X-ray clean coal gangue inorganic sulfur water-free separation equipment

A technology of inorganic sulfur and coal gangue, which is applied to the separation of solids from solids by air flow, sorting, solid separation, etc., and can solve the problem of non-moisture-free selection of optional coal, difficult coal selection, small market share, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

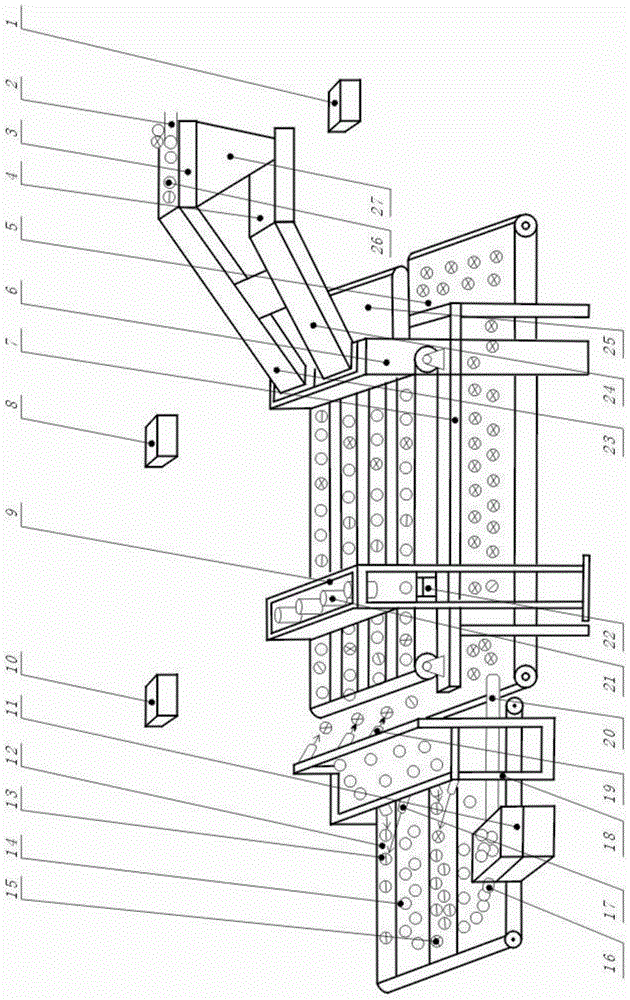

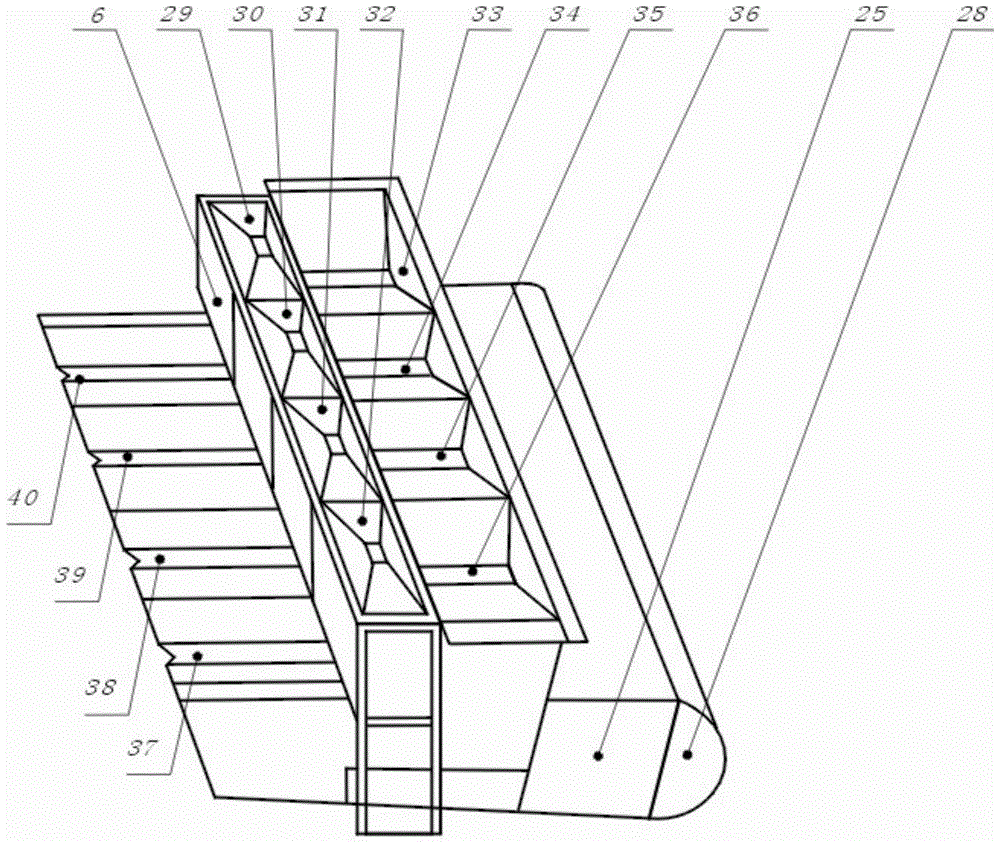

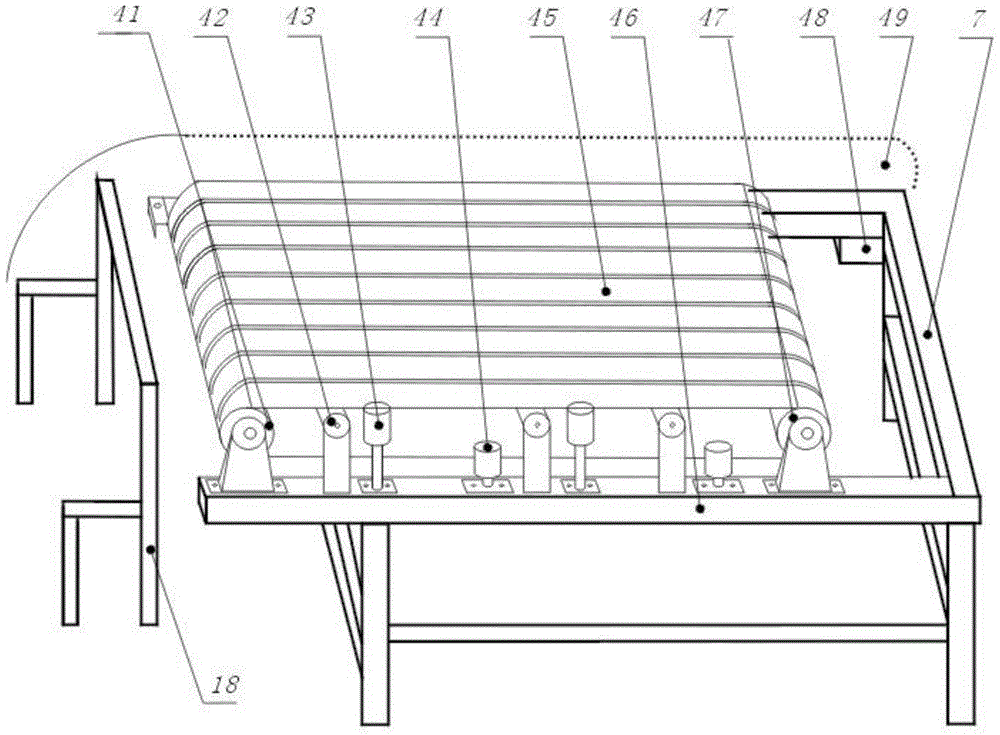

[0024] see figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 , the present embodiment includes equipment and facilities arranged in four different altitudes at the coal mine wellhead or on the ground coal transportation line and sequentially connected in series: the equipment at the first altitude (the highest altitude) has a large-grain linear vibrating screen system 3 and a raw coal block In the coal supply system 2, a small-grain linear vibrating screen system 4 is installed at the second altitude, and a vibrating screen funnel 27 is installed between the first altitude and the second altitude. The raw coal or lump coal 26 passes through the large-grain linear vibrating screen system. 3 and the small-grained linear vibrating screen system 4 enter the grading coal queuing system 6 at the third altitude, and between the second alt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com