Wave-absorbing magnetic-conductive shielding film and manufacture method thereof

A magnetic shielding and waveguide technology, which is applied in the field of wave-absorbing magnetic shielding film and its production, can solve the problems of secondary electromagnetic pollution, electromagnetic shielding film cannot meet the needs, and the thickness of the shielding film is large

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

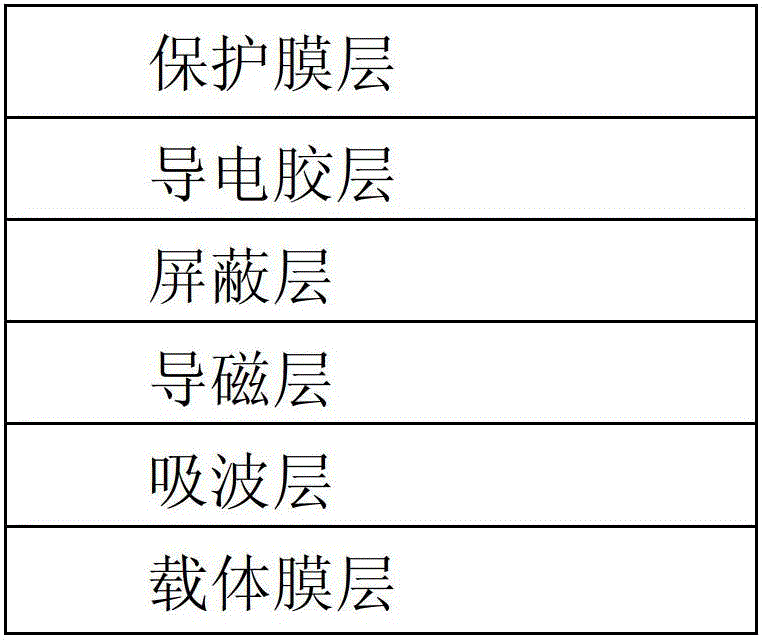

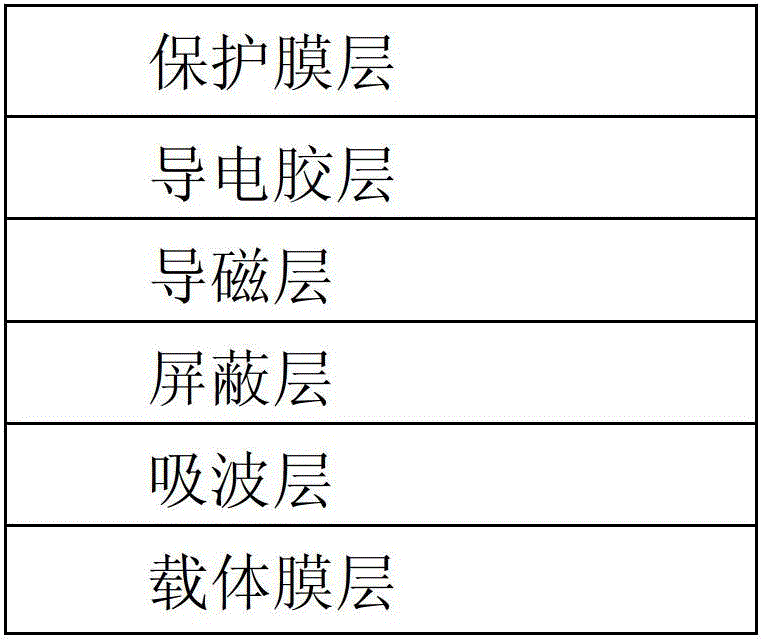

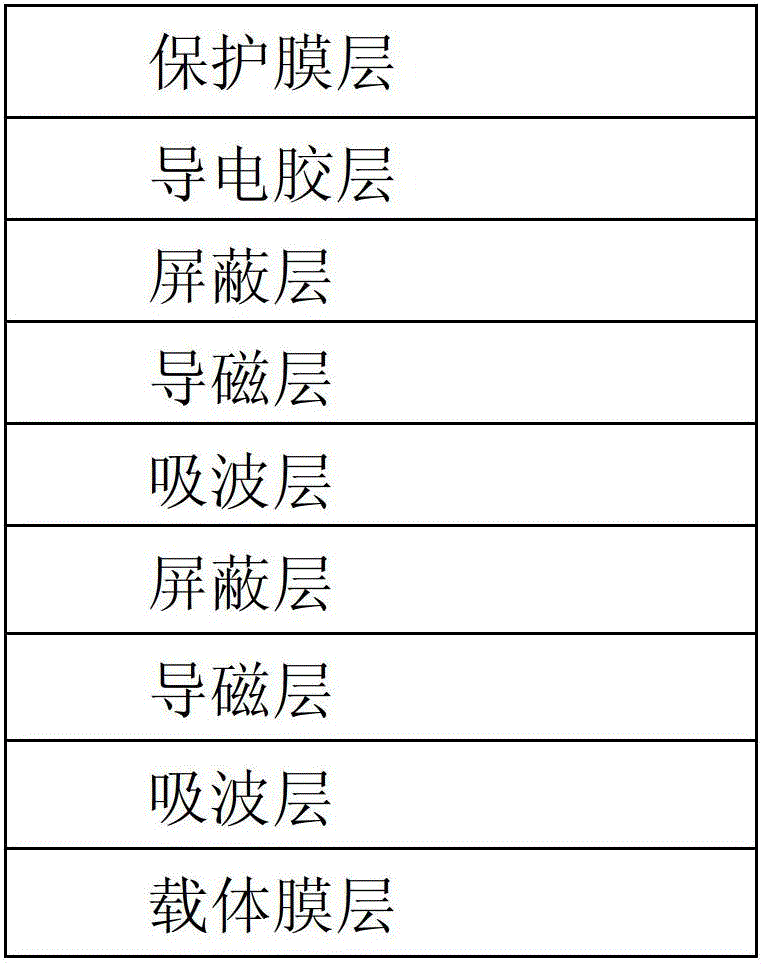

[0059] like figure 1 As shown, the wave-absorbing magnetic shielding film of the present invention includes a carrier film layer 1 , a wave-absorbing layer 2 , a magnetic-conducting layer 3 , a shielding layer 4 , a conductive adhesive layer 5 and a protective film layer 6 from inside to outside.

[0060] 1. Make the carrier film layer:

[0061] 1) Select a PET polyester film with a thickness of 50 μm and a width of 600 mm as the base film layer, and perform corona pretreatment on one side of the film layer. The voltage during the pretreatment process is 20000V, and its surface tension reaches 60 dynes ; Then apply the adhesive layer on the corona-pretreated side surface using ordinary screen printing technology, and dry to form a carrier film layer after coating. The drying temperature is 150°C and the drying time is 50 seconds.

[0062] Wherein, the coating for forming the adhesive layer is selected from epoxy resin and ethyl ester according to the weight ratio of 40:60, an...

Embodiment 2

[0092] like figure 1 As shown, the wave-absorbing magnetic shielding film of the present invention includes a carrier film layer 1 , a wave-absorbing layer 2 , a magnetic-conducting layer 3 , a shielding layer 4 , a conductive adhesive layer 5 and a protective film layer 6 from inside to outside.

[0093] 1. Make the carrier film layer:

[0094] 1) Select a PEN polyester film with a thickness of 50 μm and a width of 600 mm as the base film layer, and perform corona pretreatment on one side of the film layer, wherein the voltage during the pretreatment process is 5000V, and its surface tension reaches 35 dynes ; Then, the corona pretreated side surface is coated with an adhesive layer using micro-gravure technology, and after coating, it is dried to form a carrier film layer. The drying temperature is 200 ° C, and the drying time is 60 seconds.

[0095] Wherein, the coating for forming the adhesive layer is selected from epoxy resin and ethyl ester according to the weight rati...

Embodiment 3

[0120] like figure 1 As shown, the wave-absorbing magnetic shielding film of the present invention includes a carrier film layer 1 , a wave-absorbing layer 2 , a magnetic-conducting layer 3 , a shielding layer 4 , a conductive adhesive layer 5 and a protective film layer 6 from inside to outside.

[0121] 1. Make the carrier film layer:

[0122] Except that the voltage in the corona pretreatment process is 10000V to make the surface tension reach 40 dynes, the drying temperature is 180°C, the resin content in the subsequent layer is 20%, and the thickness of the subsequent layer is 5 μm, the rest are the same as in the embodiment 1 is the same.

[0123] 2. Overlay absorbing layer:

[0124] On the surface of the adhesive layer, continue to apply the wave-absorbing coating by means of rubber rollers, with a coating thickness of 50 μm, and dry to form a wave-absorbing layer after coating. The drying time is 5 minutes, and the drying temperature is 200 ° C.

[0125] Wherein, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com