touch screen

A touch screen and touch electrode technology, which is applied in the input/output process of instruments, electrical digital data processing, and data processing, etc., can solve the problems such as the reduction of the electrical conductivity of the grid-like conductive layer, achieve low resistivity, and avoid scratches. , the effect of reducing the chance of contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The touch screen will be further described below in conjunction with the drawings and specific embodiments.

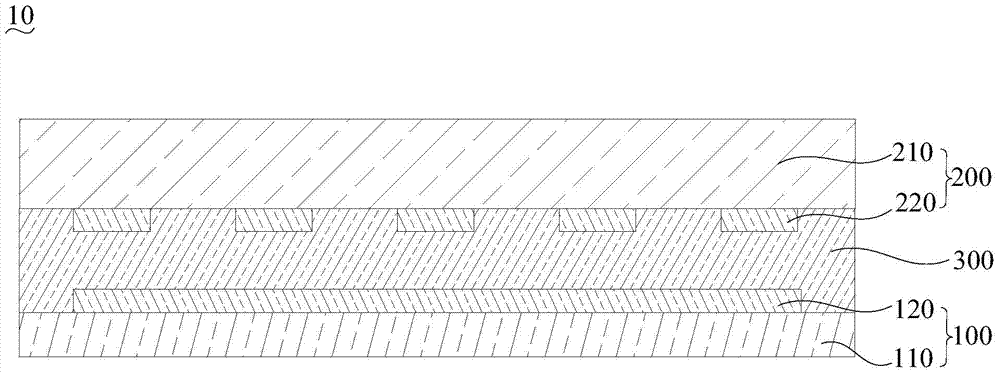

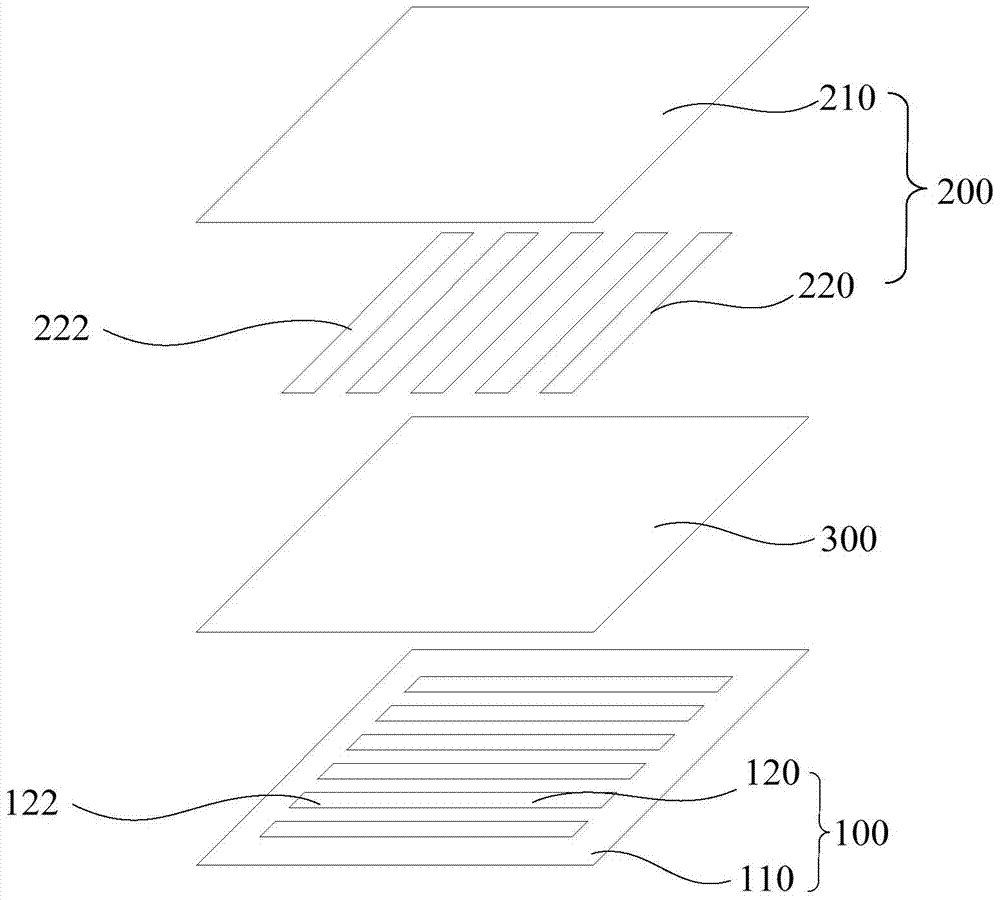

[0034] Such as figure 1 and figure 2 As shown, the touch screen 10 according to one embodiment includes a touch substrate 100 , a protective substrate 200 and a transparent optical adhesive layer 300 .

[0035] The touch control substrate 100 includes a transparent substrate 110 and a first conductive layer 120 .

[0036] The material of the transparent substrate 110 can be glass, polymethyl methacrylate, polycarbonate, polyethylene terephthalate, cycloolefin copolymer or cycloolefin polymer. The thickness of the transparent substrate 110 is 0.02mm˜0.5mm. Further, in this embodiment, after comprehensively considering the processing easiness of the transparent substrate 110 and the overall thickness of the touch screen 10 , the thickness of the transparent substrate 110 is preferably 0.05 mm˜0.2 mm.

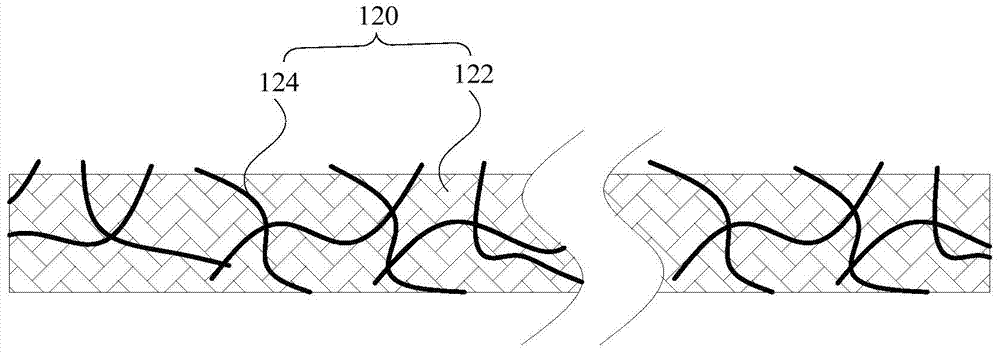

[0037] Such as Figure 1-3 As shown, the first conductiv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com