An infrared temperature measurement track inspection robot

A technology of inspection robot and infrared temperature measurement, applied in the direction of two-dimensional position/channel control, etc., can solve the problems of inability to realize all-weather monitoring, unrestricted movement range, easy to touch live equipment by mistake, and achieve unattended The effect of customization, arbitrary continuous working time and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032]The specific embodiment of the present invention will be described in further detail below in conjunction with the drawings, wherein the same symbols in all the drawings represent the same or similar components, and the drawings in the description are in simplified form and are only for understanding the specific structure of the present invention. The following examples are only used to illustrate the technical solutions of the present invention more clearly, but not to limit the protection scope of the present invention.

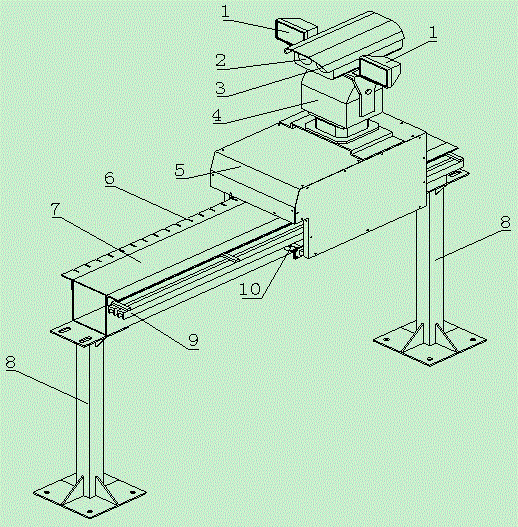

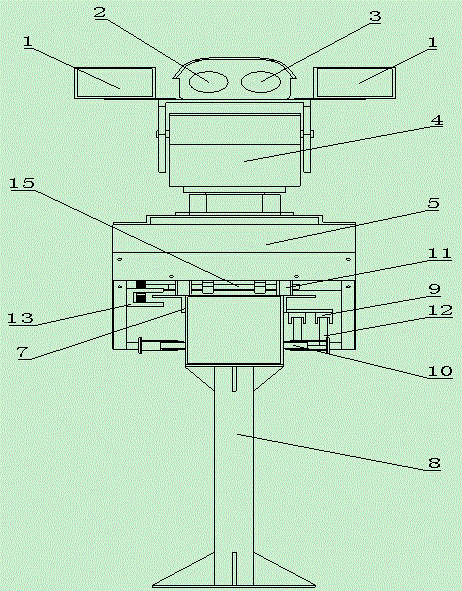

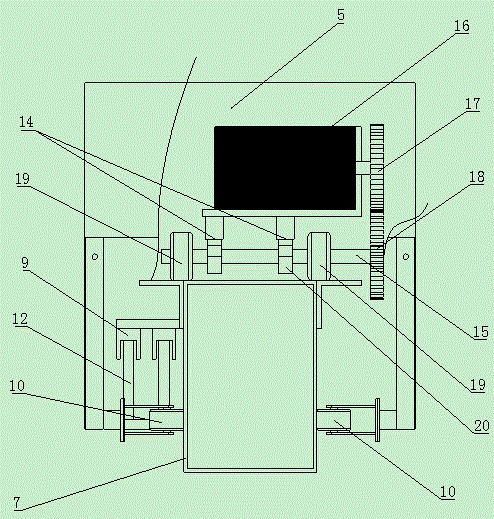

[0033] Such as Figure 1 to Figure 4 As shown, the infrared temperature measurement track inspection robot includes a robot control system, which includes a pan platform 4, a robot control box 5, a track 7, a slide line 9, a collector 12, an infrared photoelectric sensor 13 and a bogie 14, and the bogie The upper surface of the longitudinal beam of 14 is equipped with a robot control box 5, and the upper surface of the robot control box 5 is equipped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com