The preparation method of vegetarian meat floss

A vegetarian and meat floss technology, which is applied in the field of two kinds of shredders and vegetarian meat floss, can solve the problems of poor imitation meat, inconvenient operation, unevenness, etc., to reduce the powdery feeling, the sensory fibers are slender, and the taste of the meaty fiber feeling. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

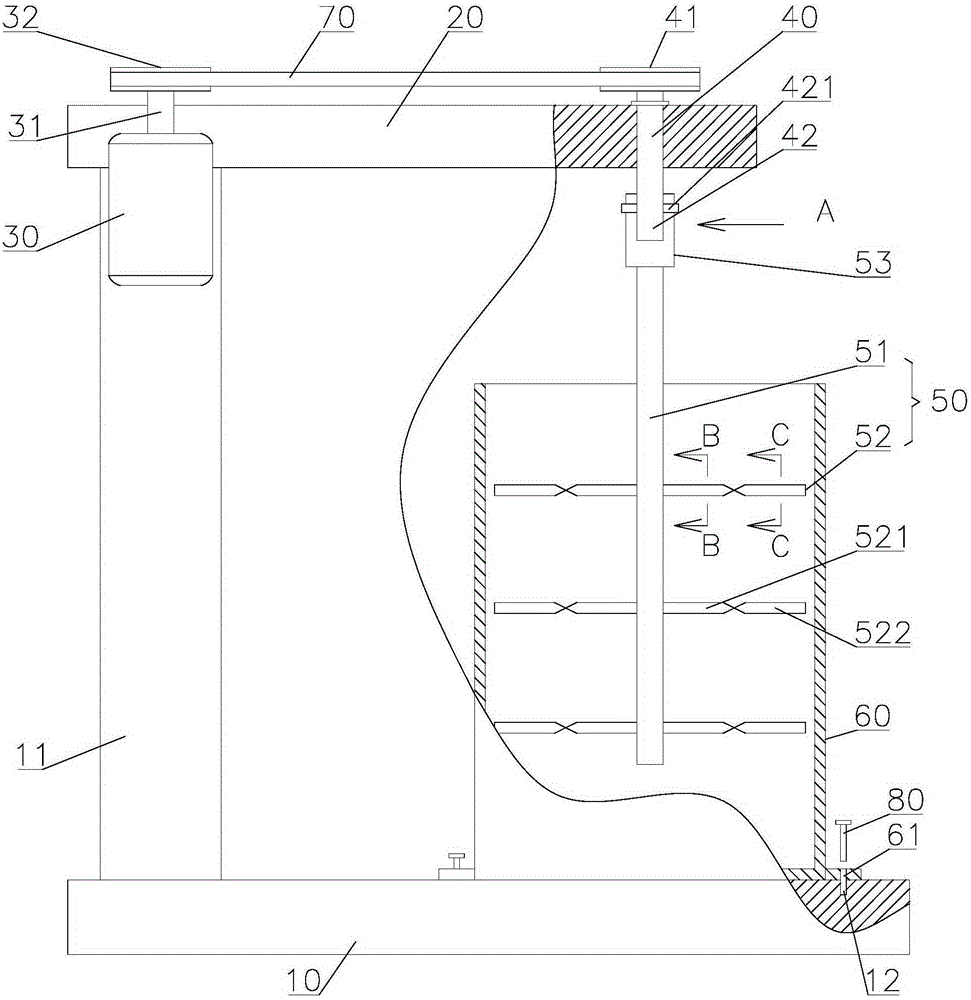

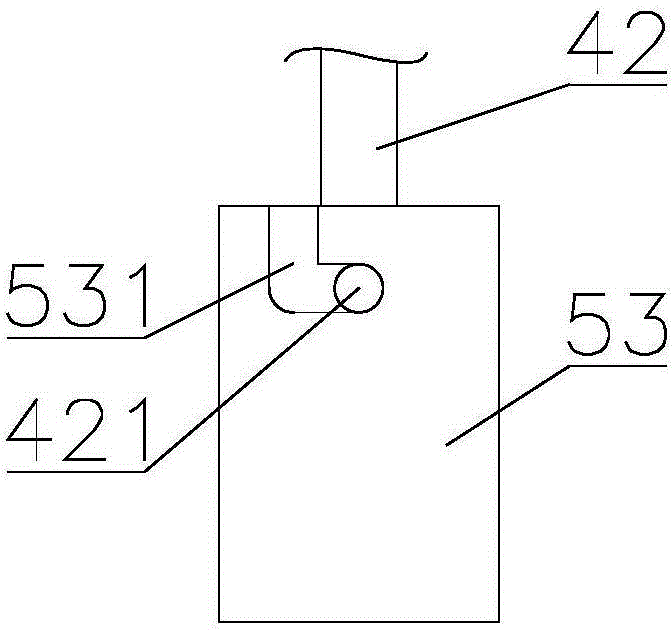

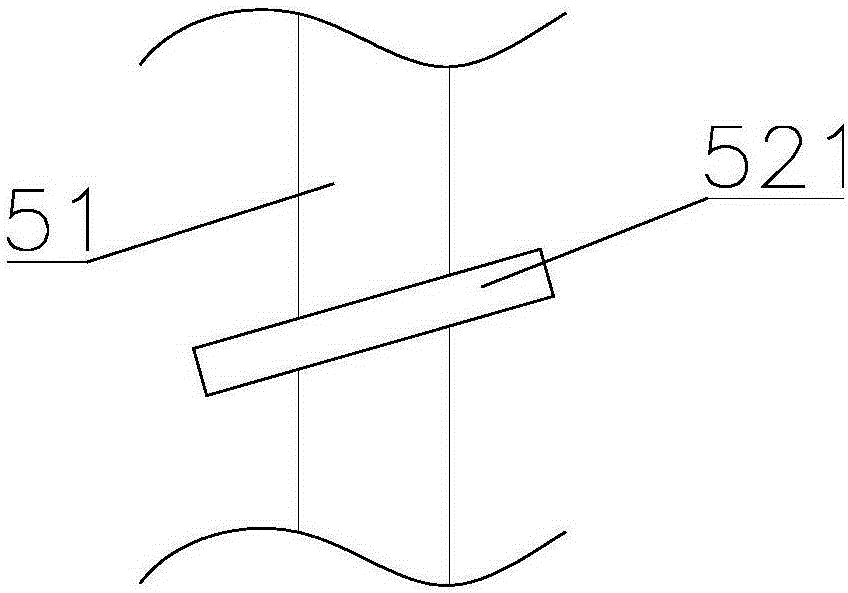

Image

Examples

Embodiment 1

[0037] Vegetarian meat floss (mushroom flavor), its raw material components include: soybean tissue protein 30kg, soybean powder 20kg, corn starch 10kg, soybean vegetable oil 15kg, white sugar 10kg, sesame 2kg, laver 2kg, seasoning 5kg. The seasoning comes with fried diced shiitake mushrooms.

[0038] Concrete preparation method comprises the following steps:

[0039] 1) Rehydrate the soybean tissue protein, that is, soak it in 120kg of water until it is completely thorough and free of hard lumps.

[0040] 2) Pour the textured soybean protein into the stirring wire dismantling machine, and disassemble it at a speed of 300r / min for at least 1min. Grab the textured soybean protein with hands until there is no flakes, lumps, or filaments. .

[0041] 3) Use a dehydrator to dehydrate at a speed of 200r / min for 3 minutes, rinse the soybean textured protein with water, dehydrate and then rinse with water, repeat the above operation at least 3 times until no water flows out from the...

Embodiment 2

[0045] Vegetarian meat floss (coconut flavor), its raw material components include: soybean textured protein 38kg, soybean powder 26kg, corn starch 15kg, soybean vegetable oil 19kg, white sugar 12kg, sesame 4kg, laver 3kg, seasoning 6kg. The seasoning comes with toasted shredded coconut.

[0046] Concrete preparation method comprises the following steps:

[0047] 1) Rehydrate the soybean tissue protein, that is, soak it in 152kg of water until it is completely thorough and free of hard lumps.

[0048] 2) Pour the reconstituted soybean textured protein into the stirring wire dismantling machine, and disassemble it at a speed of 400r / min for at least 1min. Grab the soybean textured protein with hands until there is no flakes, lumps, or filaments. .

[0049] 3) Use a dehydrator to dehydrate at a speed of 250r / min for 5 minutes, rinse the soybean textured protein with water, dehydrate and then rinse with water, repeat the above operation at least 3 times until no water flows out...

Embodiment 3

[0053] Vegetarian meat floss (seaweed flavor), its raw material components include: soybean texture protein 45kg, soybean flour 30kg, corn starch 20kg, soybean vegetable oil 25kg, white sugar 15kg, sesame 5kg, seaweed 5kg, seasoning 10kg. This seasoning comes with fried seaweed.

[0054] Concrete preparation method comprises the following steps:

[0055] 1) Rehydrate the soybean tissue protein, that is, soak it in 180kg of water until it is completely thorough and free of hard lumps.

[0056] 2) Pour the water-reconstituted soybean textured protein into the stirring wire dismantling machine, and disassemble it at a speed of 500r / min for at least 1min. Grasp the soybean textured protein with hands until there is no flake, block, or filament. .

[0057] 3) Use a dehydrator to dehydrate at a speed of 300r / min for 8 minutes, rinse the soybean textured protein with water, dehydrate and then rinse with water, repeat the above operation at least 3 times until no water flows out fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com