Organic electroluminescent display panel, packaging method thereof and display device

An electroluminescence display and display panel technology, which is applied in the directions of organic semiconductor devices, materials and circuits of organic semiconductor devices, can solve the problems of increasing packaging cost and packaging complexity, and achieves increasing packaging cost and packaging complexity, reducing packaging costs and reducing packaging complexity. The effect of lateral water and oxygen erosion area and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

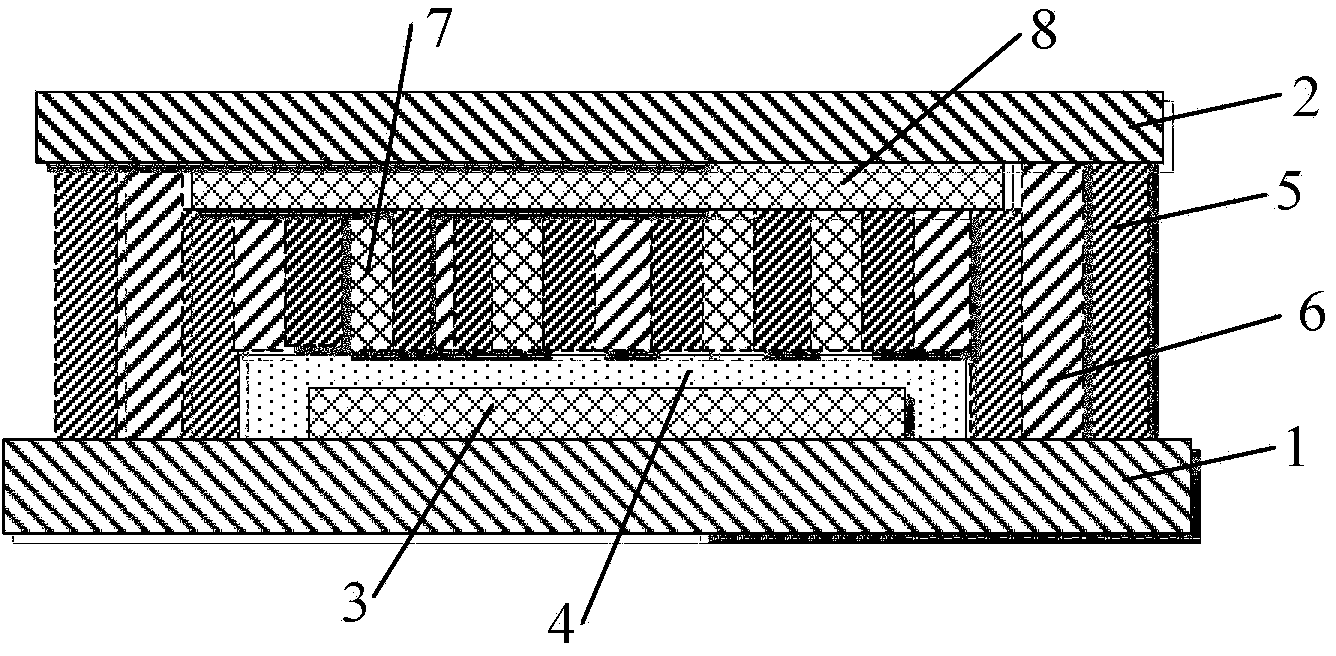

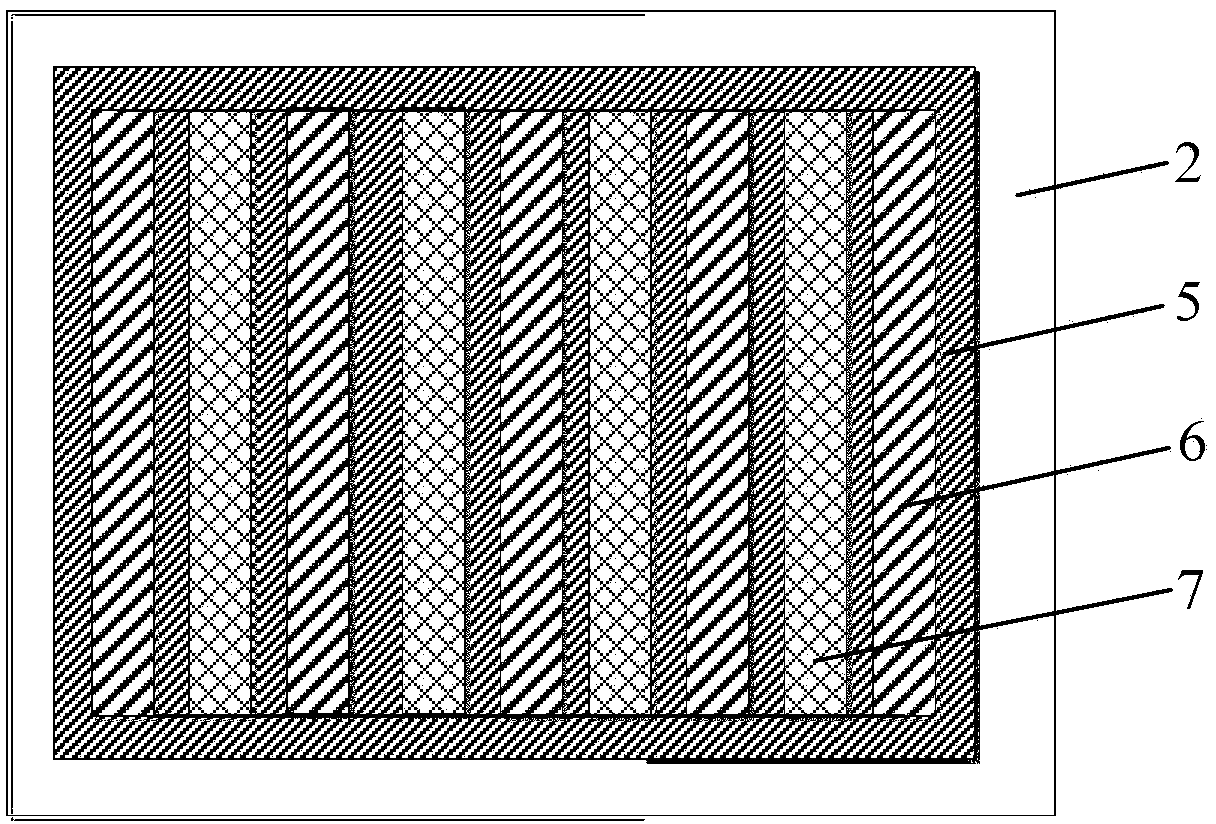

[0034] refer to figure 1 As shown, the organic electroluminescence display panel of this embodiment includes a device substrate 1 and a packaging cover plate 2, the device substrate 1 includes an organic light emitting diode 3, and the organic light emitting diode 3 is covered by a storage cavity 4, and the storage cavity 4 is made of a waterproof material Made to protect the organic light emitting diode 3 from water vapor erosion, and avoid water vapor erosion of the organic light emitting diode 3 in the process of forming other structures in the later stage; an encapsulation protection structure is fabricated between the device substrate 1 and the encapsulation cover plate 2, The packaging protection structure includes multi-layer functional layers that are perpendicular to the device substrate 1 and the packaging cover plate 2 and alternately interspersed. Water layer, it can be understood that the outermost layer described in the embodiment of the present invention means t...

Embodiment 2

[0047] Based on the organic electroluminescent display panel mentioned in Example 1, this example describes the packaging method of this organic electroluminescent display panel. The specific manufacturing steps are as follows: first, prepare the device substrate and packaging cover plate, and Including an organic light emitting diode; then an encapsulation protection structure is formed between the device substrate and the packaging cover plate, the encapsulation protection structure includes a multi-layer functional layer, the multi-layer functional layer is a water blocking layer, and a moisture absorption layer and / or a heat dissipation layer, the function The outermost layer of the layer is a water-blocking layer; each functional layer has multiple layers, and different functional layers are arranged alternately.

[0048] Specifically, in the packaging process of the display panel, a part of the functional layer is firstly formed on the device substrate at intervals, and t...

example 1

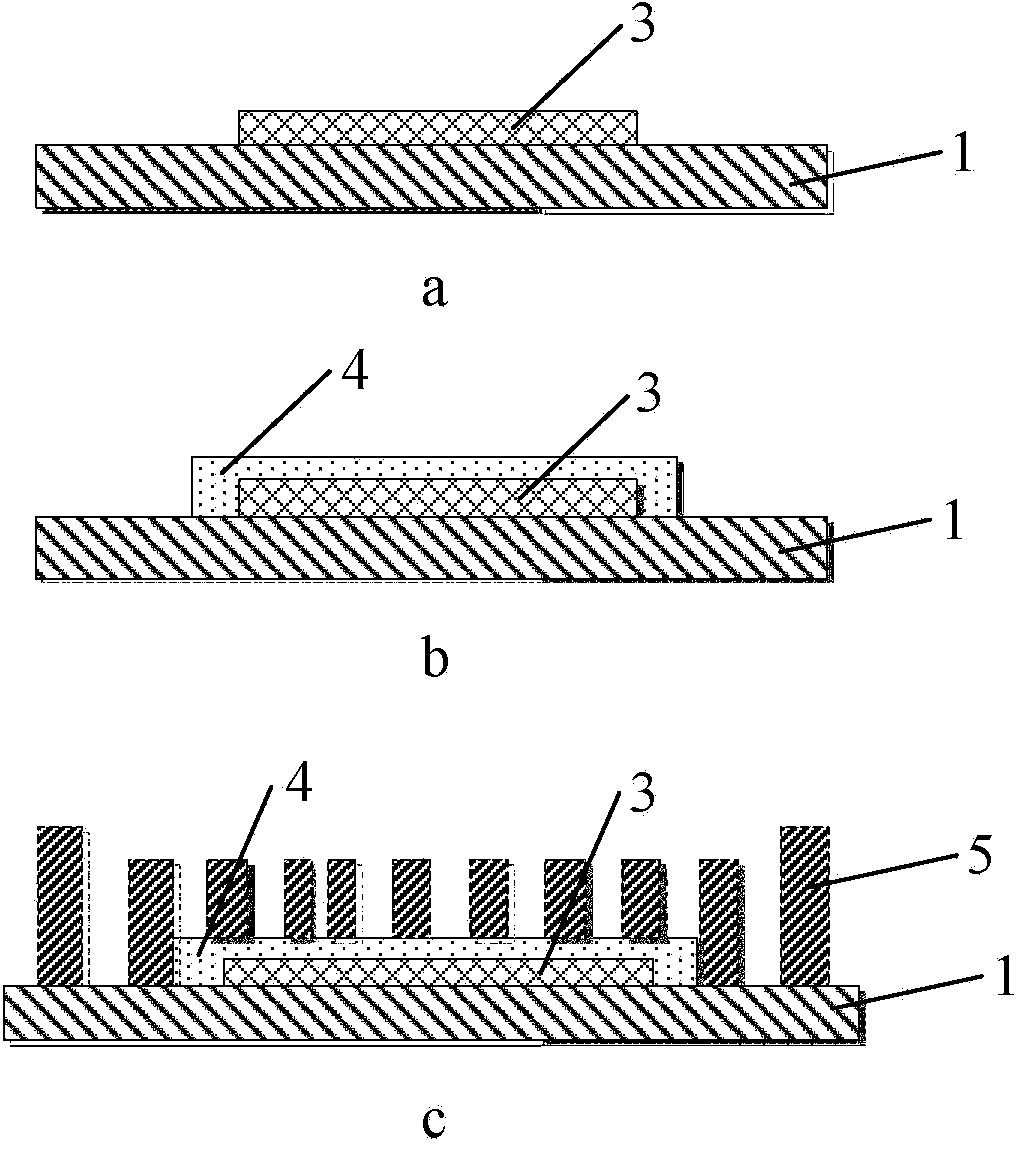

[0051] First, refer to image 3 As shown, an OLED device 3 is sequentially formed on a device substrate 1 ( image 3 As shown in a), the moisture-proof accommodating cavity 4 ( image 3 b), and a multi-layer first functional layer perpendicular to the device substrate 1, wherein the first functional layer is a water blocking layer 5 ( image 3 as shown in c);

[0052] refer to Figure 4 As shown, the buffer layer 8 is sequentially formed on the package cover plate 2 ( Figure 4 a), and the second functional layer perpendicular to the package cover plate 2 ( Figure 4 b) and the third functional layer ( Figure 4 c), wherein the second functional layer is the heat dissipation layer 7, and the third functional layer is the hygroscopic layer 6;

[0053] Secondly, the device substrate and the package cover are pressed together, the moisture absorption layer 6 and the heat dissipation layer 7 are embedded in the gap between the multi-layer water blocking layer 5, and the wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com