A New Type of Tunnel Smooth Excavation Rock Drilling Equipment and Construction Method

A construction method and technology of rock drilling equipment, which are applied in the field of new tunnel smooth excavation rock drilling equipment and construction, can solve the problems of inability to be close to surrounding rock to achieve horizontal footage, increase safety risks in the support process, and large degree of rock mass damage and disturbance. problems, to achieve the effect of good work quality, convenient maintenance and reasonable oil circuit design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

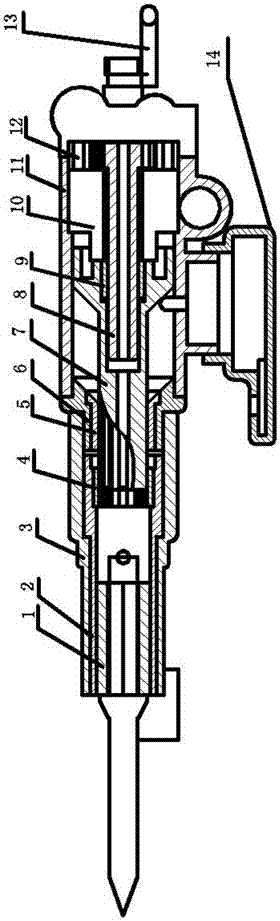

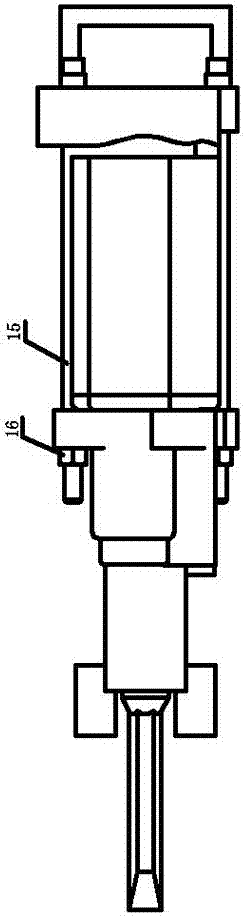

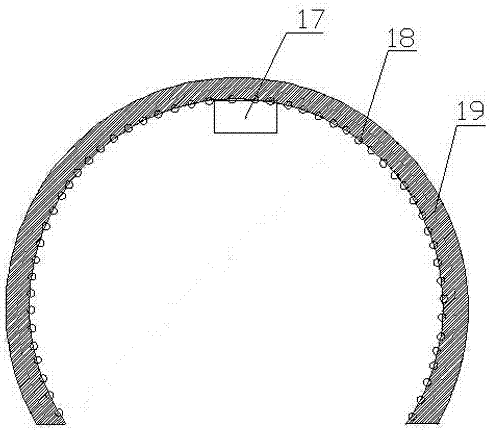

[0024] In order to make it easy to understand the technical means, creative features, objectives and effects achieved by the present invention, the present invention will be further explained below in conjunction with specific drawings.

[0025] See figure 1 with figure 2 , A new type of tunnel smooth excavation rock drilling equipment, including shank (1), rotating sleeve (2), head (3), spline mother (4), bushing (5), guide sleeve (6) , Piston (7), screw rod (8), screw nut (9), valve (10), cylinder (11), ratchet (12), handle (13), long screw (15), nut (16), The upper end of the cylinder (11) is respectively connected with a handle (13) and a machine head (3) via a long screw (15) and a nut (16), and a guide sleeve (6) is provided on the inner wall of the left end of the cylinder (11) ), a bush (5) is provided on the inner wall of the guide sleeve (6), a piston (7) is provided in the cylinder (11), and a screw nut (9) is provided on the inner wall of the right end of the piston ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com