Continuous Fiber Reinforced Unbonded Composite Flexible Pipe

A composite flexible and non-adhesive technology, applied in the direction of rigid pipes, pipes/pipe joints/fittings, hoses, etc., can solve the problems of reducing fluid flow rate, high production cost of pipes, and large friction coefficient, so as to prolong the service life, The effect of avoiding corrosion failure and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

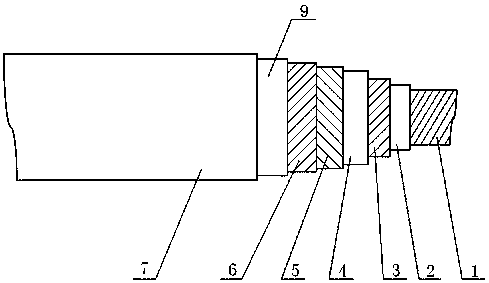

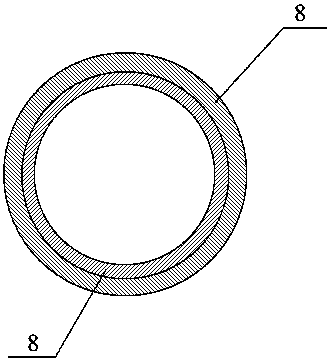

[0030] as attached figure 1 and attached figure 2 The shown invention proposes a continuous fiber-reinforced non-bonded composite flexible pipe, which is respectively provided with a non-metallic inner skeleton layer 1, an inner lining layer 2, a non-bonded reinforcement layer 3, an inner protective layer 4, and an outer layer from the inside to the outside. Skeleton layer 5, tensile layer 6, wear-resistant layer 9 and outer protective layer 7, wherein the non-metallic inner skeleton layer used to ensure uniform bending of the pipe and support the radial load of the pipe is provided with two fiberboard layers 8, from inside to The outer first fiberboard layer 8 is composed of four layers of wrapping tapes, and the second fiberboard layer 8 is composed of six layers of wrapping tapes. The wrapping tapes are composed of thermoplastic resin and fibers. The wrapping tapes in the two fiberboard layers 8 are 72° winding angle, 29mm winding width winding to form a non-metallic inne...

Embodiment 2

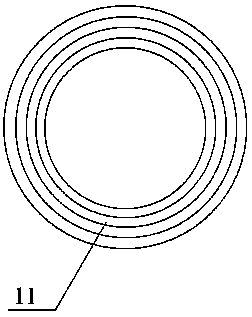

[0040] as attached image 3 The shown invention proposes a continuous fiber-reinforced non-bonded composite flexible pipe, which is respectively provided with a non-metallic inner skeleton layer 1, an inner lining layer 2, a non-bonded reinforcement layer 3, an inner protective layer 4, and an outer layer from the inside to the outside. Skeleton layer 5, tensile layer 6, wear-resistant layer 9 and outer protective layer 7, wherein the non-metallic inner skeleton layer used to ensure uniform bending of the pipe and support the radial load of the pipe is provided with 4 fiberboard layers, from the inside to the outside The first fiberboard layer is wrapped with four layers of winding tape, the second fiberboard layer is wound with six layers of winding tape, the third fiberboard layer is wound with four layers of winding tape, and the fourth fiberboard layer is composed of six layers of winding tape. The winding tapes are composed of thermoplastic resin and fibers, and the windi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com