes, keep stirring and cooling and add 70ml methanol;

[0049] (3) filter through No. 4 sand core funnel, and filter again with the toluene-methanol solution washing flask, all filtrates are transferred in the 500ml measuring bott...

Embodiment 3

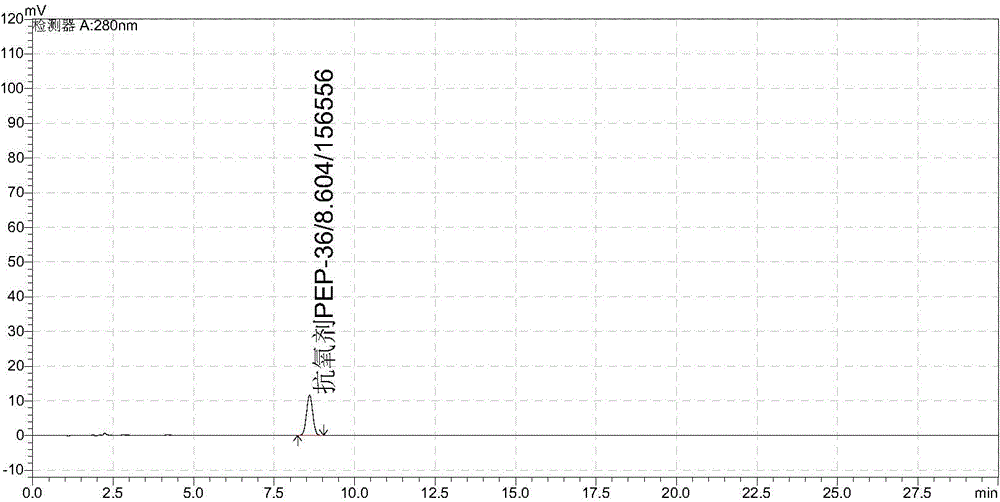

[0054] Instruments and Conditions

[0055] Shimadzu 20A high performance liquid chromatography; column: Shimadzu InertsilODS-3, 250×4.6mm, 5μm; UV detection wavelength: 270nm; column with octadecylsilane bonded silica gel; mobile phase: acetonitrile- Tetrahydrofuran-water, the volume ratio of acetonitrile, tetrahydrofuran and water is 70:15:15; column temperature: 35°C; mobile phase flow rate: 1.1ml / min; injection volume: 15μl.

[0056] The volume ratio of toluene and methanol in toluene-methanol solvent is 1:1.

[0057] Experimental procedure

[0058] (1) Take 8g of polypropylene combination cap and place it in a borosilicate glass bottle with a ground glass stopper. Add 80ml of toluene and boil under reflux for 2 hours;

[0059] (2) After reflux finishes, keep stirring and cooling and add 80ml methanol;

[0060] (3) filter through No. 4 sand core funnel, and filter again with the toluene-methanol solution washing flask, all filtrates are transferred in the 500ml measurin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com