Formula and preparation process of belted layer cushion rubber of all-steel radial tire

A radial tire and belt layer technology is applied in the field of rubber compound formulation and rubber compound preparation technology for all-steel radial tire belt layer, which can solve the problem of increased stress deformation, difficulty in processing performance, reduction of rubber compound hardness and definite elongation stress. Small and other problems, to achieve the effect of prolonging the service life, improving economic benefits, and improving the performance of the gasket

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Before introducing the present invention, earlier present situation is briefly described.

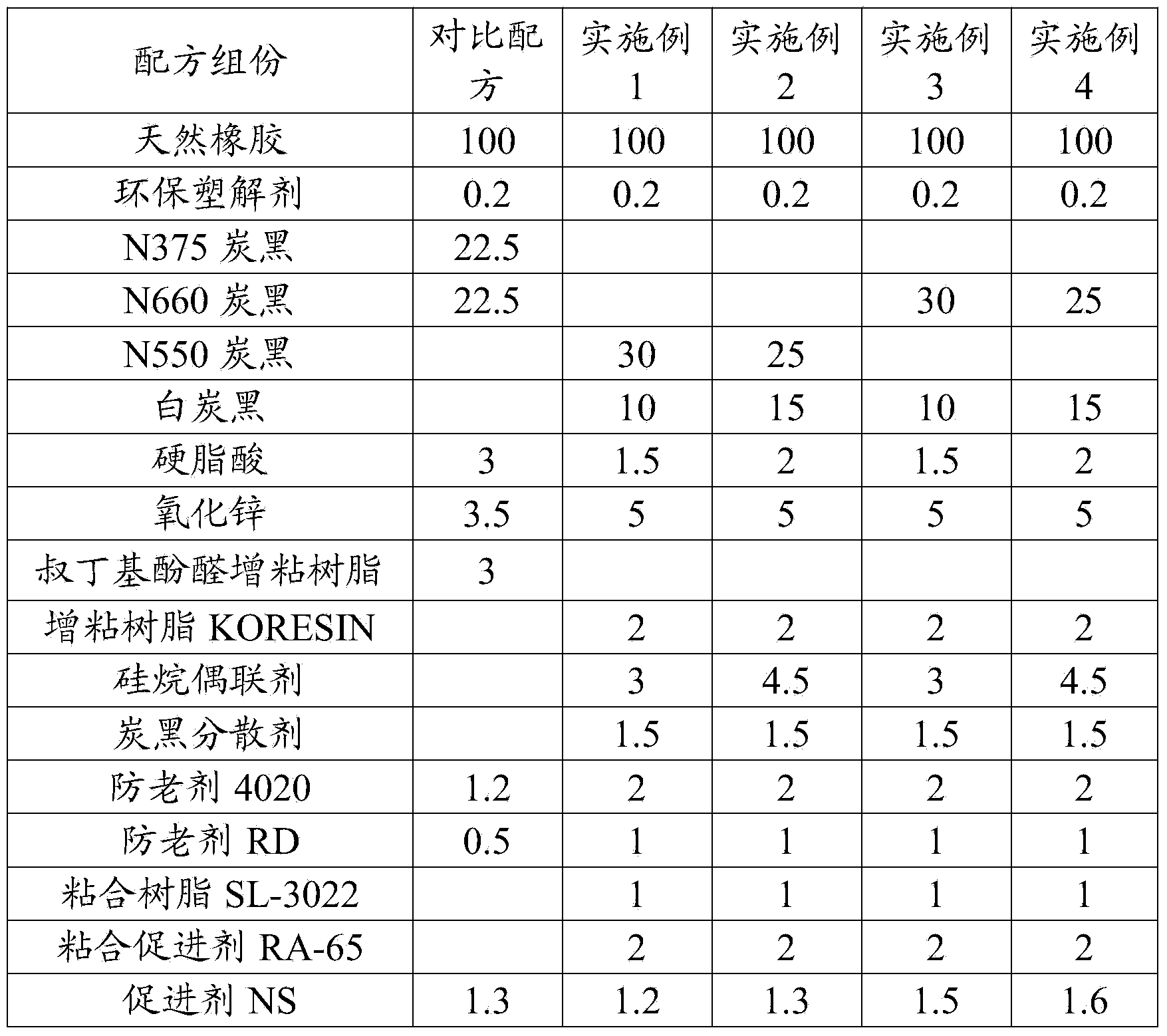

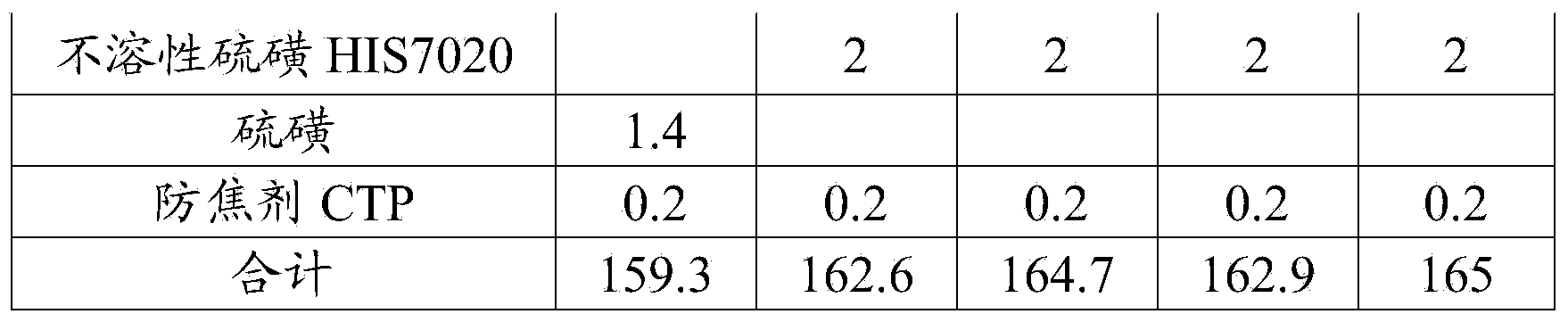

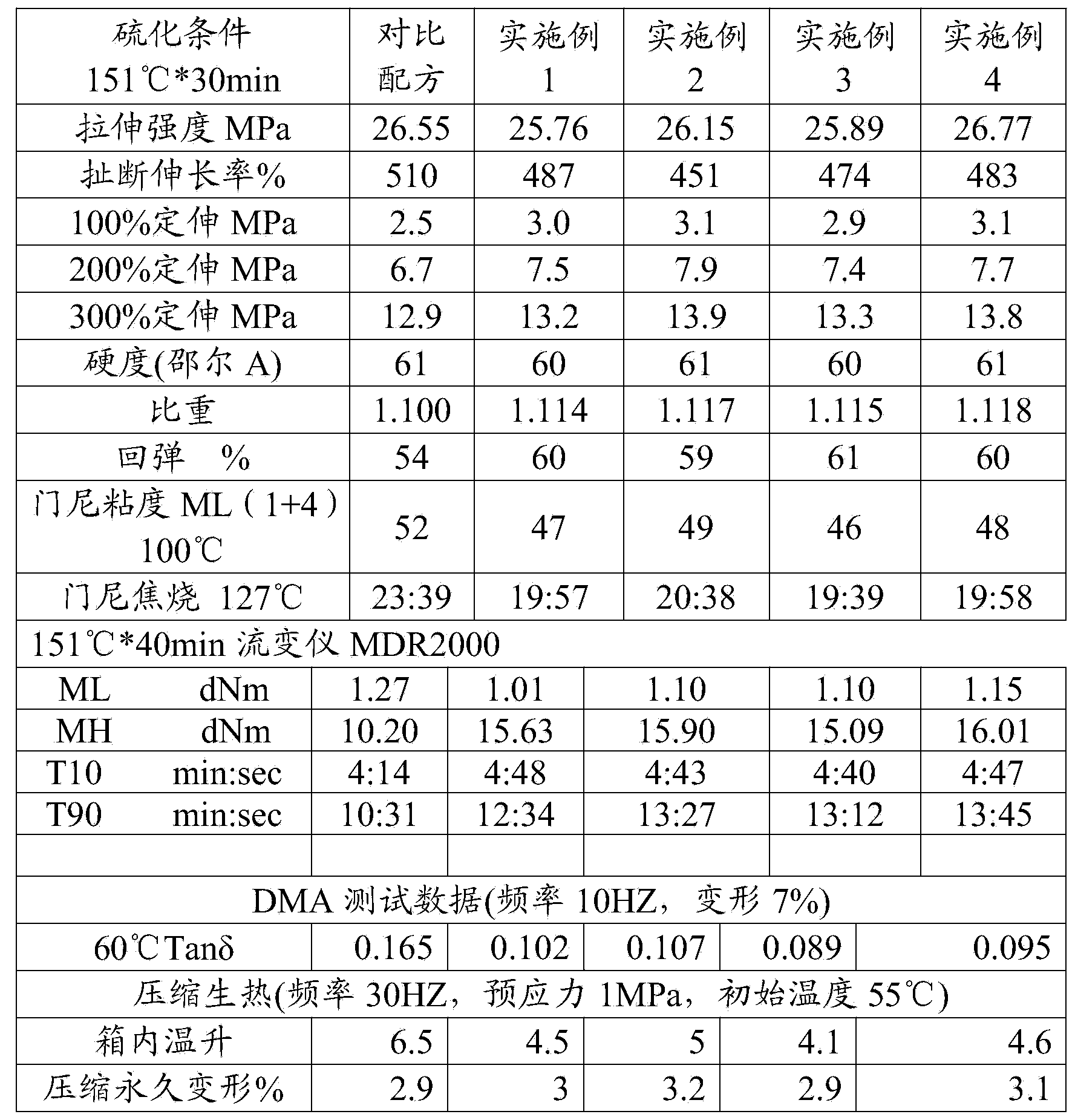

[0010] The reinforcing system in the existing belt pad rubber formula adopts the combination of N375 and N660, the total amount of carbon black is 45 parts, the content is high, the modulus stress of the rubber material is high, but the hysteresis loss is high, the heat generation is large, and the fatigue resistance is poor.

[0011] The amount of anti-aging agent in the existing belt cushion rubber formula is relatively small, with a total amount of 1.7 parts, which is unfavorable for thermal aging resistance and fatigue resistance.

[0012] At present, the formula design of the belt cushion rubber generally contains a certain amount of tackifying resin to ensure the joints of rubber parts and good adhesion with other parts. Usually, tert-butylphenol-formaldehyde tackifying resin is used, and the dosage is 2 parts. About, but because these ordinary tackifying resins will increa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com