ASE-HPLC method for quickly extracting and measuring low-molecular-weight organic acids in soil

A low-molecular-weight, organic-acid technology, applied in measuring devices, material separation, and analysis of materials, can solve the problems of large solvent consumption, low extraction efficiency, and long extraction cycle, and achieve high extraction efficiency, short extraction time, and easy operation. small error effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

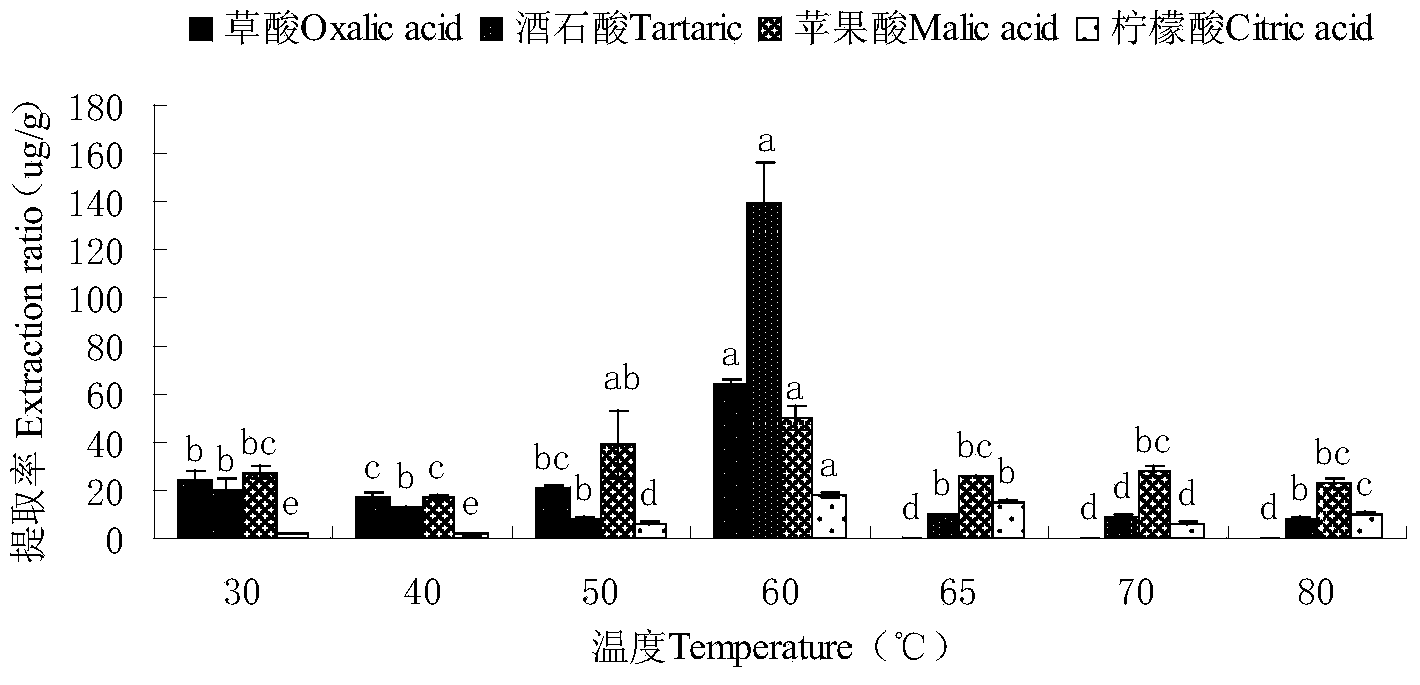

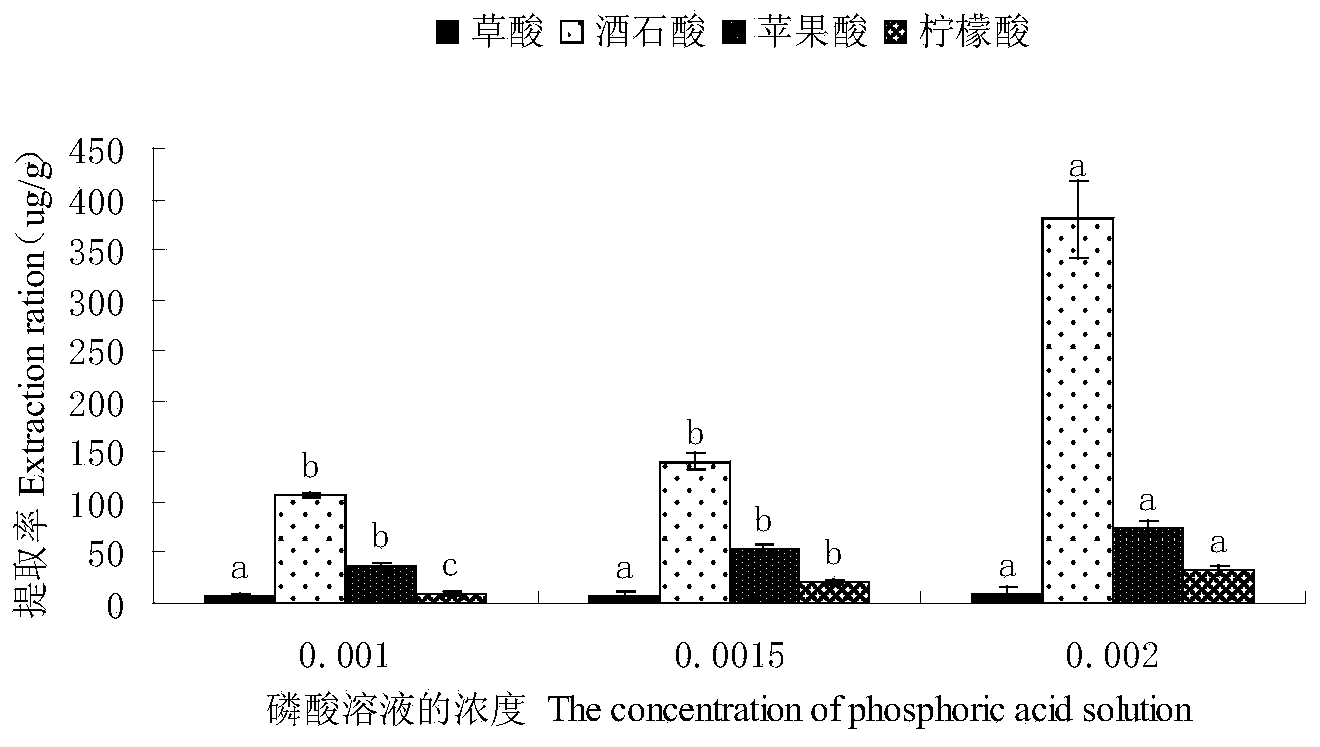

[0027] Firstly, the extraction solvent and extraction temperature parameters of ASE were optimized, and different extraction temperatures (30, 40, 50, 60, 65, 70 and 80°C) were used for extraction experiments. The results show that when the temperature reaches above 65°C (including 65°C), the extraction amount of oxalic acid is 0, referring to the change law of the extraction amount of other organic acids with temperature, it is concluded that 60°C is the best temperature for extracting organic acids ( figure 1 ). The pre-experimental results show that the extraction effect of phosphoric acid solution on soil organic acids is better than that of deionized water, so we selected three concentrations of phosphoric acid solutions of 0.10%, 0.15% and 0.20% to extract organic acids in soil. The results showed that as the concentration of phosphoric acid solution increased, the extraction of various organic acids increased ( figure 2 ). However, because the acid has a certain dama...

Embodiment 2

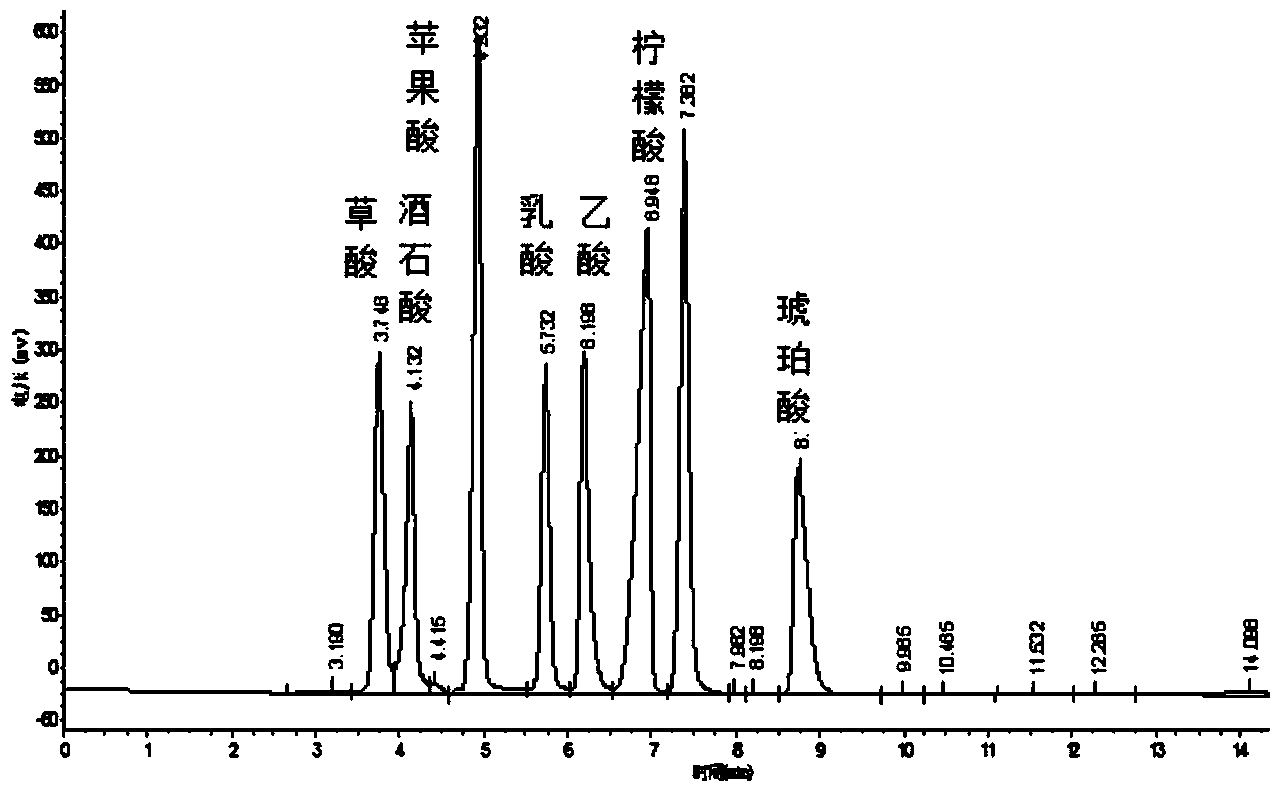

[0029] Accurately weigh 20g of fresh soil samples of continuous cropping orchards passed through a 12-mesh sieve, and 25g of quartz sand (the amount of quartz sand added should be sufficient to disperse the soil samples), and mix them in a mortar. Place a piece of glass cellulose filter membrane on the bottom of the 100ml extraction pool, and put the homogeneously mixed sample into the extraction pool. Extract according to the following conditions: use 0.2% phosphoric acid solution as extractant, pressure 10.3Mpa, temperature 60°C, static extraction time 6min, rinse volume 60% (the amount of rinse solution is 60% of the volume of the extraction pool), purge time 200s, Static cycle 2 times. After the extraction was completed, the extract was transferred to a round-bottomed flask, and evaporated to dryness with a rotary evaporator at 40° C. (preferably until all the water droplets disappeared). Dissolve with 2ml of 0.2% phosphoric acid solution and transfer to a 2ml centrifuge ...

Embodiment 3

[0041] The same fresh soil sample of continuous cropping orchard was used to extract and measure organic acids by ultrasonic extraction method, vibration extraction method and the method of the present invention. Depend on Figure 4 It can be seen that, among the above-mentioned 3 methods of extracting organic acids, the extraction efficiency of the method of the present invention is significantly higher than that of the ultrasonic extraction method and the vibration extraction method, wherein the tartaric acid content measured by the method of the present invention is respectively the ultrasonic extraction method and the vibration extraction method. 6.57 times and 3.17 times of that of oxalic acid, and the content of oxalic acid is 2.67 times and 6.71 times of ultrasonic extraction method and vibration extraction method respectively. The operation is simple and fast (no manual filtration is required, and the error of fully automatic operation is small), the extraction time is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com