Novel ammonia refrigeration intercooler

A cooler and ammonia refrigeration technology, which is applied in the field of intercoolers, can solve the problems of unsatisfactory effect, low heat transfer coefficient of coil cooling, incomplete gas-liquid separation, etc., achieve automatic and efficient operation of equipment structure, improve replacement Thermal coefficient, effect of improving work efficiency and work performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

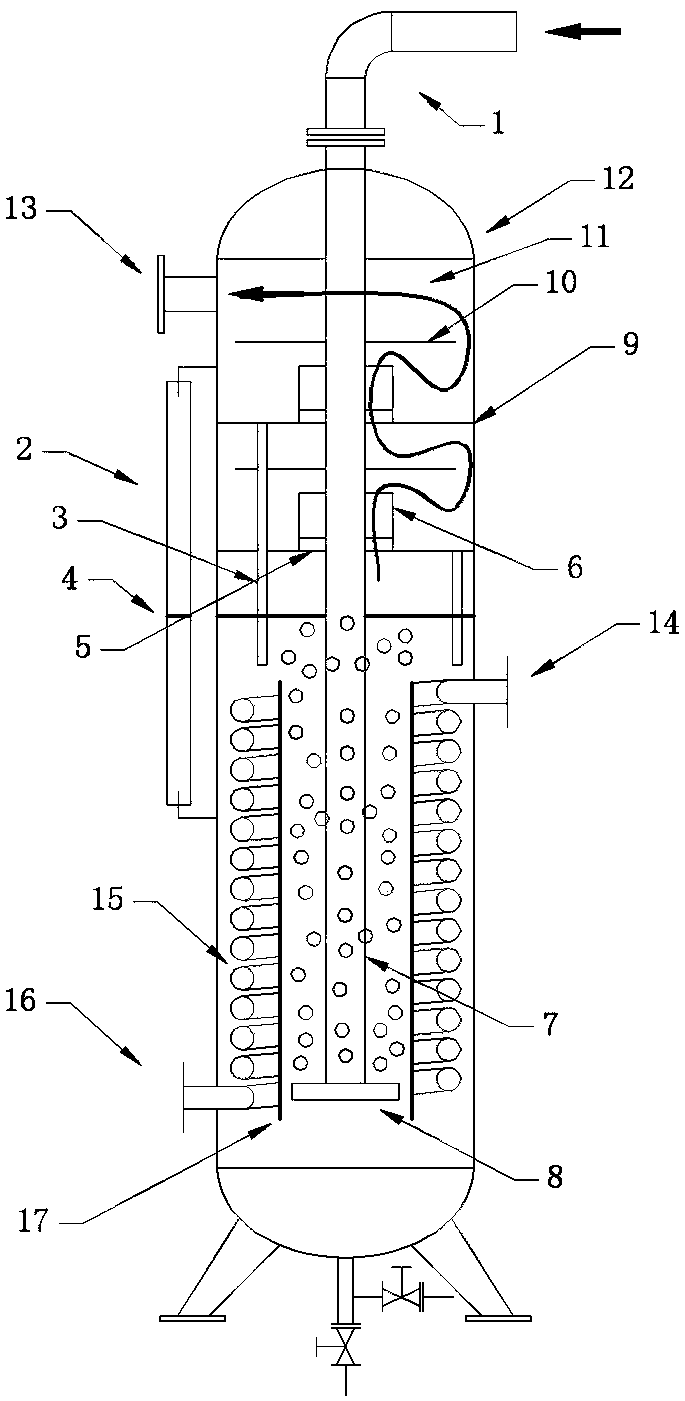

[0028] Now in conjunction with accompanying drawing, the present invention is described in further detail.

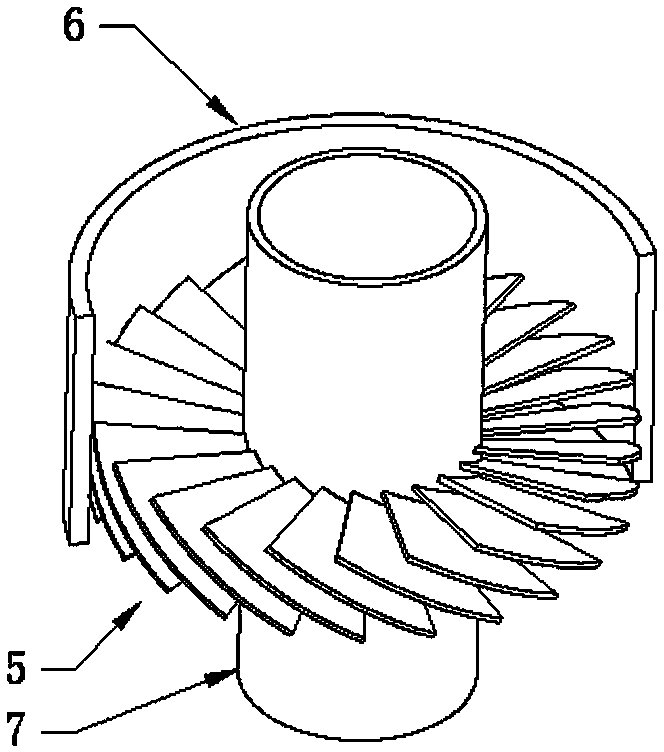

[0029] Such as figure 1 and figure 2 The novel ammonia refrigeration intercooler shown includes a gas-liquid separator tank body 12, a coil 15 for high-pressure ammonia heat exchange is arranged in the intercooler tank 12, and a tubular convection tube 17 is welded at the center of the coil tube; The stage compressed superheated ammonia steam pipe 1 goes deep into the intercooler tank 12 through the air guide pipe 7 and the outlet of the pipe is provided with an air outlet screen cage 8, and the outer wall of the air guide pipe 7 is welded with angled blades 5, and there is a gap between the angled blades. In the gap, a tubular outer cylinder 6 is welded on the blade 5 with an inclination; the intercooler tank body 12 is provided with an isolation plate 9 and a baffle plate 10; the isolation plate 9 separates the tank body so that the ammonia vapor can only flow along...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com