Integrated apparatus for treating high-concentration chemical flooding oil field wastewater by strong oxidation gas wet contact method

A technology of oil production wastewater and contact method, which is applied in the direction of oxidation water/sewage treatment, mining wastewater treatment, etc., can solve the problems of high treatment cost and difficult industrialization, and achieve the effect of avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

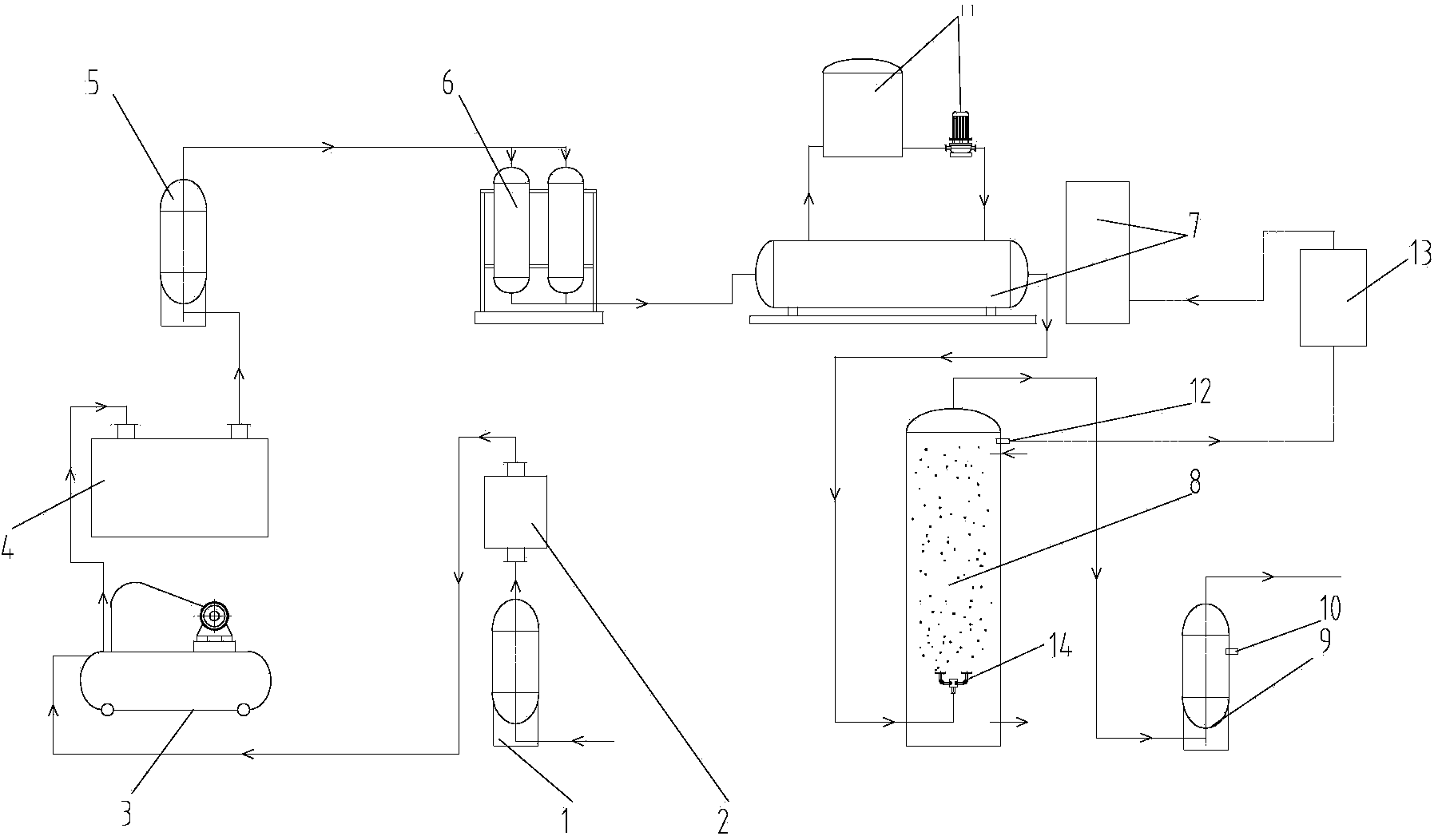

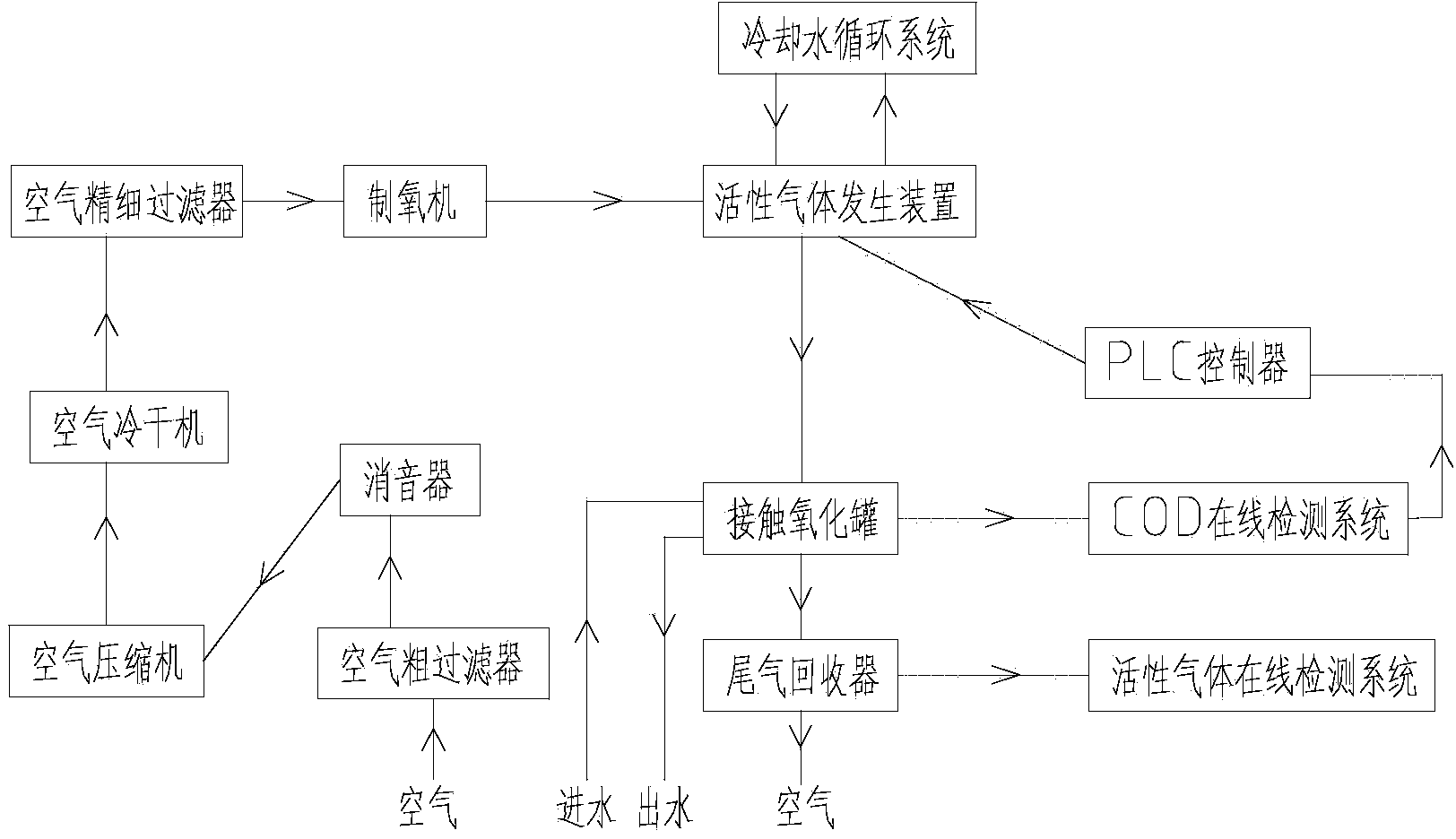

[0009] attached by figure 1 , attached figure 2 As shown, the integrated device for treating high-concentration chemical flooding oil field oil production wastewater by strong oxidizing gas wet contact method includes a coarse air filter 1, which is connected to a silencer 2, an air compressor 3, and an air cooling dryer in sequence through pipelines 4. Fine air filter 5, oxygen generator 6, active gas generating device 7, contact oxidation tank 8, tail gas recoverer 9, wherein: the tail gas recoverer 9 is equipped with an active gas online detector 10, and the active gas generating device 7 Connected with a circulating water cooling system 11, a COD on-line monitor 12 is installed on the contact oxidation tank 8, and the COD on-line monitor 12 and the active gas generating device 7 are connected to the PLC controller 13 signal lines respectively, and the COD on-line monitor 12 is connected to the incoming water. The COD value is converted into an electrical signal and trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com