Polythiophene/ mixed valence metal oxide collaborative conductive slurry and preparation method thereof

A conductive paste, mixed-valence technology, applied in the manufacture of cables/conductors, conductive materials dispersed in non-conductive inorganic materials, circuits, etc. Not easy to color, dark color and other problems, to achieve the effect of good electrical and thermal stability, easy to color, simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

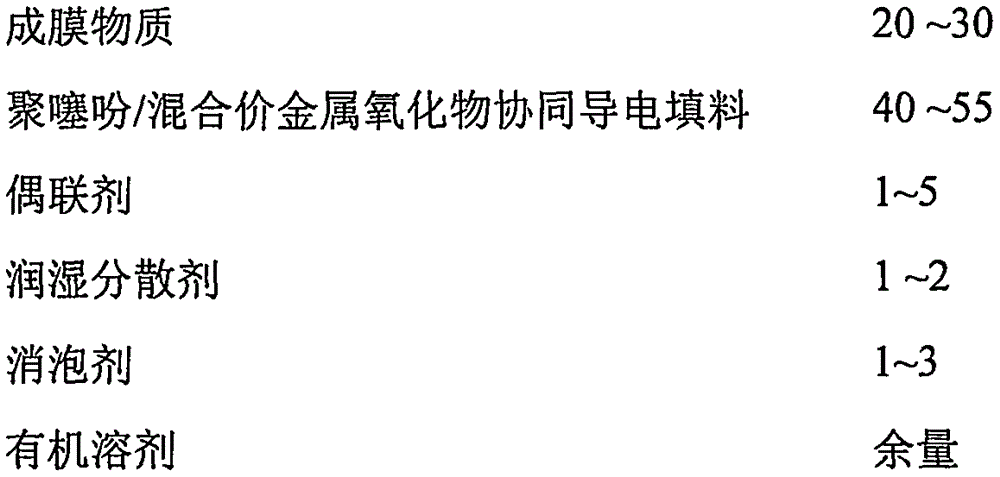

[0035] The basic formula of the conductive paste is:

[0036]

[0037] Stir and disperse the above raw materials in proportion, and pass through a 300-mesh sieve to obtain the finished conductive paste. In the polythiophene / mixed valence metal oxide synergistic conductive filler, the weight ratio of polythiophene to mixed valence metal oxide is 100:1, and when the thickness of the conductive film is 0.1mm, the surface resistance of the conductive film is 5×10 -2 Ω / cm.

Embodiment 2

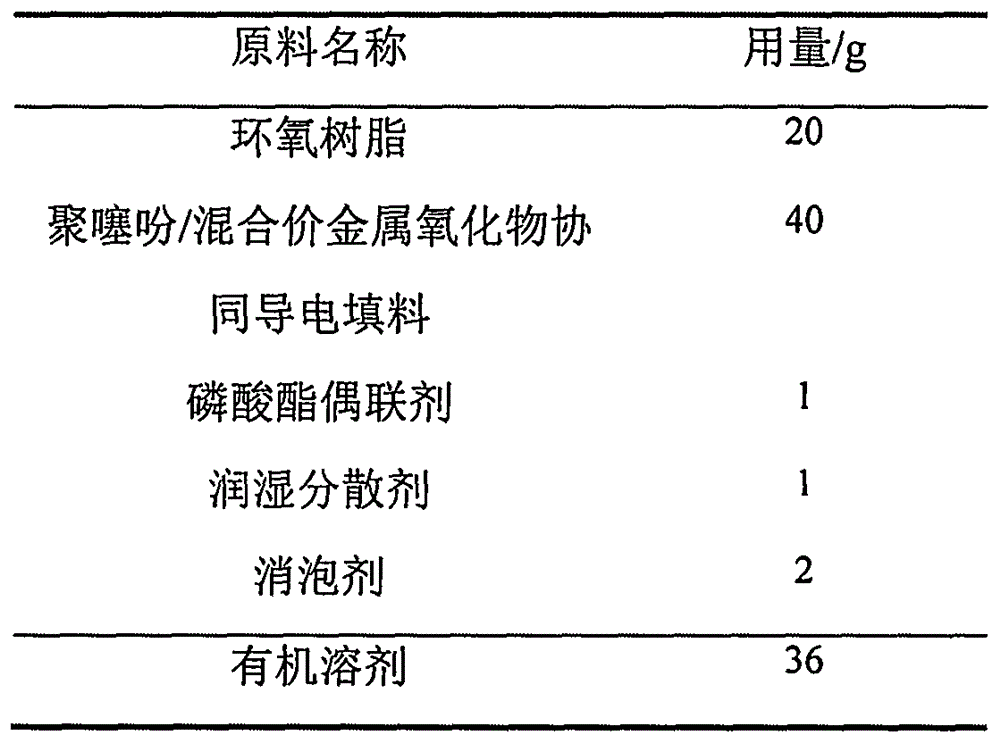

[0039] The basic formula of the conductive paste is:

[0040]

[0041] Stir and disperse the above raw materials in proportion, and pass through a 300-mesh sieve to obtain the finished conductive paste. The weight ratio of polythiophene and mixed valence metal oxide in the polythiophene / mixed valence metal oxide synergistic conductive filler is 100:30, and when the thickness of the conductive film is 0.1mm, the surface resistance of the conductive film is 0.4×10 -2 Ω / cm.

Embodiment 3

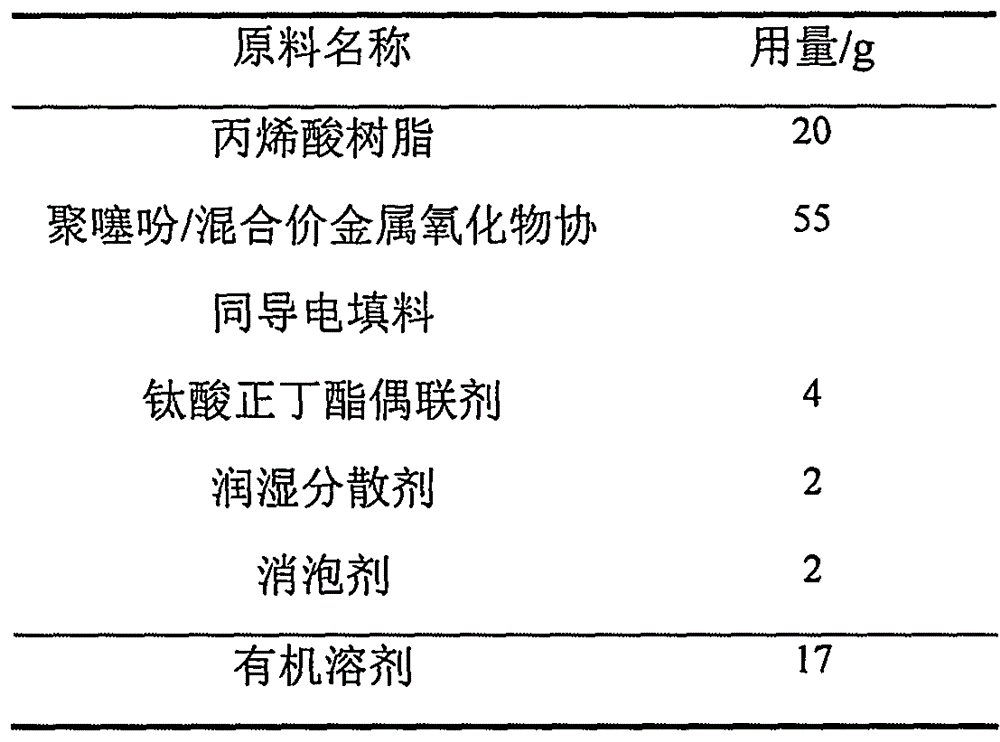

[0043] The basic formula of the conductive paste is:

[0044]

[0045] Stir and disperse the above raw materials according to the proportion, and prepare the finished conductive paste. The weight ratio of polythiophene and mixed valence metal oxide in the polythiophene / mixed valence metal oxide synergistic conductive filler is 100:15, and when the thickness of the conductive film is 0.1mm, the surface resistance of the conductive film is 0.5×10 -2 Ω / cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Surface resistance | aaaaa | aaaaa |

| Surface resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com